products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

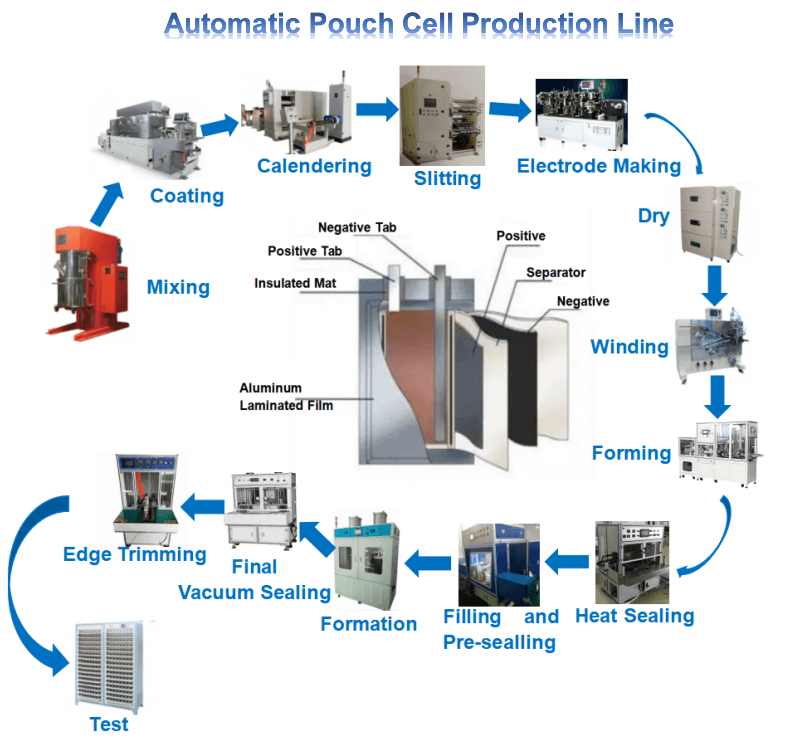

Automatic Pouch Cell Dual-Station Top and Side Hot Sealing Machine

Model Number:

TMAX-2DCF-550ACompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Pouch Cell Six-Station Top and Side Hot Sealing MachineNext:

Automatic Linear 4-in-1 Top & Side Hot Sealing Machine Heat Sealer for Pouch Cell

