products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

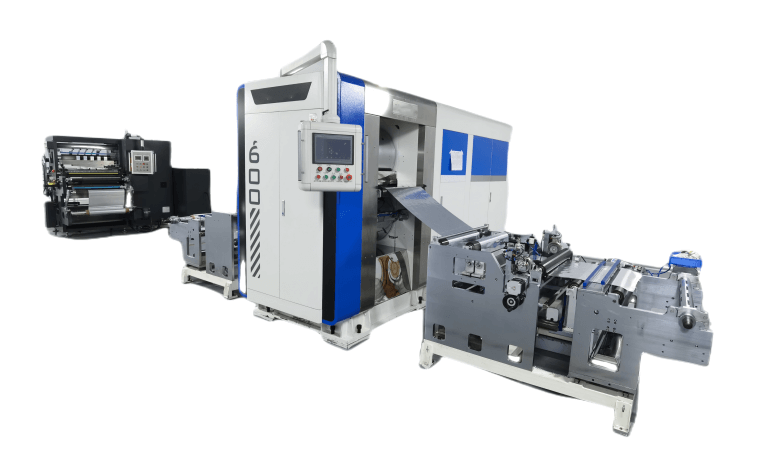

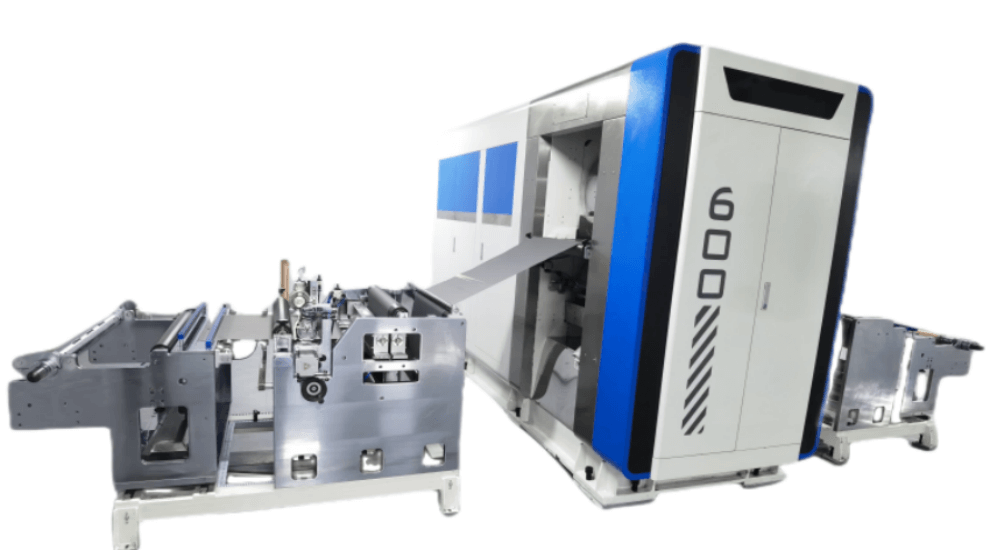

Roll to Roll Calender Machine with Edge Cutting for Battery Production Line

Model Number:

TMAX-YJ-Dia600*700WType:

AutomaticInput Power:

23KWDimension(L*W*H):

L3300mm*W1080mm*H2100mm,Net Weight:

17TCompliance:

CE CertifiedWarranty:

1 yearShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

60 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

X-RAY Testing Machine for Internal Defect DetectionNext:

1GWh EV Car Battery LFP/NMC/LTO 30Ah 50Ah 100Ah 200Ah Prismatic Cell Aluminium Case Cell Production Line

Dia600*700mm W Calender Machine with Heating Function for Battery Production Line

