products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

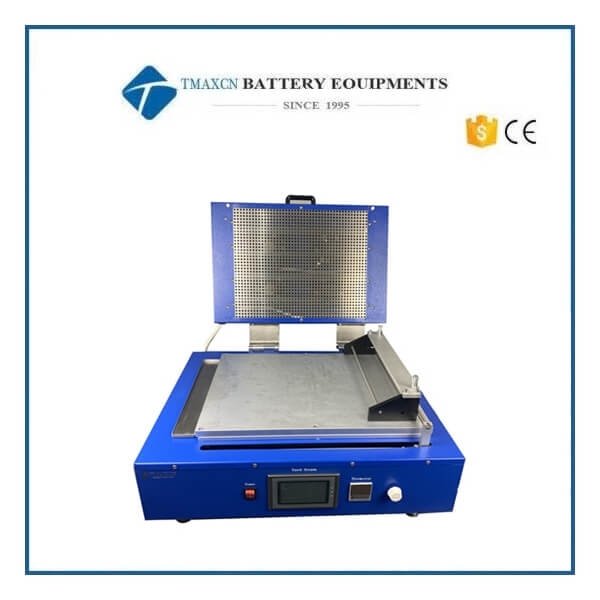

200C Max. Compact Lab Automatic Mini Tablet Film Coater ( 10"Wx16"L ) For Battery Electrode Coating

Model Number:

TMAX-H200TCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Compact Tape Casting Coater w/ Vacuum Chuck (8"Wx14"L), Film Applicator & Optional 100ºC Dryer CoverNext:

Laboratory Thin Film Flow Coater Coating Machine With Infinitely Variable Speed

200C Max. Compact Lab Automatic Mini Tablet Film Coater( 10"Wx16"L ) For Battery Electrode Coating

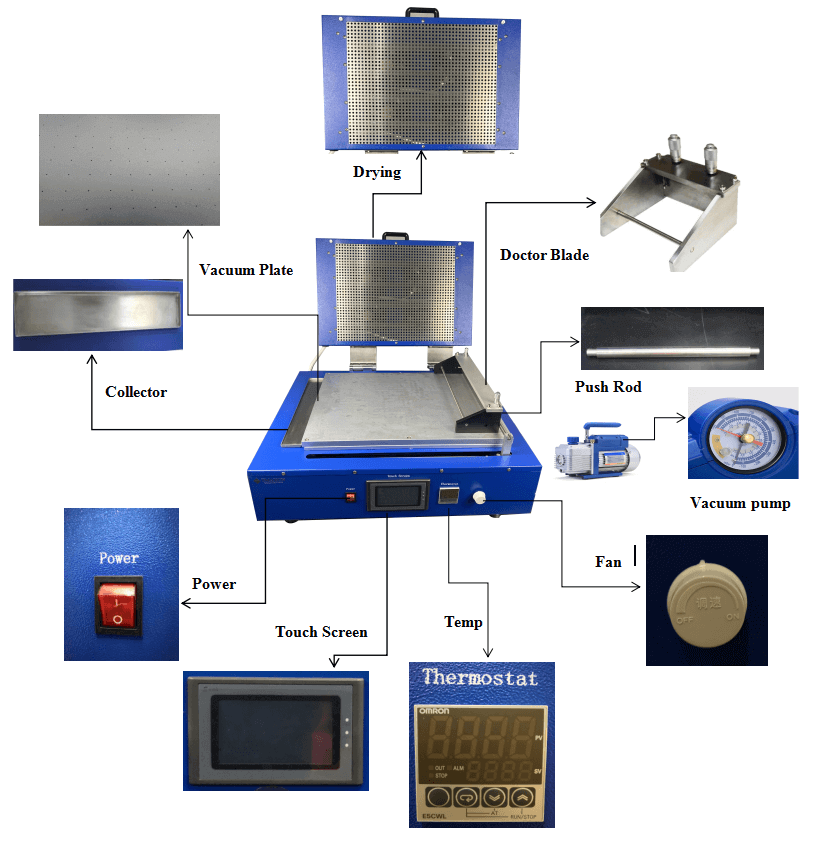

TMAX-H200T is an NRTL standard Compact Tape Casting Coater with the vacuum chuck hotplate up to 200ºC and the active carbon filter on the top cover to protect lab environment. It is an excellent tool to make high-temperature polymer coating or conductive ceramic film on various substrates. Choosing the best bar coater from our company.

