products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

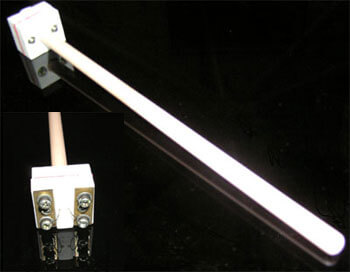

1500°C Max Tube Furnace (50mm OD) with Sliding Flanges for Fast Heating/Cooling

Model Number:

TMAX-1500X-RTP50Dimension(L*W*H):

Size can be customizedCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

1000°C Max Slideable RTP (4'' OD) Tube Furnace with Rapidly Heating & CoolingNext:

UL Standard Compact RTP Furnace with 4" ID Quartz Tube & Digital Vacuum Gauge up to 1100ºC

1500°C Max Tube Furnace (50mm OD) with Sliding Flanges for Fast Heating/Cooling

SPECIFICATIONS

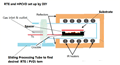

Furnace structure |

One sliding flange is installed on right side furnace, which can move processing tube in & out easily. Vacuum flanges can reach 10E-5 torr by molecular pump or 10E-3 torr by a mechanical pump. The flange has a 1/4"Dia, the thermal couple built in for monitoring real-time temperature inside the tube. Digital vacuum gauge is installed the flange RS485 port included for computerized control |

Power |

2.5KW ( 20A breaker required) |

Voltage |

AC 208-240V Single Phase, 50/60 Hz |

Max. temperature |

1500℃ |

Continuous temperature |

1400 ℃ |

Temperature accuracy |

+/ - 1℃ |

Heating zone length |

6" (152 mm) |

Constant temperature zone |

100 mm (+/-1oC) @ 800 - 1500℃ |

Heating elements |

SiC rod (1500C grade) , 4 pcs |

|

Two S type thermal couples are included. One S type 5" Length is built in furnace to control furnace temperature And another S type 14" inserted inside tube to monitor sample real temperature profile (below right)

|

|

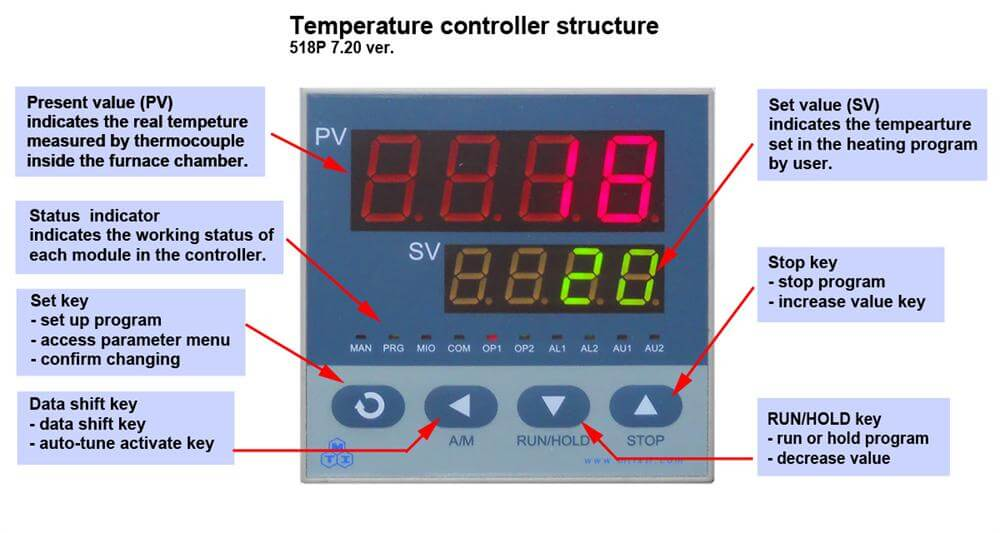

Temperature controllers |

|

Two digital temperature controllers with 30 programmable segments are built in. One control furnace temperature and another monitor temperature of the sample inside processing tube. Built-in over temperature alarm and protection allows for operation without an attendant. +/- 1 ºC temperature accuracy. |

