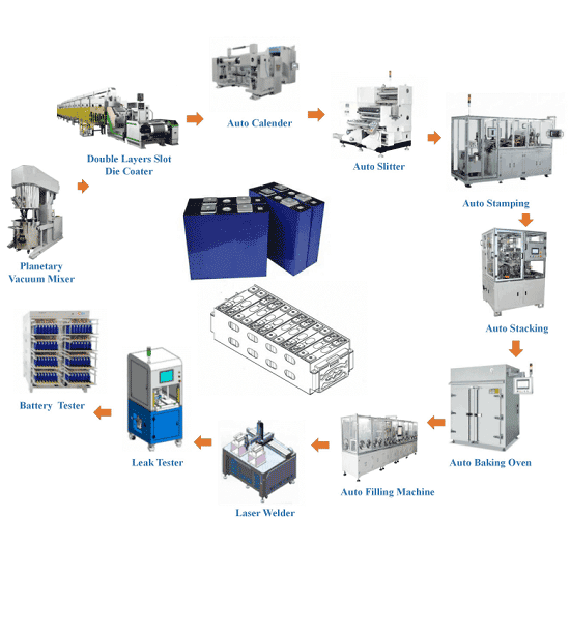

Turnkey sulotion, EV Car battery, Prismatic cell production line

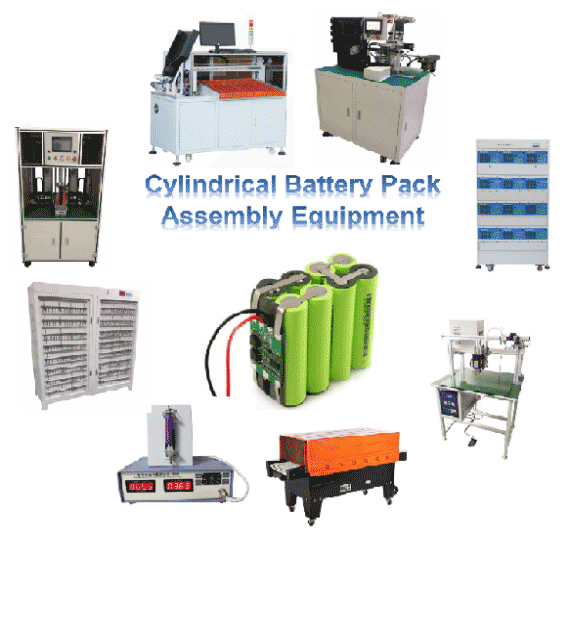

18650, 4680, 21700, 14500 Battery produciton Line

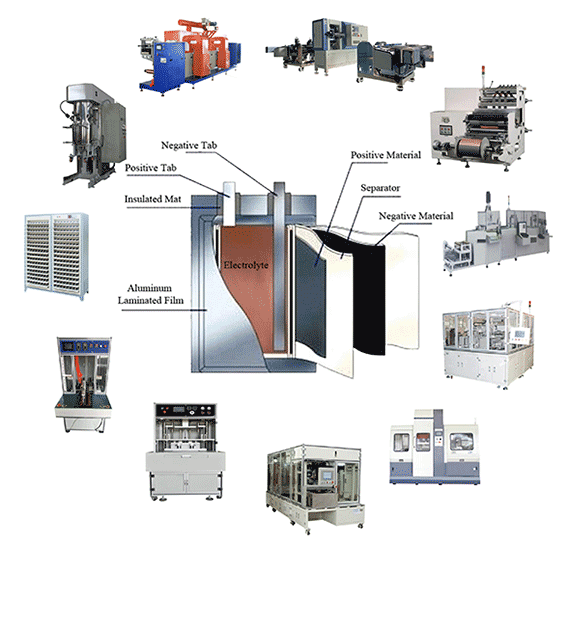

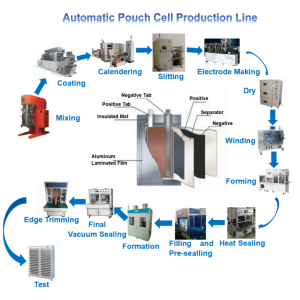

Turnkey solution, Pouch Cell manufacturing line

Battery Pack Assembly Machine

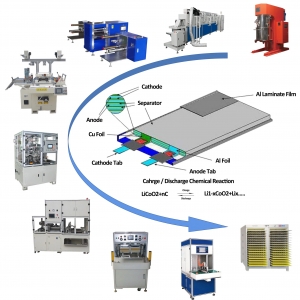

Pouch Cell Assembly Machine

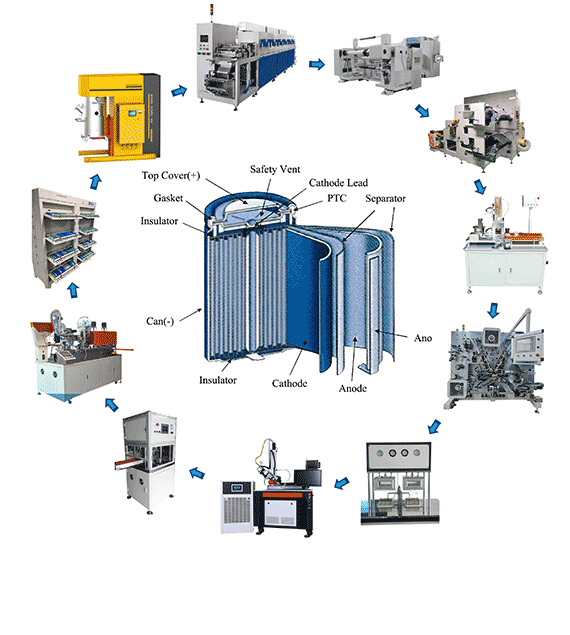

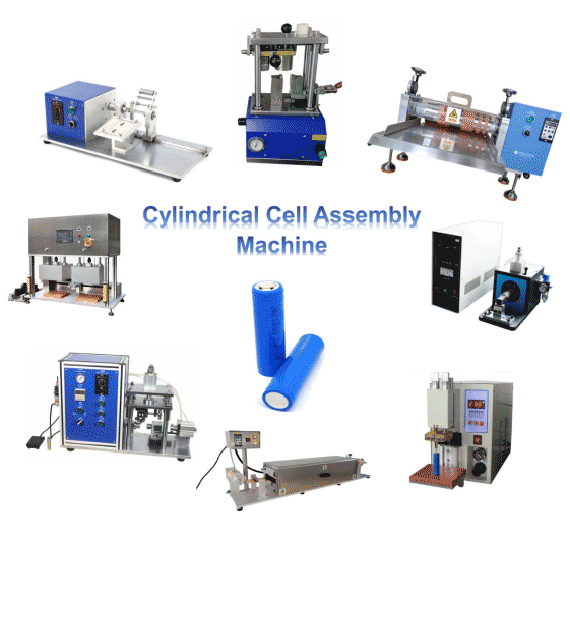

Cylindrical Cell Assembly Machine

Turnkey Solution, Lithium Battery Materials

More than 20 years professional and experienced exporting team

Just For Professional Battery Equipments

Our service team reflects TMAX pledge to provide its customers with the most comprehensive technical support, we will provide a range of services for overall lab solutions as the one-stop certification, such as lab design, lab planning, lab ren...

TMAX's professional sales teams can help our customers to solve the problem in one-stop. With more than 20 years experience in research and development, now we have different manufacturing departments and sales teams for battery lab equipment We have...

Xiamen Tmax Battery Equipments Limited. is professionally engaged in production and R&D of various battery lab equipment. We have the capacity in researching and developing new products and have our own engineering R&D institute. Our equipmen...

2024-04-09

TMAX recently participated in the exhibition "Autonomous power sources 2024", the main exhibition on chemical power sources in the Russian Federation....

2024-01-19

The successful shipment of Swedish battery production line marks the arrival of the era of sodium batteries Date:January 19, 2024 In January 2024...

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with lithium battery equipments, technology, etc. We have total manufacturing facilities of around 200000 square foot and more than 230 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable pr... Read more