products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

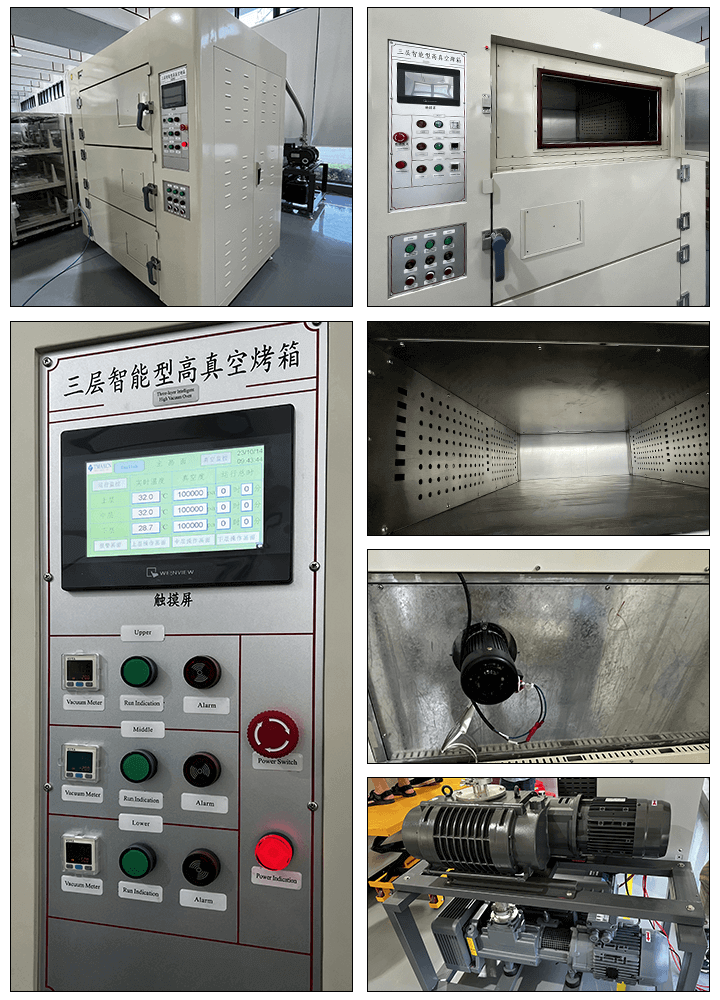

150C Vertical Two Chambers Vacuum Drying Oven for Battery Electrode or Battery Core

Model Number:

TMAX-JK-ZKHX-A2Input Power:

6KW(peak power)×2Dimension(L*W*H):

H1800mm×W1200mm×H1100mmMax. Loading Capacity:

H600mm×W600mm×H750mm×2 layersCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Hydraulic Electric Roll to Roll Press Machine for High-precision Rolling of Battery ElectrodeNext:

Pneumatic Cylindrical Battery Sealing Machine (Optional Die 18650, 21700 or 26650. 32650, 32700, etc.)

150C Vertical Two Chambers Vacuum Drying Oven for Battery Electrode or Battery Core

I、 Introduction:

Vacuum Drying Oven is suitable for the vacuum baking process of battery electrode piece and battery cell to be injected in the production process of lithium battery. It adopts the industry-leading uniform temperature technology, the temperature fluctuation is ± 2 ℃; the vacuum cavity can be kept at - 0.098 MPa for more than 12 hours; multiple quality and safety protection are the ideal equipment to ensure the drying effect.

II、 Features:

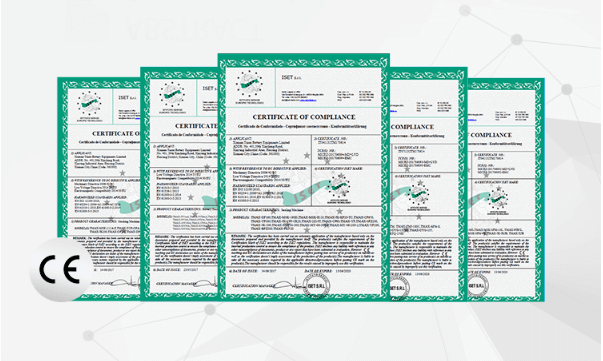

A. Electrical features:

1. AISET three position PID temperature controller is selected for temperature control with high resolution.

2. The temperature measuring probe is specially made by Taiwan Valin, which is placed at the back of vacuum chamber to quickly and truly reflect the working temperature.

3. Triple over temperature protection device can cut off heating automatically when the temperature exceeds the set value to ensure the safety of materials and equipment.

4. Equipped with timing shutdown function, timing starts after constant temperature, automatically stops when baking time ends, and each layer can be timed independently.

5. The fan of each layer can be opened independently and can be used as cooling fan when heating is stopped.

6. Using high quality sus stainless steel seamless electric heating tube, heating up quickly, energy saving and durable.

B. Structural features:

1. The vacuum chamber is heated by hot air around the chamber, and the design of circulating air duct is innovated to ensure high-precision uniform temperature in the chamber.

2. The inner chamber is made of T3.0 mm high quality sus stainless steel, which is resistant to corrosion of battery slurry and electrolyte.

3. The multi-layer heat insulation material forms a closed insulation layer, which can block the heat loss and effectively solve the problems of adjacent warehouse temperature and external wall heating.

4. The door is double-layer toughened glass structure with over-voltage protection function. When the air pressure in the chamber is too high, it can automatically deflate, so that the air pressure in the chamber can be restored to the allowable range.

5. The vacuum chamber is equipped with a silicone sealing ring between the chamber and the door, and the chamber can be kept at - 0.098 MPa for more than 12 hours.

Specifications

Item |

Specification |

Touch Screen |

7.0 Inch Xinjie color touch screen |

PLC |

Programmable controller |

Thermostat |

Shanghai Yatai brand PID temperature controller |

vacuum meter |

Panasonic digital vacuum meter |

Operation interface |

Color touch screen + PID temperature controller + digital vacuum meter; automatic air change, constant temperature and cooling can be realized |

Working chamber size |

H600mm×W600mm×H750mm×2 layers Optional Size:H650mm×W650mm×H750mm×2 layers

|

Whole machine size |

H1800mm×W1200mm×H1100mm Optional Size:H1900mm×W1250mm×H1100mm

|

Power |

Single layer:6KW(peak power)×2 |

Power supply |

three-phase,380V /480V |

Supporting gas source |

vacuum:-0.095~-0.1Mpa compressed air:0.4~0.5Mpa Dry gas:0.1~0.2Mpa |

Working temperature |

Room temperature~150℃ |

Temp Accuracy |

±1℃ |

Heating rate |

It takes about 35 minutes for room temperature (25 ℃) to rise to 80 ℃ |

Heating mode |

Electric heating, each layer of oven increases independent internal heat circulation, each layer is independent |

Over temperature protection device |

Each layer is equipped with double machinery overtemperature protection and independent temperature measurement |

Alarm mode |

Alarm lamp + buzzer on |

Vacuum degree of working room |

0~-0.098Mpa,After holding pressure for 12 hours, the vacuum degree shall be kept at least 96% |

Pressure change rate |

The vacuum breaking time of the working room is less than 1 minute |

Working chamber material |

SUS 304 stainless steel |

Machine material |

SECC steel plate with plastic coating on the surface |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com