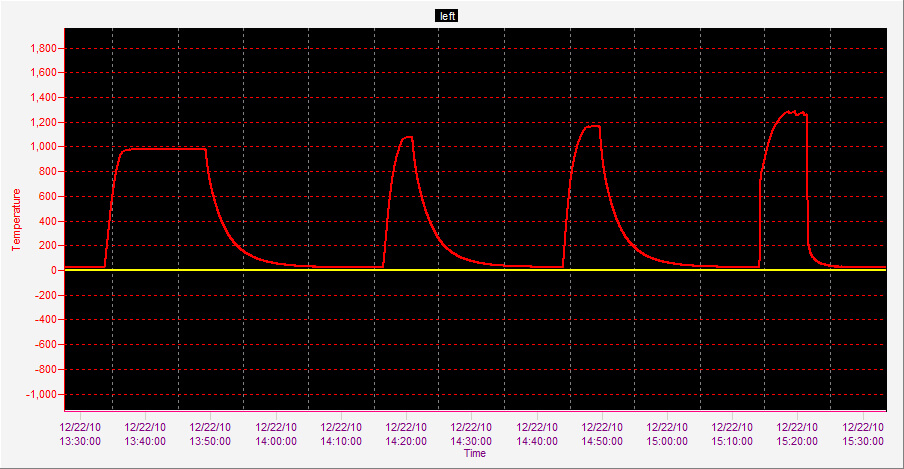

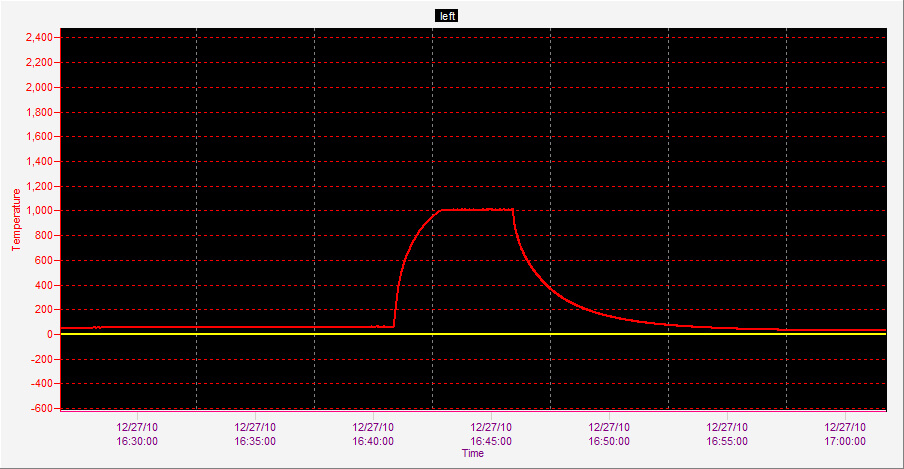

Heating & cooling rate |

For Mullite Tube: Heating speed: 10℃/sec (RT - 800°C); 7℃/sec (800°C - 1000°C); 4℃/sec (1000°C - 1100°C); 3℃/sec (1100°C - 1200°C); 1.5℃/sec (1200°C - 1300°C); 0.7℃/sec (1300°C - 1350°C)

Cooling speed: 14℃/sec (1350°C - 1000°C); 7℃/sec (1000°C - 800°C); 5℃/sec (800°C - 600°C); 3.76℃/sec (600°C - 500°C); 2.5℃/sec (500°C - 400°C); 1.36℃/sec (400°C - 300°C)

For Quartz Tube: Heating speed: 30℃/sec (RT - 500°C); 12℃/sec (500°C - 800°C); 5℃/sec (800°C - 900°C); 3.6℃/sec (900°C - 1000°C); 1℃/sec (1000°C - 1100°C);