1. Equipment function:

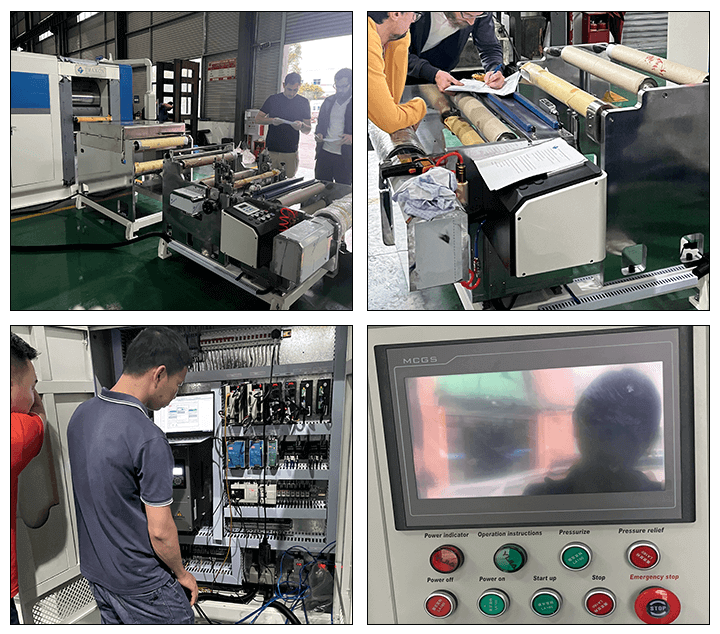

1) The machine is integrally cast with 45 # steel frame, large slider structure, large bearing capacity, small deformation, large rolling force and high rolling speed;

2) It adopts constant pressure and limited gap pressing mode, and can continuously press the battery electrode coated intermittently. The pressure is stable, the roller cylindricity is high, the rolling piece is uniform, and the deformation is small. Greatly improve production efficiency and reduce personnel workload;

