products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

1600ºC Max. Two Zone Rotary Tube Furnace with 60 mm OD Alumina Tube -- GSL-1600X-R60-II

Model Number:

GSL-1600X-R60-IIInput Power:

8 KWNet Weight:

100KgCompliance:

CE CertifiedWarranty:

One year limited warranty with lifetime supportShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

1400C Split Tube Furnace with Optional 1.6 - 4" Tube & 10" Long Heating ZoneNext:

Laboratory Dual Heating Zone 1100C Split Tube Furnace with Optional Tube (Dia 50, 85 mm) & Flange

1600ºC Max. Two Zone Rotary Tube Furnace with 60 mm OD Alumina Tube -- GSL-1600X-R60-II

Specifications:

Furnace

Construction |

1.

Double shell casing with three cooling fans. 2.

High purity Alumina fibrous insulation for max. energy saving. 3.

Dual heating zone with 1600ºC max. continuous working

temperature |

Heating Zone length |

1. Two zones

heated separately Zone

1: working temperature 800 - 1600ºC (heated by

MoSi2 ), Zone 2:

working temperatur 800 - 1600 2. Cnstant

temperature zone length: 10" (250mm) within +/-1 3. Max.

Heating rate: 10 |

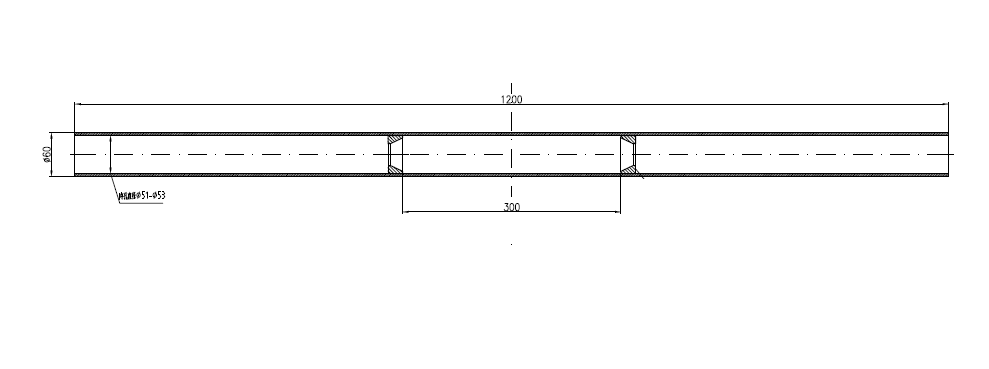

Processing tube &

Sealing Flange |

1. 99.8%

purity Alumina Tube 2. 60

mmstainless steel vacuum sealing flange with valve and meter is included 3. One ceramic

block is installed on each side flange to blcok thermal radiation during

rotation 4. 2-3/8"

(60mm) O.D. x 2-1/8" (54mm) I.D x 40" (1000 mm) Length with

inside block (see picture below )

|

Gas Fittings |

Inlet Fitting: Elbow Push-in connector for 6mm O.D tube; Outlet Fitting: Elbow Push-in connector for 12mm O.D tube

|

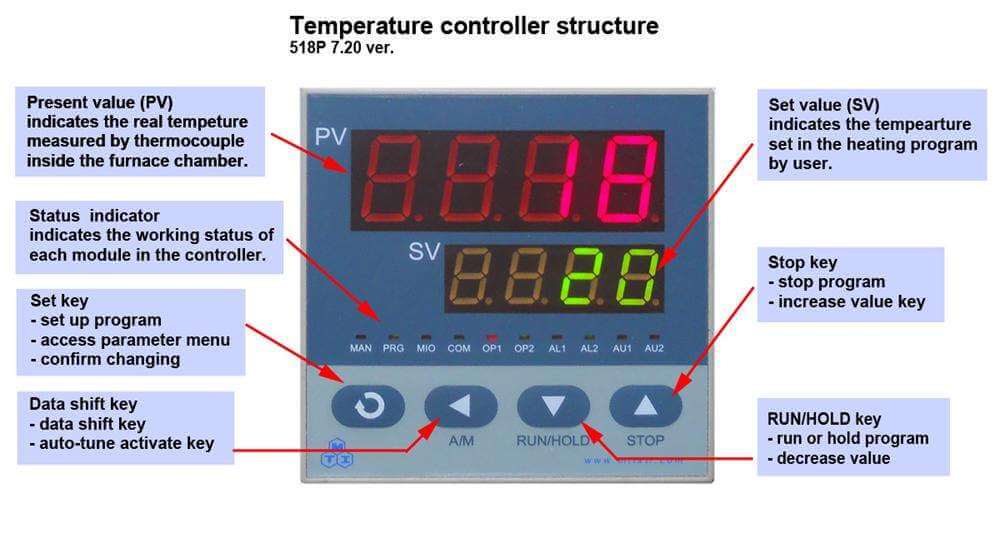

Temperature Controller

|

Two 30 segments programmable PID digital temperature controller |

Temperature Uniformity |

+/- 1°C in

heating Zone |

Tube rotating Speed |

0 - 7

RPM variable |

Furnace tilt angle |

This furnace

can not be tilted |

Max. Vacuum level |

4.5x10-2 torr (<0.1mtorr/s leaking rate if close

all the valves to airtight the tube chamber) |

Production yield |

2 kg per

batch |

Power |

8 KW Max |

Voltage |

208 - 240V

single phase (50 A Breaker required) |

Warranty |

One year

limited warranty with lifetime support |

Compliance |

CE Certified All electric

components ( >24V) are UL / MET / CSA certified The furnace

is ready to pass TUV(UL61010) or CSA certification

at extra cost. |

Product net weight |

100Kg |

Product dimension |

1300 x 600

x 1200mm |

Shipping dimension: |

49" x

40" x 70" |

Shipping weight |

500 lbs |

Warning |

1.The tube furnaces with alumina tube are designed for using under vacuum and low pressure < 0.02 MPa / 0.2 Bar/ 3 PSI 2.Never heat

the furnace while the gas release valve is closed and a positive pressure

condition exists within the furnace chamber. The pressure gauge must be used

to closely monitor the chamber condition at all times during the heating

process; please open the gas release valve immediately once the chamber

pressure has reached over 3 PSI to prevent unforeseeable damages. 3.The flow rate for gases should be limited to

< 200 SCCM ( or 200ml/min ) limit

definition for all alumina tube furnaces: * Vacuum pressures may only be

safely used up to 1500°C |

Application Notes |

1.The concept

of continuous power feeding and processing can be realized

by the use of Magnetic Fluid Sealed Swivel Coupling in line with

Volumetric Feeder and Rotary Furnace. Please view the assembling approach

diagram and video in below. 2.For CVD

coating, you may choose our multi channel Gas delivery system as

Pic below right. |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com