16℃/sec (1100°C - 800°C); 9℃/sec (800°C - 600°C); 5℃/sec (600°C - 500°C); 3.6℃/sec (500°C - 400°C); 2.5℃/sec (400°C - 300°C); |

Processing tube size |

Oneend Closed mullite tube made in the USA Size: OD: 50mm x ID 44mm x 304.8mm L Max. Temp. 1300oC in vacuum

One end closed quartz tube Size: OD: 50mm x ID 44mm x 304.8mm L Max. Temp. 1000oC in vacuum

Warning: Processing tube is consumable and easy to broken during RTP, not covered by warranty. Pls click pic above to order spare |

Sliding flange |

· Double sliding rail made by Cr-plated steel · Sliding length: 350 mm |

Vacuum seal & digital vacuum gauge |

One stainless steel flanges with 1/4"Dia fitting for insect thermal couple is included One digital vacuum gauge and valves are included for immediate use. OPTIONAL: A gas-type independent (above 10mbar) digital vacuum gauge with a wide range between 3.8x10-5 to 1125 Torr. Aside from greater measurement precision, this gauge reduces risks of chamber explosions caused by the incorrect reading of gas pressures due to gas-type dependency. |

Vacuum level |

Limited by the pump. ( pump is not included ) 10E-5 torr can be reached by molecular pump 10E-2 torr by a mechanical pump.

|

Dimensions |

400L x 305W x 530H mm (15.7" x 12" x 21") |

Net weight |

~ 45 Kg |

Shipping package size |

47"x31"x40" |

Shipping weight |

150 lbs |

Warranty |

One year limited manufacturer's warranty with lifetime support (Consumable parts such as furnace liner, processing tubes, heating elements, and O-rings are not covered by the warranty, please order replacements at related products below.) |

Laptop, software & wifi control (optional) |

Brand new laptop with Microsoft Window 10 and Microsoft Office 2013 (30 days free trial) for immediate use. Labview Based Temperature Control System enables user to edit temperature profile, manage heat-treatment recipe, record and plot data for MTI furnaces. A wireless remote control provides up to 300 meters operating range. Above features are available upon request at an extra cost (up to $1,000). Please contact us for more information. Note: The software is only compatible with MTI’s Yudian Temperature Controller |

|

CE Certified UL / MET / CSA Certification is available upon request, additional charges will apply Temperature controller is MET and CE Certified Transformer is UL Certified |

Warning:

|

To get the fast heating performance, first keep the tube out of the chamber meanwhile, preheat the chamber to the required temperature. Then insert the tube into the chamber to get fast heat. Please watch the demo video below to see how this is done. The tube furnaces with processing tube are designed for using under vacuum and low pressure < 0.02 MPa / 0.2 Bar/3 PSI. Vacuum limit definition for all mullite tube furnaces: Vacuum pressures may only be safely used up to 1300°C Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation.

Never heat the furnace while the gas release valve is closed and a positive pressure condition exists within the furnace chamber. The pressure gauge must be used to closely monitor the chamber condition at all times during the heating process; please open the gas release valve immediately once the chamber pressure has reached over 3 PSI to prevent unforeseeable damages. The flow rate for gasses should be limited to < 200 SCCM ( or 200ml/min ) NOTE The mullite tube shall be considered as a consumable part. We strongly recommend user keep spare tubes in order to ensure the continuity of operation. The tube is not covered by Warranty. Use the link to order more. Please wear protective gears, such as heat resistant suit & gloves, if you intend to retract the tube from the heating chamber. DO NOT TOUCH THE TUBE SURFACE WHEN IT IS HOT! |

Application note |

You may modify the RTP furnace into a small RTE (rapid thermal evaporation ) or HPCV ( hybrid physical & chemical vapor deposition ) by DIY.

|

Attention notes |

Performance degradation (i.e. furnace can not reach the maximum temperature 1500°C or it is drawing a higher than normal working current) can be expected due to the use of aged SiC heating elements. It is necessary to replace all the heating elements if the above symptoms were seen. |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com