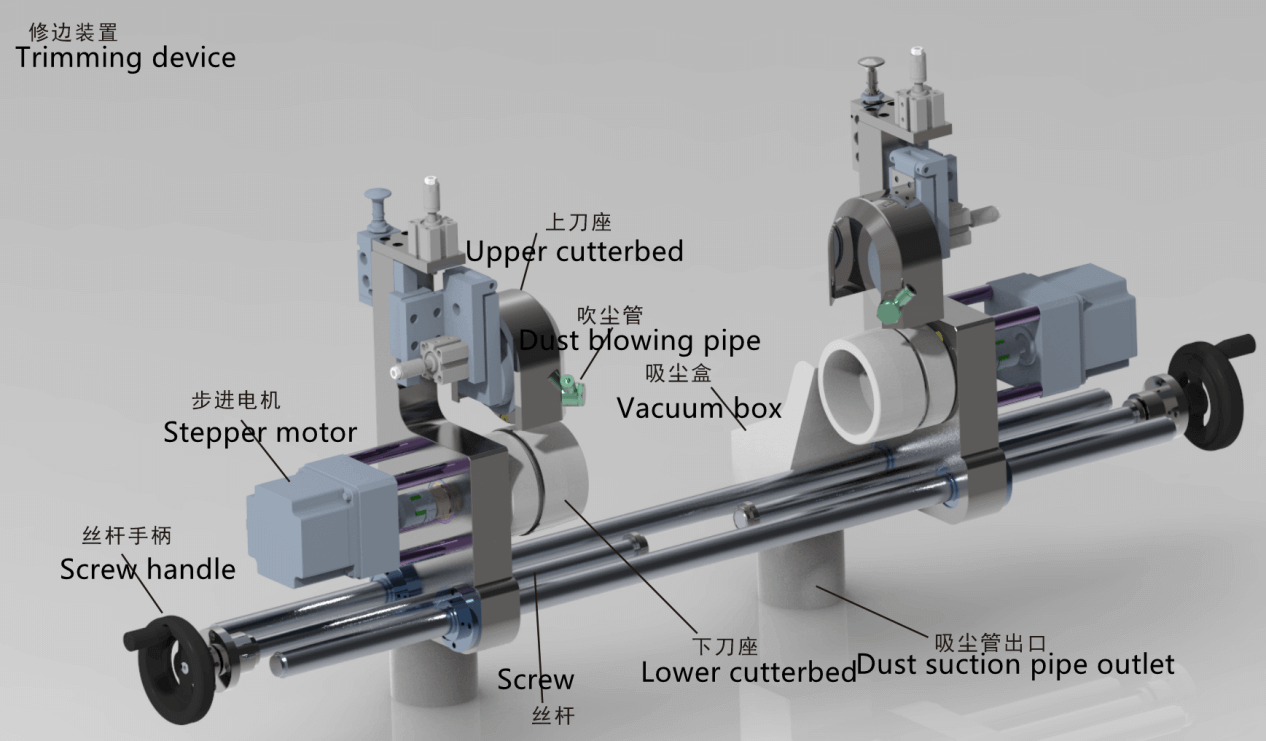

3) It has the functions of edge cutting, dust-proof device and blade brushing;

4) It has the function of roller surface cleaning mechanism;

5) It has a platform for deviation correction tension control unwinding and tape splicing;

6) With deviation correction tension control winding;

7) The pole piece buffer device is provided;

8) With roll removal device;

9) The electric pump pressurization system controls the lifting of the oil cylinder through the man-machine interface touch screen to drive the lifting of the roller;

10) Constant pressure automatic control, through man-machine interface adjustment to change the roll oil pressure;

11) The roll movement value is displayed on the human-computer interface screen;

12) The man-machine interface input adjustment changes the gap between the rolls of the hydraulic roll aligning machine.

2. Working mode:

Tension unwinding → deviation correction → tape receiving platform → trimming dedusting (dust suction) → pole piece buffering → tension separation → rolling (upper and lower rolls with knife) → pole piece buffering → deviation correction → tension winding

3. Equipment specification:

1) Roller size: Dia 600mm* W700mm;

2) Rolling speed: 2 -12r/min, infinitely variable;

3) Rolling linear speed: 2-22m/min

4) Maximum working pressure: 500KN-6000KN;

5) Power supply requirements: 380V/50Hz, power: 23KW;

6) Compressed air: pressure 0.5Mpa~0.7Mpa, flow: 0.04M3/min

7) Total weight of equipment: about 17T,

Load bearing requirement of equipment installation ground:>2.5T/m2, and place base plate at the bottom of equipment.

8) Equipment size: about 3300 mm L* W 1080mm * 2100mm H,

Overall size of production line: about 7000mm L * 3300mm W * 2100mm H

4. Equipment performance index:

1. |

Maximum rolling force:6000KN(600T); |

2. |

Roll surface finish: surface roughness is 0.02 μ M (approximate mirror surface); |

3. |

Roll heat treatment: roll hardness: HRC66-68, roll tempering: HB280-300, quenching depth ≥ 20MM, Roll cylindricity ≤ ± 0.001 mm |

4. |

The roll bearing adopts p5 high precision bearing; |

5. |

Roll gap adjustment: automatic locking device, adjustable from 0 to 2mm; |

6. |

Rolling mode: adopt continuous rolling mode and gap rollig mode. Pre pressure is applied maximum pre pressure of hydraulic pressure application method: 6000KN, using oil pressure constant pressure and gap limiting working method type. Oil pressure is generated by means of electric pump pressurization; Gap adjustment range: 0-2mm. |

7. |

Roll drive mode: the upper and lower rolls of the universal coupling are driven separately, and the electrode are coated continuously during rolling or in the gap to run smoothly without impact or creeping; |

8. |

Electric oil pressure system is adopted for oil pressure power; |

9. |

The edge cutting tool is an assembled structure, and the brush blade device is convenient for threading. The width of the edge cutting tool is adjustable, and it is suitable for 350~650mm edge parting; |

