products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

(Dia 800*950mm)Auto Rolling Press Machine/Cell Calender for Battery Production Line

Model Number:

TMAX-DYG-703BH1-Φ800Input Power:

72KWDimension(L*W*H):

8000*4720*3200mmNet Weight:

32TCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportPlace of Origin:

ChinaPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

90 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

High Speed Continuous Slitter w Roll to Roll System for Battery Anode and Cathode Electrode PreparationNext:

300L Planetary Vacuum Mixer for Battery Production Line

(Dia 800*950mm)Auto Rolling Press Machine/Cell Calender for Battery Production Line

A.Equipment functions:

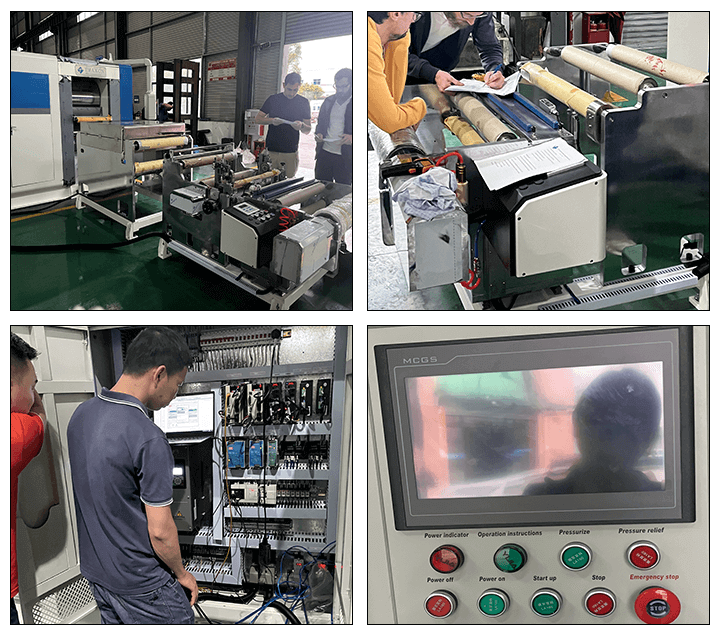

1. This set of equipment is connected by a standard roller aligning machine, which is suitable for the high-speed tablet pressing process of continuous pole coating. This set of equipment is mainly composed of a single station unwinding part, a front and rear tension stretching part, an oil pressure roller aligning host part, an online thickness measurement system, and a single station rewinding part.

1) This machine has a mouth shaped integrally cast 45# steel frame, large slider structure, large bearing capacity, small deformation, large rolling force and high rolling speed;

2) By using the constant pressure limited gap rolling method, the battery pole pieces with longitudinal blank and continuous coating can be rolled continuously;

3) Scraper device with roller surface cleaning mechanism;

4) With servo motor unwinding device;

5) Equipped with manual tape receiving platform;

6) With pole slice trimming mechanism;

7) With tension buffer mechanism;

8) It has the function of dust and iron removal by pole brush;

9) With front tension stretching and rear tension stretching devices;

10) The hydraulic system adjusts the lift of the oil cylinder through the human-computer interface touch screen to drive the lift of the roll;

11) Adjust and change the pressure of the roll cylinder through the man-machine interface, control the constant pressure, and the man-machine interface displays the actual pressure;

12) The up and down movement value of the roll is displayed on the man-machine interface screen;

13) The roll surface is plated with hard chromium, and the thickness of chromium layer after grinding is ≥ 120um;

14) Rolling speed ≥ 50m/min;

15) Roll removal device;

16) Laser on-line thickness measurement function;

B. Applicable material conditions:

1、Incoming material specification (Unit:mm)

Specifications Material |

incoming |

Coil width |

Thickness |

Internal diameter |

Maximum outside diameter |

Max capacity |

Positive electrode |

Coil material |

300~850 |

0.060~0.300 |

6〞 |

Φ800 |

800kg |

Negative pole |

Coil material |

300~850 |

0.065~0.300 |

6〞 |

Φ800 |

800kg |

Positive foil area |

—— |

300~850 |

0.009~0.035 |

—— |

—— |

—— |

Negative foil area |

—— |

300~850 |

0.006~0.035 |

—— |

—— |

—— |

1. Material system: positive pole: lithium iron phosphate system / ternary system / lithium manganate system; negative pole: Graphite System / silicon carbon system;

2. Coating method: continuous single banner coating, continuous multiple zebra coating, single gap coating, multi gap coating, etc;

3. Foil specification: copper aluminum foil / carbon coated copper aluminum foil;

C. Installation requirements for whole line equipment :

1) Power requirements: 380V/50hz, power about 72KW;

2) Compressed air: pressure 0.5mpa~0.7mpa, flow: 0.04m3/min;

3) The total weight of the equipment is about 32T. The ground bearing requirements for the installation of the roller machine host are >8T/m2, and the ground bearing requirements for the unwinding and rewinding installation are >2.5 T/m2.