SPECIFICATIONS:

Model |

TMH250 |

TMH300 |

TMH350 |

TMH550 |

TMH800 |

TMHXXX |

Effective Coating Size |

100*250mm |

200*300mm |

250*350mm |

250*550mm |

250*800mm |

customized |

Machine Weight |

80kg |

100kg |

115kg |

130kg |

160kg |

N/A |

Accessories: Film Applicator |

Optional 50 up to 300 mm width micrometer film applicator is included Or customized |

|||||

Optional Heating Cover Voltage and Power |

110VAC or 220VAC |

|||||

Traverse Speed |

0 - 120 mm/sec variable

Accuracy: 10mm/sec |

|||||

Vacuum Pump |

Vacuum pump is included |

|||||

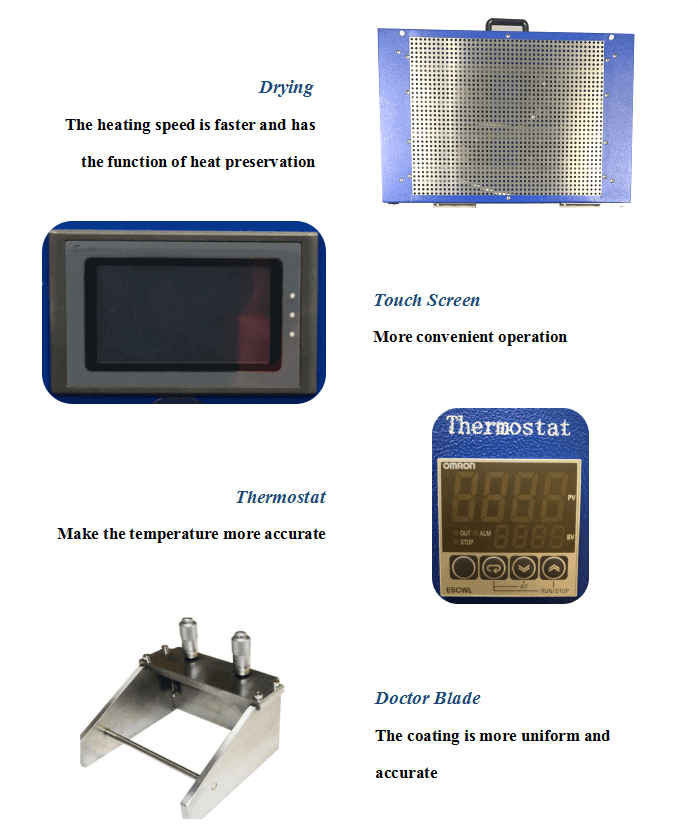

Heating Cover |

1. Pre-installed on the top cover

2. Built in digital temperature controller with accuracy of +/-1°C

3. Suspension support helps open cover easily and safely

4. Max. Heating Temp: 200°C |

|||||

Compliance |

CE Certificate |

|||||

Warranty |

Two years limited warranty with lifetime support |

|||||

Operating procedures |

1. Put the Electrode on the vacuum plate, start the power supply, open the vacuum, the electrode adsorption on the vacuum plate.

2. Place the film applicator on the electrode and add the coating slurry.

3. Open the film, the film device automatically pushes the film applicator to move, automatic film.

4. Take out the film applicator and push rod, cover with the heating cap, set the heating temperature and time, and heat and dry.

5. After drying, open the heat cover, take out the coated film electrode, film device reset complete.

|

|||||

Maintenance method and matters needing attention |

1. Every time before work to use a soft cloth with alcohol carefully wipe the film head, the body, keep clean.

2. Film head, differentiator and other high-precision parts of the use do not collide, gently take gently, differentiator to adjust the left and right to be symmetrical and even.

3. Regularly check screws, nuts, pins and other fasteners in various parts to prevent looseness and prevent product quality accidents. |

|||||

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588