10. |

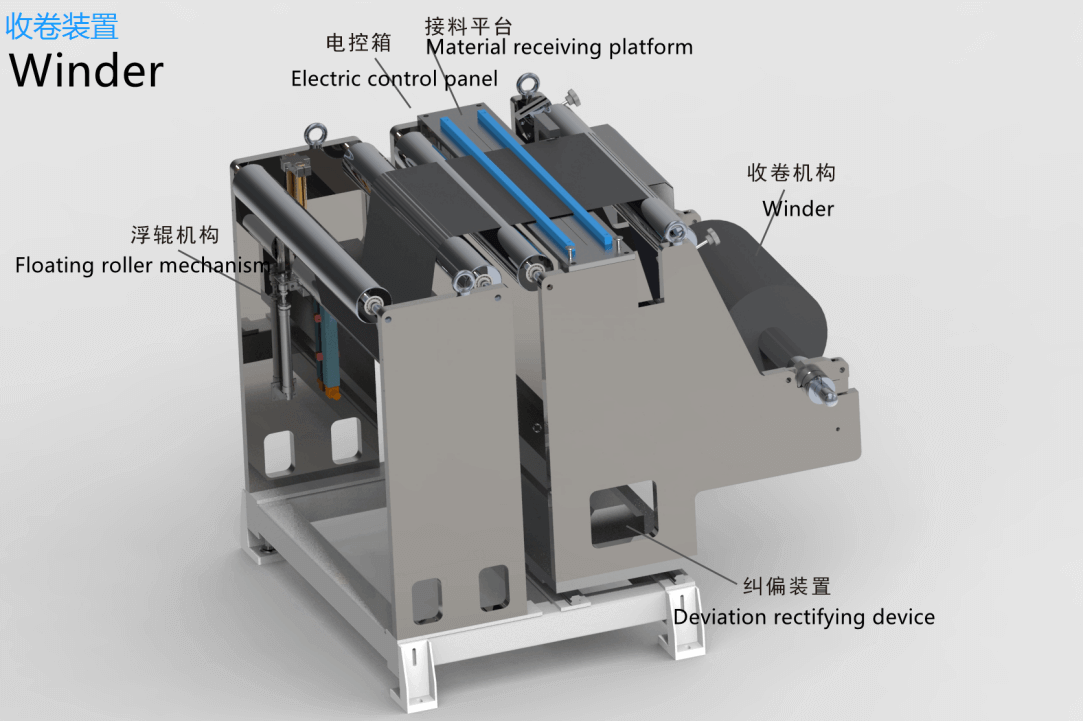

Performance index of winder and winder: a: Electrode: The cylinder core is Dia 76 mm, The maximum winding straight diameter is Dia 450 mm Max width of electrode:700 mm b: Unwinding parameters: the control accuracy of electrode tension during unwinding is 5% Tension adjustment (setting) range 0.5~3.5Kgf c: Edge control: deviation correction accuracy ≤± 0.5mm d: Tension adjustment: 25N. |

5. Configuration of main parts of equipment:

Item |

Remark |

1. Rolling material |

9Cr3Mo |

2. Wallboard material |

45# |

3. Machine enclosure |

Cold rolled sheet, more than 1.5mm |

4. Inflatable shaft |

45# Steel, 3 inches |

5. Winding and unwinding frame |

45# Steel |

6. Roller |

oxygen aluminum alloy roll is used |

Standard main components |

|

1) Touch screen |

MCGS |

2) Servo driver |

Fuji |

3) Analog output module |

Mitsubishi, Japan |

4) Liquid pressure sensor |

TPT505 |

5) Roll frequency converter |

Hipmont |

6) PLC |

Mitsubishi, Japan |

7) Hydraulic booster system |

Rongfeng |

8) Reducer |

XLED95-121-11KW |

9) Winding and unwinding correction |

Dongdeng |

10)Dongdeng |

Dongdeng |

11) Tension control system |

France Kortis |

12) Bearing |

P5 high precision roller bearing |

13) Edge parting tool |

imported tungsten steel blade |

6.Equipment matching:

