products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Single Side Glove Box with Renewable Organic Solvent Adsorption System and Low Temperature Cold Trap

Model Number:

TMAX-Lab1500Compliance:

CE CertifiedWarranty:

One year limited warranty with lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Single Station Cleaning Glove Box without Oxygen Water Sensor and Purification SystemNext:

5C to 80C Cryogenic Cold Trap Low Temperature Cold Trap for Glovebox

Single Side Glove Box with Renewable Organic Solvent Adsorption System and Low Temperature Cold Trap

Images are for reference only(The actual picture is a single-sided three-station glove box rather than a single-sided two-station)

I. Acceptance criteria:

In the standard condition, that is, 20-25℃ constant temperature, relative humidity of 65%, 99.999% of the inert gas source, the empty box body circulating water oxygen indicators are reached less than 1ppm.

II. Main technical indicators and configuration

1. Box (front window can be lifted)

1.1 Size: 1500mm (L) × 900mm (H) × 750mm (W).

1.2 Material: stainless steel structure (Type 304), thickness 3mm.

1.3 Filter: pore size 0.3 micron.

1.4 Butyl rubber glove: imported from the U.S. thickness of 0.4mm, glove mouth 8 inches, hard aluminum alloy glove mouth (anti-corrosion treatment, anodized aluminum), caliber 220mm.

1.5 Window: tilted design of the operating surface, 8mm safety tempered glass front window, wear-resistant, corrosion-resistant, good light transmission, sealing ring using 3/8 inch thick OMEGA seal.

1.6. Use can maintain a certain positive and negative pressure (-10mbar-10mbar)

1.7. The box is equipped with anti-reflective lighting energy-saving lamps, soft light.

1.8 The box is equipped with a display board 2 shelves

1.9. The box is equipped with a multi-hole power terminal board (power supply: 220V ± 10% 50Hz ± 10%)

1.10. The box can be set up 4 standard KF-40 interface.

1.11. Leakage rate: ≤ 0.001vol%/h.

1.12. Steel structure bracket, including casters height 950 mm, installed with universal casters.

2. Transition Cabinet 1

2.1 Large and small transition cabinet(right side)

2.1.1 Shape: cylindrical (304 stainless steel), connected with the glove box, with a shaft-locked large transition cabinet door, easy to operate.

2.1.2 Size: diameter 360mm, 600mm long large transition cabinet, piston door, transition cabinet with a sliding tray, polished, the box is set up in another small transition cabinet, specifications: diameter 150mm, 300mm long, manual valve control pumping and replenishment.

2.1.3. tray: free to move the extension (used for large transition cabinet)

2.1.4 Vacuum degree ≤ 1bar (the large and small transition cabinets on the right are required to be vacuumed and displayed with a vacuum gauge)

3. Control system

3.1.1 Mode: including self-diagnosis, power failure and self-starting characteristics, with pressure control and self-adaptation function. Automatic control, cycle control, password protection, vacuum chamber control using LCD display. Unit control adopts Siemens PLC touch screen.

3.2. Pressure control: control the pressure of the box and transition chamber at a certain set value.

a) Users can set any working pressure interval between +12.5 and -12.5 mbar, and PLC will automatically regulate the box pressure within the set range. The default value of the working pressure interval is -1 to +3 mbar.

b) When the box pressure is greater than 12 mbar, the PLC automatically opens the safety valve to relieve pressure and protect gloves, equipment and materials inside the box.

c) Use the foot switch to fine tune the box pressure.

3.3. Foot pedal: can control the pressure of the glove box, easy to operate.

4. Circulation system (including purification and regeneration system)

4.1. Germany BASF, the United States UOP purification materials, Germany Baode valve. Host system integrated modular design, fully automatic electronically controlled gas solenoid valve group, PLC control, circuits, circulating pumps, purification of the residence, the display is integrated into an independent purifier, constituting a compact, simple system.