Automatic Pouch Cell Dual-Station Top and Side Hot Sealing Machine

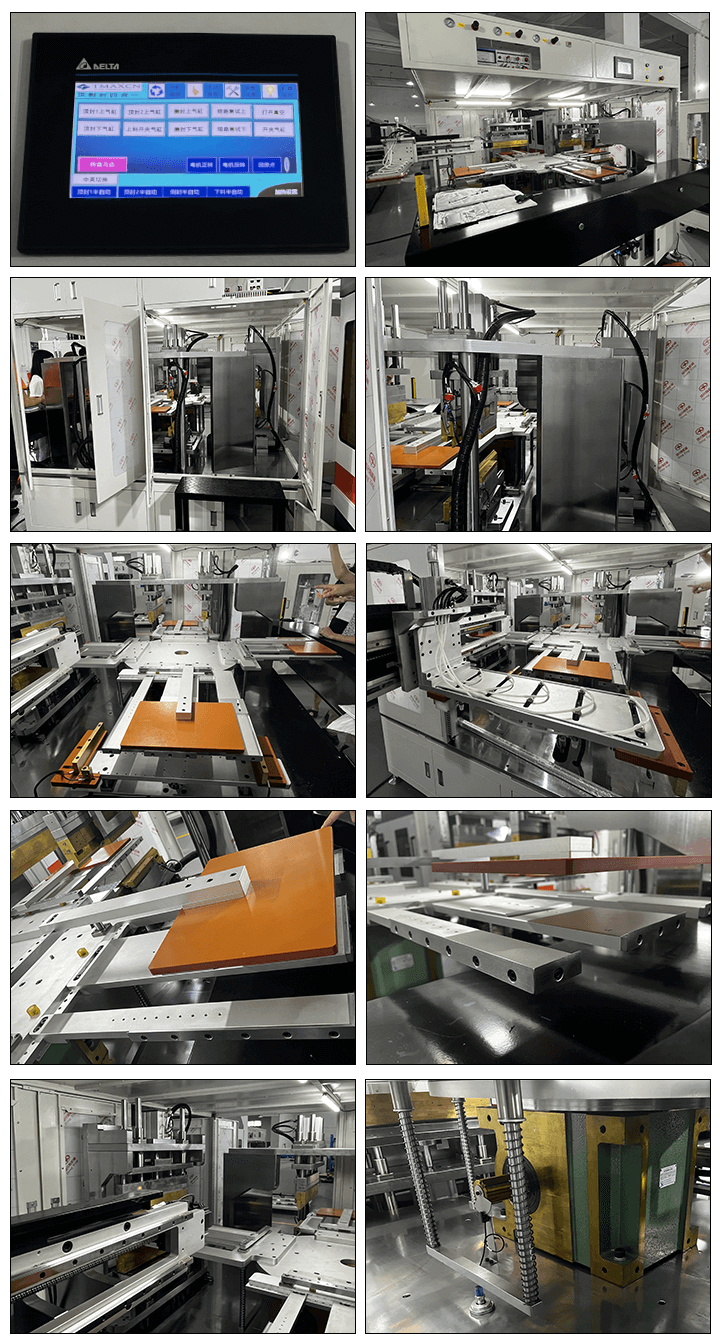

1. Equipment Description

This equipment is suitable for top and side heat sealing of pouch-type lithium-ion batteries. (Top sealing uses soft sealing; side sealing uses hard sealing, depending on customer requirements.)

2. Basic Configuration

l Tray fixtures

l Heat sealing heads

l Safety light curtains

l The machine body adopts aluminum profile frame with safety covers.

l Electrical control system

l Pneumatic components: Taiwan Airtac

l Temperature controller: Beiermei

l Buttons: Shanghai Ergong brand

l Touch screen: Weinview

l Safety light curtain: Fotek

l Machine body: surface pickling treatment, default baked white paint

l Mechanical parts material: aluminum and steel

l Safety cover: sheet metal parts + acrylic panels

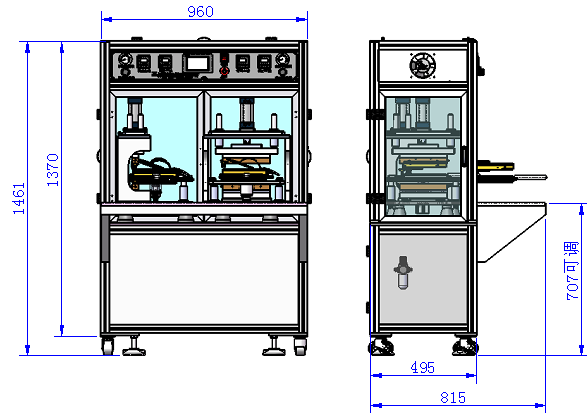

3. Basic Parameters

Parameter |

Specification |

Machine Cycle Time |

7 pcs/s |

Sealing Width |

Customized (Standard: 4 mm) |

Applicable Battery Size |

550 × 450 mm (including airbag) |

Machine Capacity |

4–6 pcs/min |

Manual Adjustment |

Available |

Power Supply |

220V/AC/50Hz, Single Phase |

Air Pressure |

0.5–0.6 MPa |

Equipment Weight |

400 kg |

Machine Dimensions |

1400 mm (L) × 1200 mm (W) × 1400 mm (H) |

Top/Side Sealing Cylinder |

∮63 × 50 |

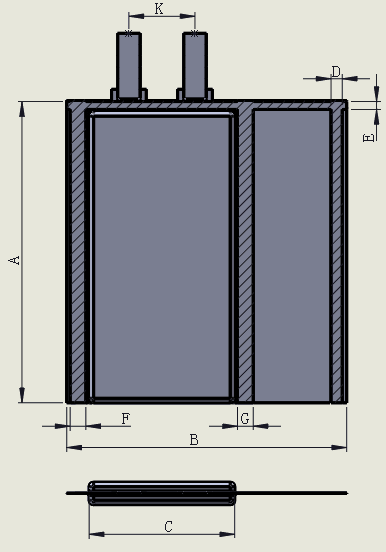

4. Process Parameters

A |

B |

C |

D |

E |

F |

G |

K |

|

|

|

|

|

|

|

|

5. Appearance Layout

6. Product Photos

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com +86 18659217588

+86 18659217588