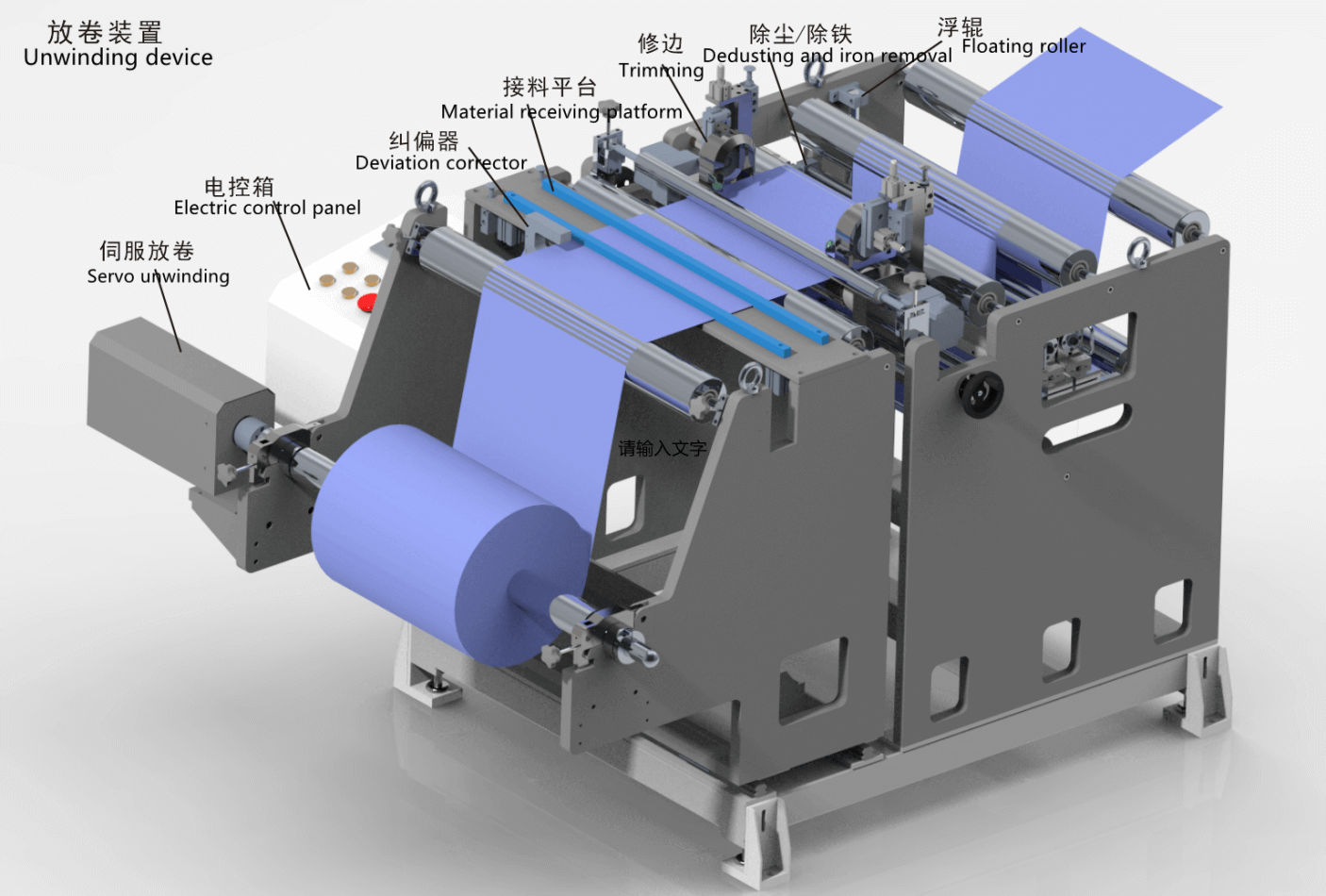

The electrode continuous rolling production line is mainly composed of unwinder, trimming deduster, oil pressure roller counter, winder, electric control system, electric booster pump, deviation correction device, etc.

1. Unwinder:

2.Trimming dust remover:

3.Winder:

![]()

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588