products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

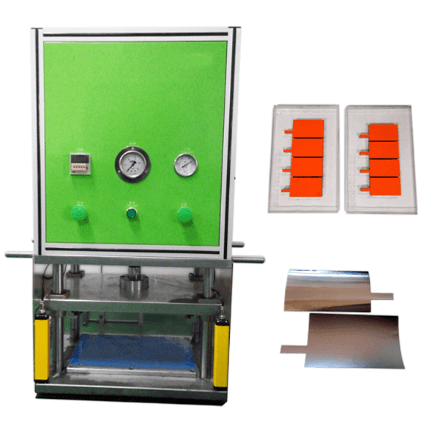

Pouch Cell Case Forming Machine for Aluminum-Laminated Films

Model Number:

TMAX-SCK200Net Weight:

120kgCompliance:

CE CertifiedWarranty:

1 yearMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Manual Aluminum-Laminated Film Pouch Case Punching Forming Machine for Pouch Cell Production

Pouch Cell Case/Cup Forming Machine for Aluminum-Laminated Films

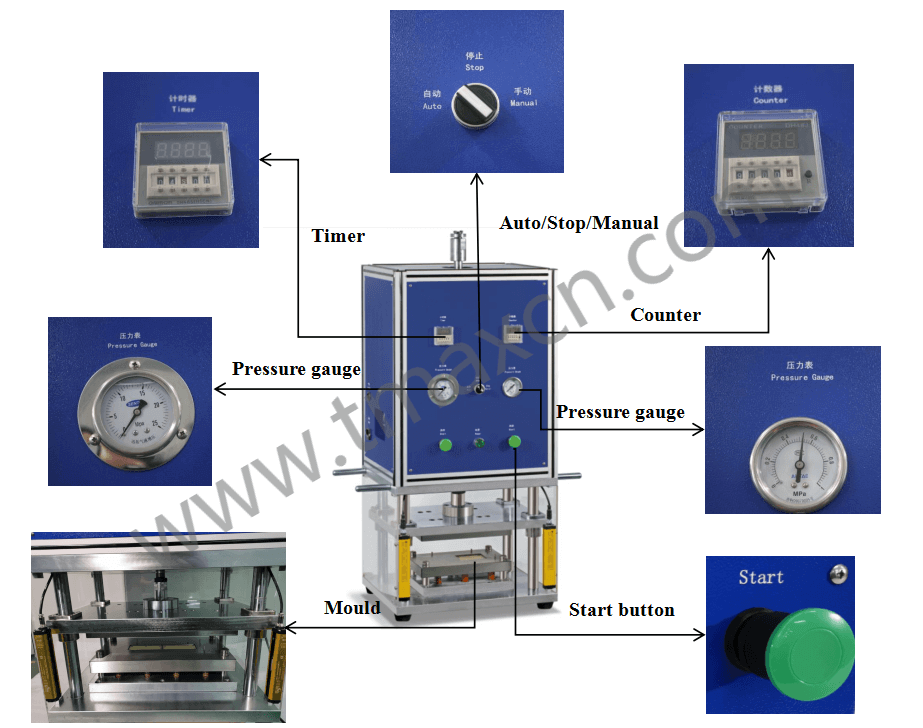

TMAX-SCK200 is a CE Certified pouch cell forming machine used in the production line of making pouch cell batteries with optional size range. It is used to prepare polymer cases made of Aluminum Laminated Films. To ensure continuity and compatibility for customer's research, adjustable depth (spacers is included in standard package) to directly match the electrodes cut by electrode cutting machine.

1 TMAX-SCK200 Battery Pouch Forming Machine is used for lithium polymer battery/ pouch cell cup forming in the of making pouch cell batteries.

2 The machine is used to prepare polymer cases made of Aluminum Laminated Films.

3 This lab aluminum laminated film pouch forming machine is designed with simple Spring mold with a customized size, which is more suitable for lab research.

If you need a bench top mini forming machine, please choose the TMAX-SCK100 model.

Model |

Lab Polymer Battery Pouch Forming Machine TMAX-SCK200 |

Source voltage |

AC 220V/110V, 50/60HZ |

Power |

100W |

Warranty |

Two years limited warranty with lifetime support |

Advantages |

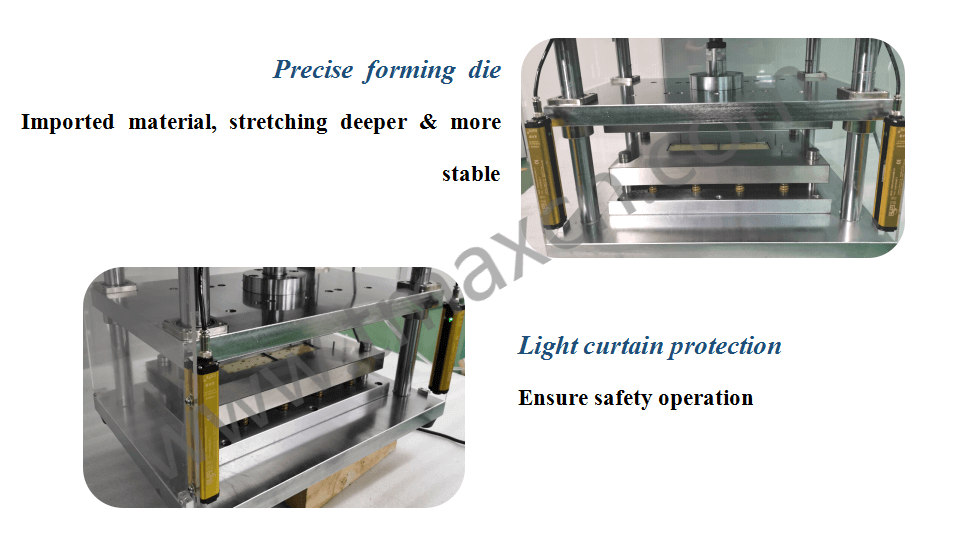

1 Structure of guide pin, slide up and down smoothly with high precision 2 Change mould, adjust tensile depth simply, quickly 3 Use screen and casing protection, guarantee safety 4 High strength of chrome steel and aluminum alloy, surface roasts the paint processing through environmental protection electroplating |

Suitable aluminum film thickness |

0.1-0.2mm |

Suitable mold size |

Customized as customer's request, with punching depth ≤24mm |

Max. Cup Depth |

Single pit punching depth ≤24mm |

Output |

200-400EA/H |

Output pressure |

5T |

Air source |

0.5-0.7MPa |

Mold materials |

SS136 Die steel |

Dimension (L*W*H) |

460*320*925mm |

Weight |

About 130kg |

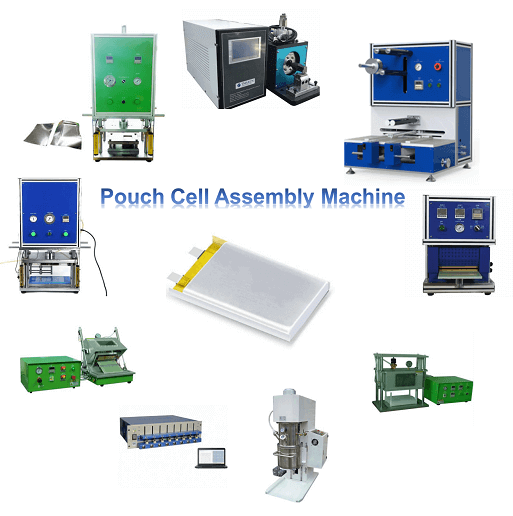

| Recommendation | For the pouch cell assembly, we also recommend you the following items: |

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588