products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automated Sealing Equipment for Prismatic Cells Production

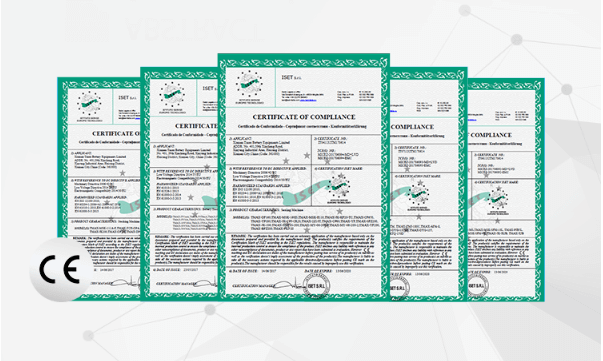

Model Number:

TMAX-ZTH-08Compliance:

CE CertifiedWarranty:

1 yearMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Battery Producition Automatic Conveyor LineNext:

5V 30A/60A/80A/120A/200A/300A Prismatic Cell Automatic Negative Pressure Formation and Grading Machine

Automated Sealing Equipment for Prismatic Cells Production

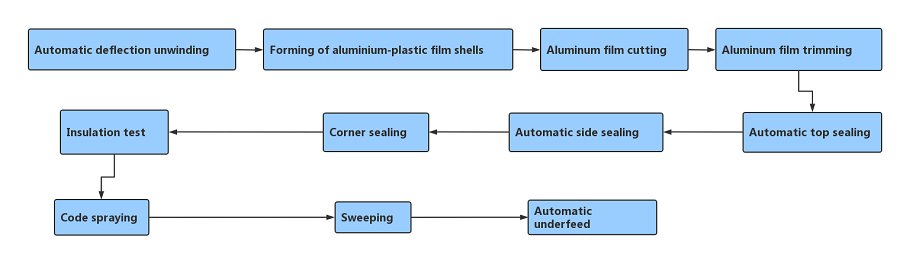

Workflow

Specification

Project |

Parameters |

Aluminium film punching method |

3-piece film method, top pressing and bottom topping |

Film feeding method |

Servo feeding, feeding accuracy ≤ +0.1mm |

Punching pattern |

Servo punching shell, adjusting accuracy ≤±0.1mm, can punch single and double pits, simultaneous adjustment |

4-corner error of aluminium film punching |

≤±0.15mm |

Alignment accuracy of the top and bottom of the aluminium film |

≤±0.5mm |

Sealing mode |

Heat encapsulation |

Sealing drive |

Servo pressure mode, with cylinders on 2 sides of the head as pressure adjustment |

Head temperature control accuracy |

±3°C |

Head operating temperature range |

170~200°C |

Coding machine |

Inkjet |

Production efficiency |

Model 150 ≥12ppm; Model 300 ≥8ppm |

Conformity rate |

≥99% |

Crop rate |

≥98% |

Dimension |

W7000 × L3000×H2350mm |

Weight/load |

>750Kg/M2 |

Power supply |

AC380V three-phase;voltage fluctuation±10%;power:20KW;frequency:50Hz |

Compressed air |

0.5~0.7Mpa ( 5~7kgf/cm2 ), dosage 400L/min |

Model |

TMAX-ZTHFZX-150 |

TMAX-ZTHFZX-300 |

Cell length |

45~150mm |

120~300mm |

Cell width |

35~100mm |

80~200mm |

Cell thickness |

3~10mm |

4~12mm |

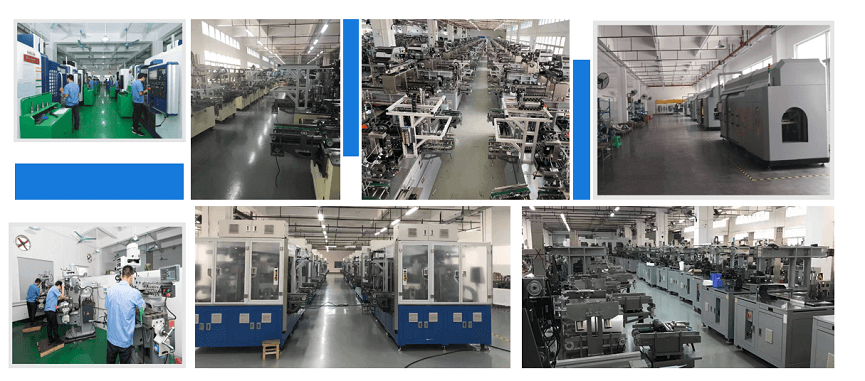

Production Assembly Plant

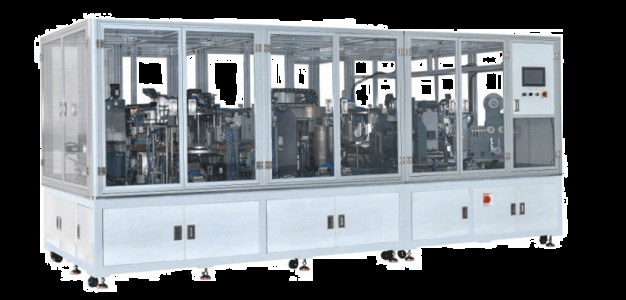

Detailed Images

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588