products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

1200°C Dual Zones CVD Tube Furnace with Mass Flow Control System & Vacuum System

Model Number:

TMAX-1200double CVDCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

1200C Single Temperature Zone CVD Furnace with Five Channels Gas Mixed SystemNext:

1200℃ Dual Zones Sliding CVD Furnace

1200°C Dual Zones CVD Tube Furnace with Mass Flow Control System & Vacuum System

It is competent for the experiments as CVD, Diffusion and other thermo-treatments under vacuum status and shielding gas protection.The furnace comes with a 2-channel digital LED display mas flow gas control station.

1. Tube furnace

Detailed technical parameters

Model |

TL1200-1200-I |

TL1200-1200-II |

TL1200-1200-III |

TL1200-1200-IV |

Power |

3.6KW |

3.6KW |

3.6KW |

5.2KW |

Tube size(OD)(mm) |

Dia60(OD)X1000mm |

Dia80(OD)X1000mm |

Dia100(OD)X1000mm |

Dia150(OD)X1000mm |

Dimensions |

1140X460X695 |

1140X460X695 |

1140X460X695 |

1110X530X647 |

Supply voltage |

220V |

|||

Phase |

single phase |

|||

Heating element |

Resistance wire imported

from Sweden Kanthal A1 (resistance wire guaranteed for 2 years) |

|||

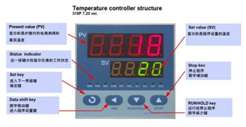

Temperature control |

UAV program temperature

control instrument (standard)

1, 30-stage program

temperature control intelligent PID adjustment.

2.Withover-temperatureprotection,theelectricfurnaceheatingcircuitisautomaticallycutoffwhenthetemperatureis over-temperature or broken, (when the

electric furnace temperature exceeds 1200 degrees or the thermocouple is

blown, the AC relay on the main circuit will be automatically disconnected,

the main circuit is broken. On, the ON light on the panel is off, the OFF

light is on, and the limited protection electricfurnace). 3, with 485 communication interface (standard when purchasing software)

4, with power-off protection function, that is, when the power is turned on after the power is turned off, the program does not start from the starting temperature, but the furnace temperature rises from the time of power failure.

5, the meter has the function of temperature self-tuning

|

|||

Furnace material |

1. High-quality

high-purity alumina polycrystalline fiber curing furnace formed by vacuum

suctionfiltration.

2. Formed by

Japanesetechnology.

3. The spacing and

pitch of the resistance wires in the furnace are all arranged according to

the best thermal technology in Japan, and the temperature field is simulated

by the thermalsoftware. |

Valve and flange

|

|

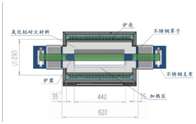

60/80/100 top view |

|

Control accuracy |

+/- 1 ℃ |

Trigger |

Phase-shifted trigger |

Electric appliance |

Zhejiang

chint |

Silicon controlled |

106/16E

Simenkang, Germany |

The highest temperature in the first and second temperature

zones |

1200

℃ |

Rated temperature in

the first andsecond temperaturezones |

1100 ℃ |

Length of heating section in the first temperaturezone |

205mm |

Length of heating section in the second temperature zone |

205mm |

Length of

constant temperature section in the first temperature |

80mm |

zone |

|

Length of constant

temperature section in the second temperature

zone |

80mm |

Heating rate |

≤30 ℃/ Min (it can be modified as required) |

Temperature field curve |

|

Recommended

rate of temperature

rise |

≤15 ℃/ Min |

Thermocouple Type |

K

Type |

Constant temperature length |

150mm |

Peripheral

surface temperature |

≤45℃ |

Open cover protection system |

When

the furnace cover is opened, the relay will automatically cut off the main

power supply, effectively ensuring the safety

of the user |

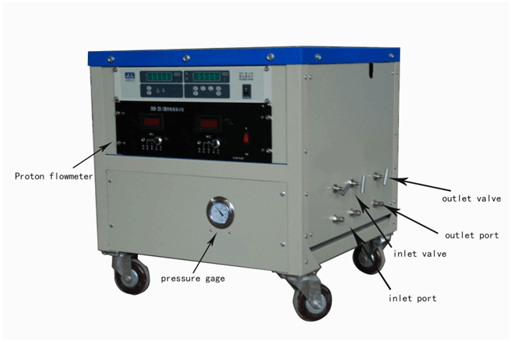

2. Gas supply system

Introduction to gas supply system:

(1) Components of the (mixed) gas system:

a) Float flow

meter or proton flow meter

b) Pressure

gauge

c) Cut-off

valve

d) Interface

board

e) Valve

connector

f) Cylinder

connector

g) Teflon

tube (connecting pipe for gas supply or mixed system station and gas cylinder

connection pipe )

h) Mixed gas

tank

i) Stainless

steel pipe (connecting pipe for gas supply or mixed control system station)

j) Cover

Main technical data

No |

Item |

D08-2E |

1 |

Output

Power |

+15V±5%

300mA -15V±5%

600mA |

2 |

Reference

Source |

+5.00V±0.1%

5mA |

3 |

Power

Supply |

~220V/~110±10%

50/60Hz |

4 |

Maximum

Power |

25W |

5 |

Input

and Output Signal |

0~+5V |

6 |

Dimension |

Standard

Dimension :(440X100X220)mm Maximum

Dimension :(440X114X278)mm |

7 |

Weight |

4.2Kg |

8 |

Control

Channel Figure and Display Feature |

2

Channel of MFC/MFM and 2 Display Monitor |

3. Vacuum System

The system (can pump the vacuum in the tube furnace to

0.6Pa) consists of a suction flange (self-made) with KF25 interface, high

vacuum baffle method, resistance vacuum gauge, bellows, bracket (homemade),

vacuum pump Connect the tee pipe at the flange outlet, connect the resistance

silicon to one end of the three-way pipe, connect the high vacuum flapper valve

to the other end, connect the flapper valve and the vacuum pump with the

corrugation of Dia25, and use the KF25 quick clamp for the connection port.

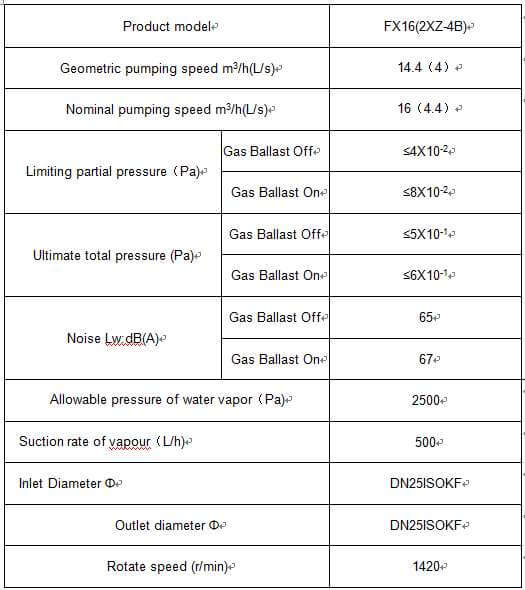

Technical Parameters:

* Distribution regulation: ZJ-52T resistance gauge

* Measuring range: 10 5 ~10 -1 Pa

* Number of measurements: 1 way

* Number of control channels: 2 roads can be extended

to 4 or 8 roads

* Control range: 5 × 10 3 ~ 5 × 10 -1 Pa

* Control mode: relay contact output, load capacity

AC220V/3A (or DC28V/3A) non-inductive load

* Power: 90-260V/50Hz or 220V ± 10% 50Hz

* Power consumption: 25W

* Weight: 4Kg/3Kg/0.5Kg (depending on the chassis)

* Chassis size: 240 × 88 × 280 or 265 × 119 × 280 or

96 × 96 × 120

480 × 88 × 280 or 480 × 119 × 280 (width × height ×

depth)

Performance characteristics:

*LED green screen digital display.

* Wide range of star surveys

* Fast response speed

* Microcomputer correction regulates nonlinearity and

reduces measurement errors.

* Optical isolation, digital filtering, enhanced

anti-interference ability.

* PVC color panel, beautiful appearance.

* Point control or area relay control output, while

the set point has power-down protection memory function.

Adopt FX-16 vacuum pump

Standard Package

Part

description |

Quantity |

Part image |

TMAX-2-1200-C split tube furnace |

1 set |

|

Multi-channel

gas supply system |

1 set |

|

Vacuum

pump and enclosure (optional) |

1 set |

|

Quartz

tube |

1 pc |

|

Analog

flow meter |

1 pc |

|

Stainless

steel vacuum sealing flanges w/ pressure meter |

1 set |

|

Stainless

steel hook |

1 pc |

|

Alumina

ceramic thermal block |

2 pairs |

|

Thermal

gloves |

1 pair |

|

High

temperature Al2O3 alumina crucible |

5 pcs |

|

Spare

fuse |

2 pcs |

|

USB/RS485 computer

interface kit |

1 set |

|

English▼

English▼

.jpg)

.jpg)

.jpg)

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com