4.2. Control: water, oxygen control in less than 1PPm

4.3. Adjustment device: through the PLC touch regulation (heating, evacuation, purification, regeneration) in addition to the whole process of 2.5 hours of ventilation without human monitoring.

4.4. Working gas: He.N2/ or Ar gas (gas cycle)

4.5. Circulation fan: 0-100m³ high-speed frequency conversion fan, microprocessor control, after the pressure test stainless steel device.

4.6 Purification column: single purification column, imported purification material Germany BASF deoxidizing material 5kg, American UOP high efficient water absorbing material 5kg, very high life span degree, ensure the user in the use of the product in the process of purification of the product ability to long lasting. In addition to the water capacity of 2.2㎏ oxygen absorption capacity of 63L.

4.7 Purification valve: full-automatic electropneumatic valve.

4.8 Filter: It adopts the high efficiency filter with 0.3 micron aperture in accordance with the HEPA standard.

4.9 Regeneration: used to purify the system again, so that the activation; regeneration needs helium / H2, nitrogen / H2 or argon / H2 gas mixture, of which H2 accounted for 10%. Regenerated gas into the flow meter and then into the purification column.

5. Display system

Germany SIEMENS, unit control adopts Siemens PLC touch screen. English and Chinese bilingual can be switched.

6. Water analyzer, (imported from abroad) brand material: Britain MICHELL / (in accordance with the customer's use of environmental decisions)

Non-domestic or domestic assembly, third-party data to ensure credibility.

1) Measuring range: 0-1000ppm

2) Accuracy: ±1% ppm

3) Display: The output of the analyzer is connected to the PLC, the detection value is displayed on the touch screen, and the alarm value can be set.

4) Control: The gas circulation system can be controlled according to the user's setting to realize the circulation drop.

5) Environment: -10 ℃ -50 ℃

7. Oxygen analyzer, (imported from abroad) Brand Material: U.S. AVCRAY (in accordance with the customer's use of environmental decisions)

Non-domestic or domestic assembly, third-party data to ensure credibility.

1) Measurement range can be set: 0-1000, ppm

2)Environment: -10℃-50

3)Accuracy: ±1% ppm

4)Installation position: Oxygen sensor is installed on the box, regardless of gas circulation or not, the oxygen sensor uninterruptedly detects the atmosphere inside the box and displays the oxygen content inside the glove box.

5)Sensor: electrochemical material battery, its advantages are accurate zero point, small drift, avoid other battery material is easy to be corroded; low replacement cost (only replace the oxygen battery).

6) Display: The output of the analyzer is connected to PLC, the detected value is displayed on the touch screen, and the alarm value can be set.

Control: The user can select the automatic cycle function to maintain the oxygen content in the glove box within the user's specified range.

8. Vacuum system

Increase the start-stop time control of vacuum pump. The vacuum pump is British Edwards vacuum pump, model RV12, flow rate 12m3/h, ultimate vacuum 2x10-3 mbar. It can vacuum the transition chamber separately and realize separate control at any time. (Imported from abroad)

9. Box automatic cleaning

Automatic gas control plating plate; box gas automatic cleaning function users set the cleaning time, and then touch the start button on the touch screen, the system will begin to clean the box, to the set time is automatically stopped.

10. Organic solvent adsorption system (renewable)

In order to prevent the impact of organic solvents on the purification column, a solvent column in series to the glove box system, the medium is mainly high-quality and efficient activated carbon and prevent the formation of hydrofluoric acid activated alumina. Organic solvent adsorption system filling capacity of 7KG

Renewable solvent adsorption system, through the PLC touch regulation (heating, evacuation, purification, regeneration) and other processes.

