products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

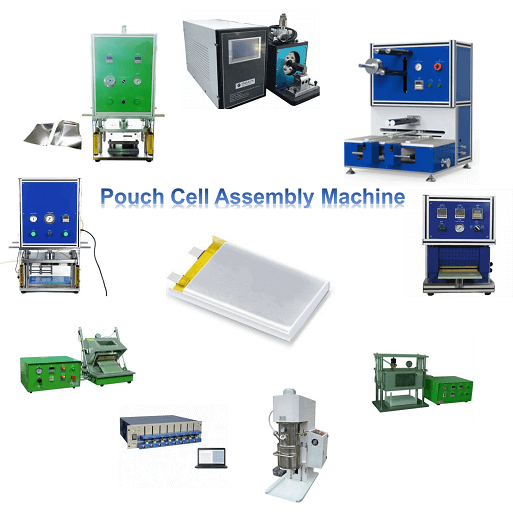

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

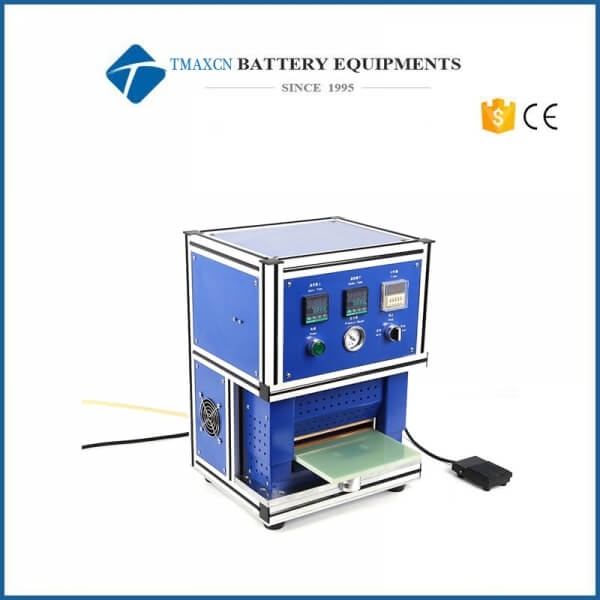

200mm-400mm Length Pouch Cell Heat Sealer For Top&Side Sealing

Model Number:

TMAX-SFZ200Compliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab Rotational Digital Touch Screen ViscometerNext:

Pouch Cell Semi Automatic Electrolyte Filling Machine with Sealing and Diffusion&Degassing Function

