products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

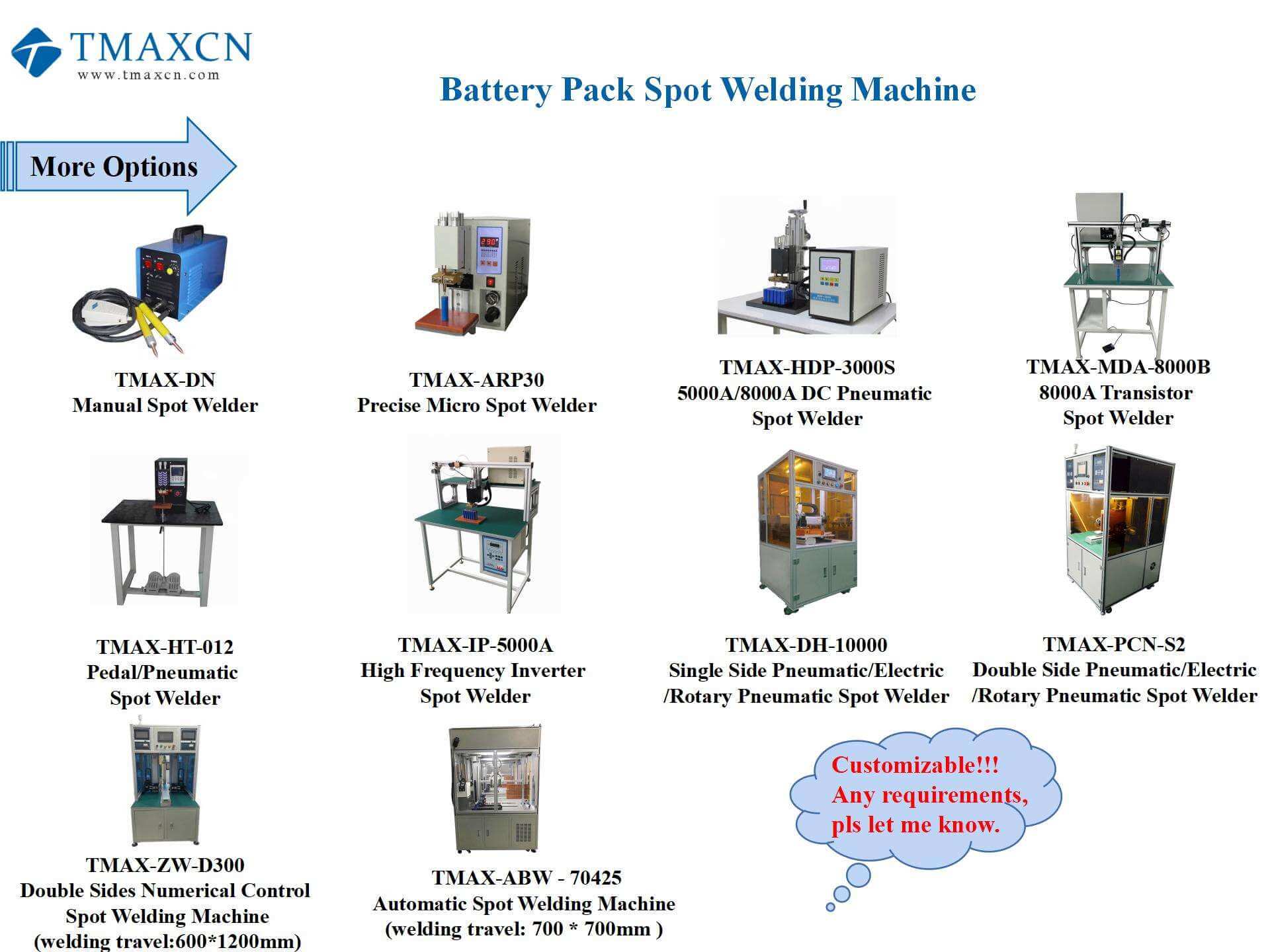

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Single Side EV Bike Battery Making Automatic Spot Welding Machine

Model Number:

TMAX-SP-02Type:

AutomaticDimension(L*W*H):

900*900*1650mmNet Weight:

200kgCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportPlace of Origin:

ChinaUpdate:

OptionalShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lithium-ion Cylindrical Battery Pack Assembling LineNext:

100V 200A Finished Battery Pack Comprehensive Tester

Single Side EV Bike Battery Making Automatic Spot Welding Machine

Application:

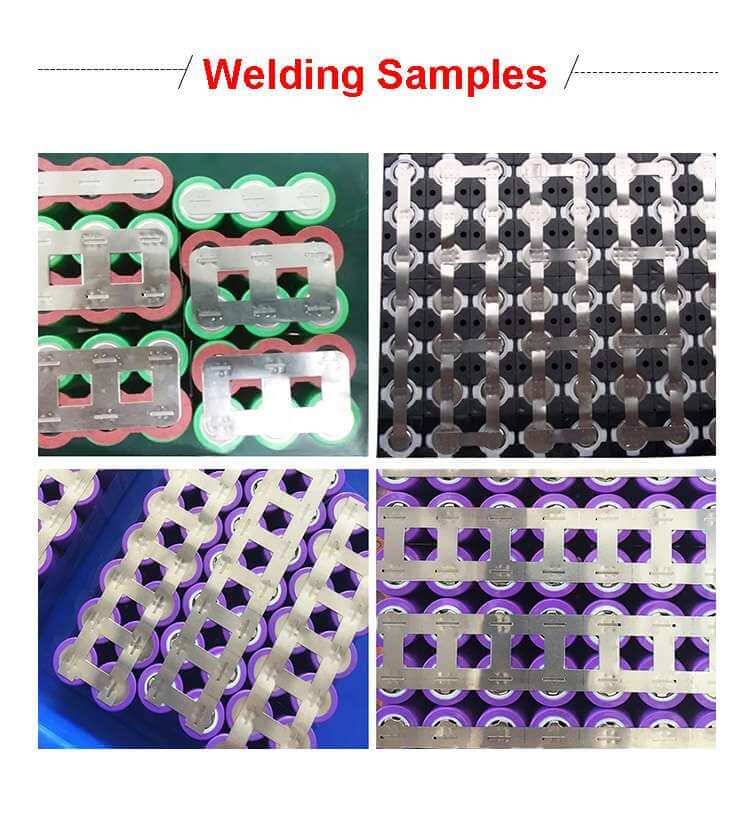

Photovoltaic, power battery, NiMH lithium battery and other batteries are connected with nickel alloy strip, aluminum nickel composite strip, wire and guide strip, household electrical parts and guide strip, hardware accessories, copper and silver products, stainless steel peripheral connection, bulb foot welding, electronic parts, all kinds of high and low conductive metal welding, etc.

Feature:

1) Induct the load voltage, control the voltage in the feedback mode, and realize high-quality welding.

2) Power on mode of pre heat and main heat: preheat before welding to ensure stable welding quality.

3) Keep the continuity of energy density, short welding time, reduce the deformation and discoloration of base metal. (the welding time is controlled in microseconds, and the mode of continuous output)

4) Easy to change from low current to high current, suitable for precision welding.

5) The upper and lower limits of current can be set to judge whether the welding quality is good or not, which is suitable for the welding automation platform.

6) The welding current will rise with the power on time to ensure the welding effect.

7) Stable control system

8) High configuration regulating device

9) High precision working procedure

10) High cost performance of products

Performance features:

1. Touch screen display, more convenient operation and clearer display

2. Three file programming modes, manual input, array, CAD drawing import, simple and fast response to various complex program editing

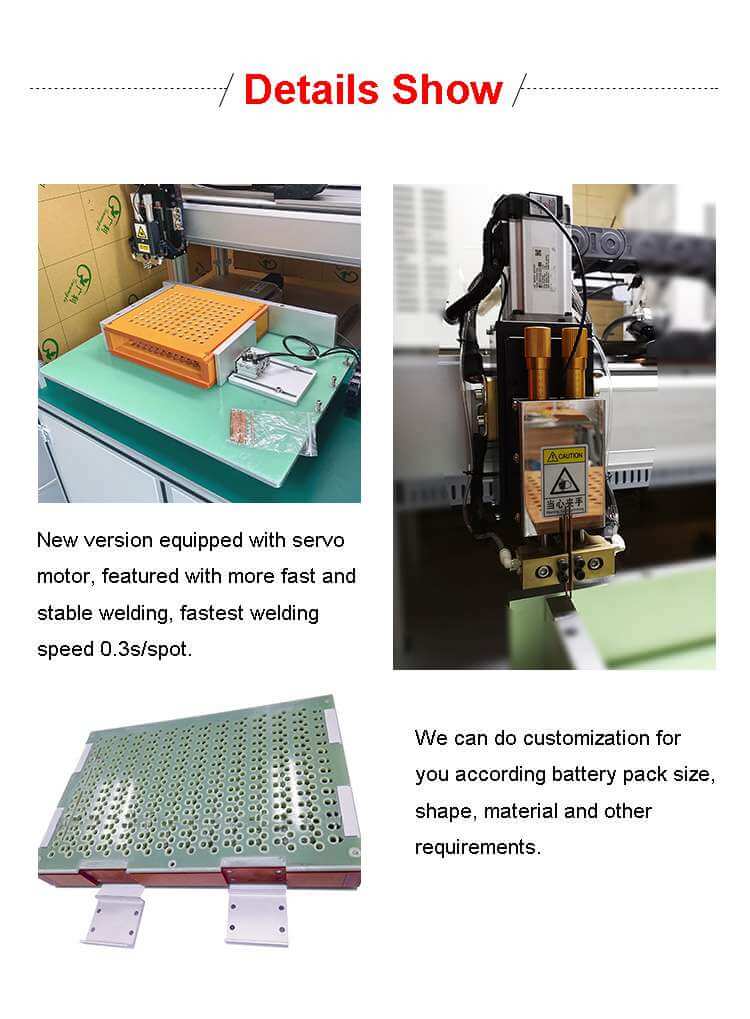

3. The welding head has the function of air cooling or water cooling, which can effectively reduce the influence of spot welding needle temperature on welding quality

4. It can store up to 99 groups of files, which is easy to call and does not need complicated process of line changing and machine adjusting

5. The spot welding program of a side and B side of fixture can be switched.

Specification

Power Supply |

AC 220V±10% 50Hz |

Electric Current |

DC |

Welding Mode |

Inverter DC |

Welding Current |

5000A or 8000A optional |

Power Form |

Automatic |

Y-axis Travel |

400mm (can be customized) |

X-axis Travel |

500mm (can be customized) |

Spot Welding Speed |

0.35s/point; 2800pcs / hour |

Fast Speed of Motor Drive |

1000mm/s |

Number of Cores Loaded |

X direction: 26 Y direction: 26 (standard:18650 cell) |

Number of file groups that can be stored |

99 group |

Operating System |

Embedded system + man machine interface |

Transmission mode |

Stepping + imported precision linear guide rail, optional servo + screw rod) |

Equipment air pressure |

0.4-0.7Mpa |

Weight |

200kg |

Size |

900*900*1650mm |

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588