products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

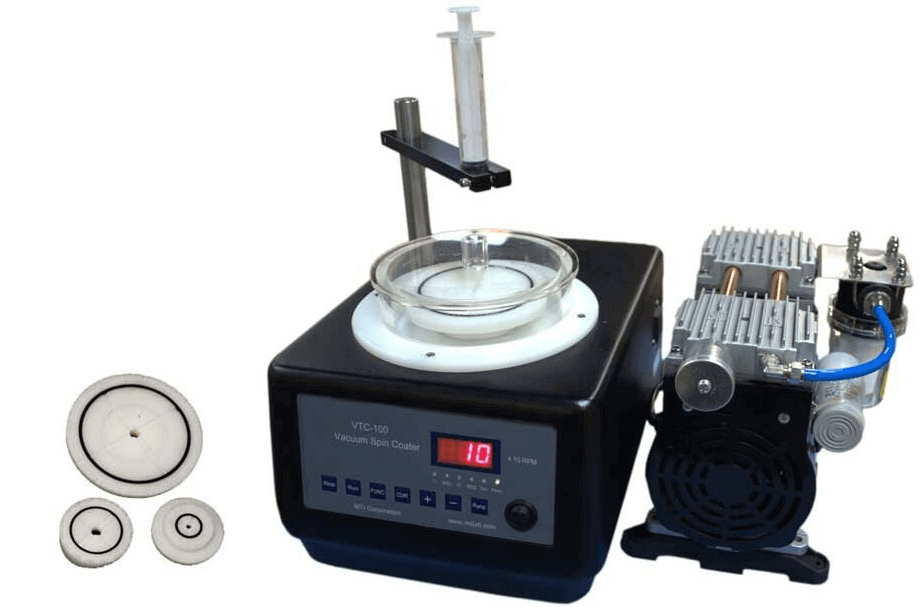

Compact Spin Coater ( Max. 8000 rpm, 4" wafer Max.) with 3 Sets of Vacuum Chucks & Complete Accessories

Model Number:

TMAX-VTC-100ACompliance:

CE CertifiedWarranty:

1 yearPlace of Origin:

Fujian, China (Mainland)Shipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Programmable Hi-Speed Spin Coater (10K rpm & 5" max) with Vacuum Chucks (Optional Heating Cover)Next:

Economic Desktop Spin Coater (Max. 8000 rpm) with Complete Accessories

Compact Spin Coater ( Max. 8000 rpm, 4" wafer Max.) with 3 Sets of Vacuum Chucks & Complete Accessories

Specifications:

Structure |

· Aluminum casting case to keep spinning stable · Liquid disk made to resist most of the corrosive solutions · Drainage outlet and vacuum pump connector are on back panel · One filter is included in standard package. It is used to connect the coater for preventing waste water flowing into the pump · One oil-less vacuum pump is included in the standard package |

|

· Chamber Diameter: 145 mm · 3 sets of PP anti-corrosive vacuum chucks with chuck o-ring come in different sizes (1'', 2'' and 4'') · 1 piece of adhesive tape (6'' W x 24'' L) is included for coating irregularly shaped substrates (e.g. Place the irregular substrate on the adhesive tape, then the vacuum chuck will hold the tape by suction) · Mini suction cups are available for the small wafer with less 1" Dia. or substrate with regular ( 5x5, or 10x10mm) or irregular shape. |

Vacuum Pump |

· Vacuum grade rubber pipe is included for immediate use |

|

· Digital control panel with TWO programmable segments for different spin times and speeds · Spinning speed: 500 - 8000 RPM · Spinnning Time: 1 - 60s |

Liquid Injecting |

· 20mL syringe is used to contain the coating material · The syringe holder height can be adjusted and rotated freely along the support rod |

Optional |

· You may choose Precision Electronic Single Channel Pipette: 20 - 200uL for more accurate coating · Using plasma cleaner to treat substrate surface before coating can improve film quality · You may consider our new product: Heatable syringe · Vacuum Flash Assembly for DIY Vacuum Flash-Assisted Solution Process (VASP), Up to 5 mTorr is available |

Input Power |

110VAC or 220VAC please select the voltage in options bar (10A fuse) |

Motor Power |

24V DC motor with 150W Max. |

Product Dimensions |

13''(L) x 10''(W) x 8.5''(H) |

Net Weight |

15 kg (33 lbs) |

Compliance |

· CE Certified |

Warranty |

· One year limited with lifetime support · Rusting and damage due to improper storage condition or maintenance are not covered by warranty |

Shipping Weight |

46 kg (100 lbs) |

|

· In order to achieve optimal coating quality, please consider cleaning substrates by a plasma cleaner prior to coating. This will significantly reduce the surface tension on the substrates. · Cleaning instruction for the spin coaters. · You may consider our new product: Heatable syringe and spin coater with heatable cover · Strongly suggest you put the coater under a fume hood as below right · When using the coater in glovebox with Ar gas, vacuum pump must put in outside the glovebox via vacuum feedthrough or adaptor |

Warnings |

· Do not overflush the water bowl/base with any kinds of liquid. Excess liquid will leak into the motor shaft and cause damage. Please use fabric cloth to wipe out the residues remain in the bow/base. · If necessary, turn on the water outlet when flushing the water bowl/base to avoid liquid overflowing during the operation. |

Shipping Dimensions |

40"(L) x 28"(W) x 24"(H) |

Shipping Weight |

46 kg (100 lbs) |

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588