4) Overall dimension of connecting equipment (mm): length * width * height (8000*4720*3200), subject to site layout.

D.Equipment performance index:

No. |

Entry name |

Performance index |

Remarks |

1 |

Production speed of complete equipment |

≥50m/min |

Acceptance speed |

2 |

Pole or foil type |

Non ferrous precious metals such as copper or aluminum |

|

3 |

Roll specification |

φ800*950mm |

|

4 |

Maximum rolling force |

400T |

|

5 |

Effective rolling width |

850mm |

|

6 |

Evenness of pole piece after rolling |

≤±0.002mm(Required incoming accuracy≤±0.003mm) |

|

7 |

Press roll layout |

Vertical arrangement of two rollers |

|

8 |

Roll diameter of each guide roll of roller press |

≥φ120mm |

|

9 |

Precision of each guide metal roll of roller press |

Diameter: ≤± 0.1mm, roughness: ≤ 0.8 μ m. Circular runout: ≤ 0.04mm/m; |

|

10 |

Rubber roll accuracy of roller press |

Diameter: ≤± 0.2mm, cylindricity: ≤ 0.2mm, radial runout: ≤ 0.3mm/m; |

|

11 |

Roll diameter of each driving roll of roller press |

≥φ120mm |

|

12 |

Assembly accuracy between metal rolls of roller press |

Parallelism: ≤ 0.08mm, levelness: ≤ 0.06mm |

|

13 |

Assembly accuracy of rubber roll and metal roll of roller press |

Parallelism: ≤ 0.2mm, levelness: ≤ 0.1mm (the bearings used for each guide roll and drive roll of the roller press are Japanese NSK or Swedish SKF brand bearings) |

|

14 |

Safety protection function |

Mechanical interlocking and self-locking / safety warning signs / emergency stop switch buttons / protective covers, etc. signs shall be pasted at dangerous places and safety protection devices shall be installed |

|

15 |

Qualification rate of products produced by equipment |

≥99.5% |

|

16 |

Time rate |

>98% |

|

17 |

Rolling thickness CPK |

≥1.33 |

|

E.Configuration of main equipment components:

No. |

Name |

Brand |

1. |

Roll material |

Cr5; Sinosteel Xingtai roll Co., Ltd. and provide inspection report |

2. |

Roller bearing |

Wafangdian |

3. |

Roll motor / reducer |

Dongli, Guomao |

4. |

PLC |

Panasonic, Omron |

5. |

Touch screen |

Proface, Kunlun state |

6. |

Servo motor |

Mitsubishi, Huichuan |

7. |

Linear guide rail |

HIWIN |

8. |

Other bearings |

NSK |

9. |

Solenoid valve |

SMC、CKD |

10. |

Electrical components |

Schneider, Chint |

11. |

Electric proportional valve |

SMC、CKD |

12. |

Deviation correction control system |

Puliyuan, dongdeng |

13. |

Frequency converter |

Mitsubishi, Danfoss |

14. |

Main roll drive motor |

Dongli, Guomao |

15. |

sensor |

Omron、KEYENCE |

16. |

Coil diameter detection ultrasonic sensor |

Banner、Beijiafu |

17. |

Pneumatic components |

SMC、CKD |

18. |

Light sensor and displacement sensor |

Omron、KEYENCE |

19. |

Tension controller |

kortis |

20. |

Laser thickness gauge |

Dacheng, Shuangyuan |

21. |

Hydraulic system |

Vick hydraulic, Aili |

F.Equipment matching:

The pole strip continuous rolling production line is mainly composed of single station unwinding, edge cutting, dust removal device, oil pressure roller aligning machine, front and rear tension stretching device, laser online thickness measurement system, single station rewinding, electric control system, hydraulic system, suspension operation station, deviation correction device, electric control cabinet, etc.

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588