products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

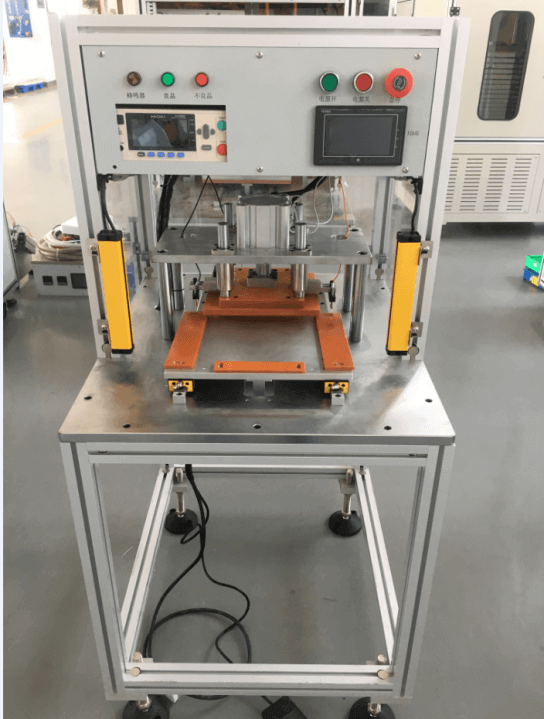

OCV Sorting and Testing Machine For Prismatic Battery Production

Model Number:

TMAX-YK-FXC-300Compliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Air Tightness Tester (Helium Detection)Next:

High Precision Lithium Battery Rolling Press Machine

OCV Sorting and Testing Machine For Prismatic Battery Production

1、 Equipment introduction

1. Equipment application

This equipment is designed to test the internal resistance and voltage of prismatic battery and conduct manual sorting after PLC automatically judges the sorting grade, and scan the code to read the capacity; Test the side voltage; Test the thickness of the electric core; And connect all data to MES system. The fixture is manually placed on the mobile fixture, and after the battery is placed, click the duplex control button with both hands, and the fixture will automatically move to the preloading position to complete the inspection process. Finally, it will be manually taken and manually operated in a reciprocating cycle, Continuous production can be realized (the test function includes code scanning and reading capacity; test voltage and internal resistance and record them in the QR code; test edge voltage to distinguish ng; secondary test OCV and software to distinguish; cell thickness measurement and upload to the corresponding bar code; all data are uploaded to the MES system).

2. Equipment structure

It is composed of manual operation platform / voltage testing mechanism / internal resistance testing mechanism / code scanning testing mechanism / side voltage testing mechanism / main control mechanism and other devices.

3. Equipment action process

Manually put the battery on the feeding test bench, and automatically enter the test station through the platform to test the voltage, internal resistance and code scanning; The thickness measuring mechanism presses down to measure the thickness; After the detection, the PLC sorts according to the preset sorting conditions and the indicator light is turned on. The edge voltage test needle interlocks to puncture the aluminum film and test the positive and negative electrode ears; Finally, manually classify the batteries according to the test data.

4. Software functions

1) Language: Simplified Chinese;

2) Scanning QR code reading capacity; Accurately read the voltage / internal resistance stored by the battery in the database.

Process editing and management functions:

3) Process editing and management functions:

a. Three parameter gear detection can be set, and different values can be selected according to the set gear;

b. The tested data files can be saved in the computer, and RS232C interface can be equipped for remote control and data acquisition and analysis.

2、Outline drawing of equipment (for reference)

2、Outline drawing of equipment (for reference)

3、Technical parameters of equipment

1. production efficiency: 2ppm;

2. Boundary dimension range of battery: L 80~300mm;W 50~200mm;T 2~18mm; It can be designed according to the size of the battery provided by the user;

3. Test mobility≥95%。The equipment operates for 8 hours, and the commissioning and maintenance time is less than 1%;

4. Product qualification rate 99%, The product qualification requirements are in accordance with the above requirements.

4、Technical parameters of instrument

1. Insulation resistance measurement range:100k~10TΩ;

2. Basic accuracy of insulation resistance:<1G: 1%,≥1G: 3%,≥10G: 5%,≥1T: 10%;

3. Output any negative voltage:1.0VDC~1000VDC,<100V:Voltage step 0.1V,≥100V:

4. Voltage step 1V,Basic accuracy:1%;

5. Thickness measurement accuracy: servo motor counterweight test, accuracy ±0.1mm

5、Main components of equipment

1. Cylinder:SMC/AirTAC;

2. Solenoid valve:SMC/AirTAC;

3. Temperature control meter: OMRON;

4. guide:HIWIN/KKT;

5. Linear bearing:MISUMI;

6. PLC:Mitsubishi / Panasonic;

7. Induction switch: Omron or kians;

8. Touch screen: display and control;

9. Servo: Panasonic

6、Installation environment requirements

1. Configure power supply:AC220V,50Hz, Voltage fluctuation range:+10%~-10%;

The total power of the equipment is about 3KW;

2. Compressed air: 0.25 ~ 0.76mpa; Air pressure fluctuation ± 1% (clean air after water removal, oil-free, filtration and pressure stabilization);

3. Equipment specification:

1) Equipment weight: About 450kg;

2) Overall dimension: about L (1.8m) * W (1.6m) * H (1.8m);

3) Appearance color: light gray or customer specified.

4. Environmental requirements:

1) Ambient temperature: 25 ± 5 ℃;

2) Relative humidity: 30% - 75% RCH, ensure that the air on site is dry and unblocked without acid-base corrosion;

3) Ground wire: protective grounding.

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588