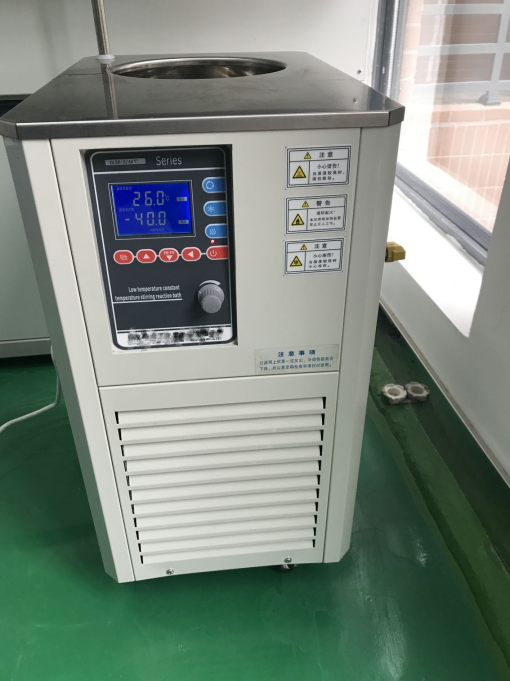

11. 5℃--80℃ low-temperature cold bath pot

Basic parameters

Cavity volume: 4.7 liters, size: φ200*150mm

Temperature control range:+0℃~-80℃

Display: plc integrated display temperature

Internal material: 304 stainless steel, brushed surface

External material: 1.5mm stainless steel plate, plastic spraying

Cooling method: cold bath pot periphery evenly arranged copper tubes, copper tubes into the coolant

Refrigeration mode: imported compressor

Refrigerant: R404 R23

Temperature control range: +5 ℃ ~ -80 ℃

Temperature fluctuation:±0.1℃

Cooling capacity: 275-3150W

Heating power: 800W

Cooling power: 2840W

Circulation power: 100W

Circulation pump flow: 25L/min

Installation: embedded in the bottom or side of the glove box

Product features

Original hermetic compressor of international famous manufacturer, with advanced performance and reliable quality;

Refrigeration unit professional relays, protectors, capacitors, etc. are imported original high-quality equipment to ensure reliability and service life;

Digital display temperature control, simple and eye-catching operation;

Circulation system is made of stainless steel, with anti-corrosion, anti-rust, anti-temperature liquid pollution;

12. Equipment working conditions: (provided by the user)

1.0. Power supply: two-phase three-wire AC220V, power ≥ 4.5Kw;

1.1. laboratory to have an independent ground: <3Ω, from the equipment to the ground connection is recommended to use ≥ 10mm2 flat copper wire;

1.2. water supply: no;

1.3. Relative humidity: <75%;

1.4. Indoor no large amount of dust, no corrosive, flammable and explosive gases;

1.5. Equipment footprint: length × width: 2500mm × 1200mm

III. Main configurations

No. |

Configuration |

Unit |

Amount |

Manufacturer/Brand |

Remarks |

1 |

Box |

Piece |

1 |

TMAXCN |

304 Stainless Steel Thickness 3mm |

2 |

Transition cabinet |

Set |

1 |

TMAXCN |

304 stainless steel |

3 |

Control system |

Set |

1 |

Germany SIEMENS Omron electronics, etc. |

Imported assembled |

4 |

Circulation system (including purification and regeneration system) |

Set |

1 |

Germany BASF, the United States UOP purification materials, Germany Bauder valve |

Imported assembled |

5 |

Display system |

Set |

1 |

Germany SIEMENS |

Import |

6 |

Gloves |

Piece |

3 |

USA |

Import |

7 |

Pipe connections |

Set |

1 |

France Legris |

Import |

8 |

Pressure gauges |

Set |

1 |

WIka, Germany |

Import |

9 |

PLC Water Analyzer |

Piece |

1 |

Michell, UK |

Import |

10 |

PLC Oxygen Analyzer |

Piece |

1 |

AVCRAY, USA |

Import |

11 |

Vacuum pumps |

Piece |

1 |

RV12 |

Import |

12 |

Organic solvent adsorption |

Set |

1 |

TMAXCN |

304 stainless steel |

13 |

Low Temperature Cold Well |

Set |

1 |

Century Iowa |

Outsourcing remodeling |

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588