200mm-400mm Length Pouch Cell Heat Sealer For Top&Side Sealing

Application

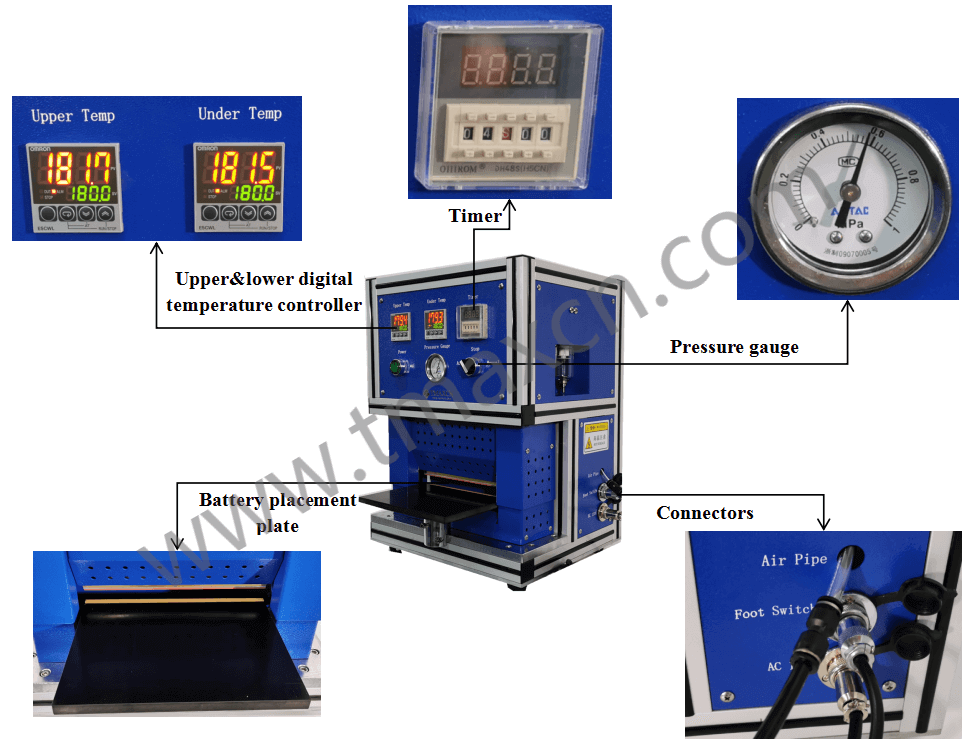

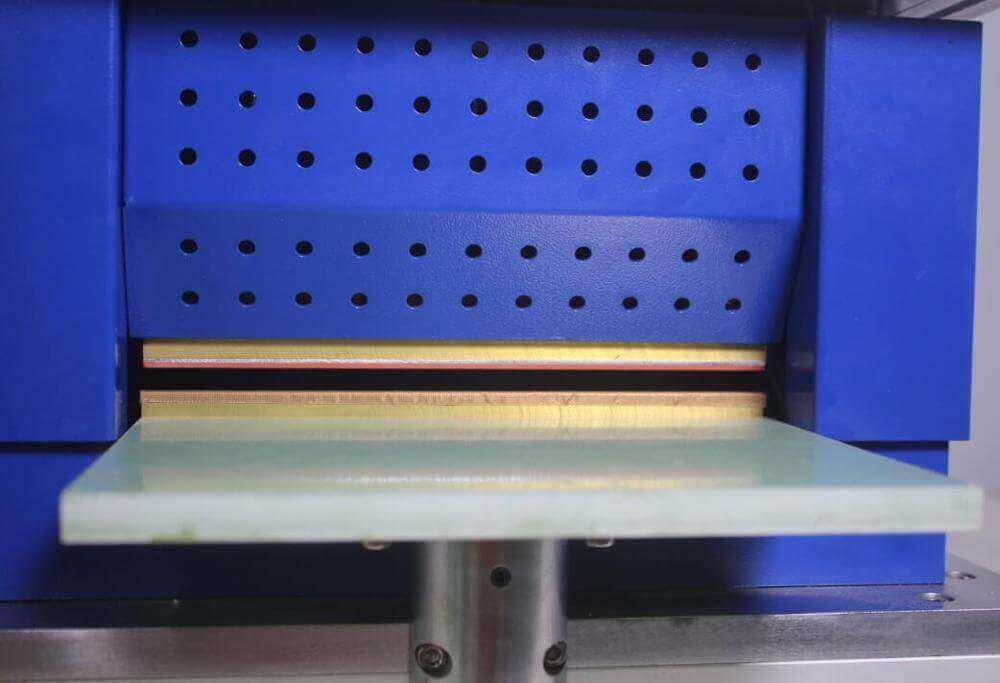

The Pouch Cell Heat Sealing Machine is designed for top-edge and side-edge sealing of pouch cell lithium-ion batteries. The machine uses a heating tube to transfer heat to the copper sealing head, which applies heat conduction to the aluminum laminated film of the battery. Under controlled pressure, the material softens and approaches a molten state, enabling secure and uniform sealing.

Key Features

· Temperature-controlled sealing heads, regulated by a thermocouple and temperature controller to maintain a stable temperature.

· Built-in pressure gauge, allowing precise control of sealing pressure.

· Firm, uniform, and smooth sealing, ensuring aesthetic and durable seals.

· Unique safety protection and anti-scalding design, ensuring safe operation.

· Energy-efficient, consuming 50% less energy compared to similar products.

· No mold change required for switching between top and side sealing.

· Compact, easy-to-operate, and reliable design, suitable for various lab and production environments.

Technical Specifications

Parameter |

Specification |

Sealing Head Length |

≤300mm |

Sealing Width |

Standard: 5mm (customizable) |

Sealing Thickness |

0.15~0.3mm |

Applicable Sealing Size |

Side Seal ≤ 300mm, Top Seal ≤ 300mm (including gas bag, customizable) |

Upper Mold Temperature |

Max. 300℃ (Recommended: 200℃) |

Lower Mold Temperature |

Max. 300℃ (Recommended: 100℃) |

Sealing Pressure |

0.5-0.7MPa (adjustable) |

Sealing Time |

Standard: 2-3s (Adjustable: 0-99s) |

Power Supply |

AC220V / 50Hz |

Power Consumption |

1000W |

Machine Dimensions |

L420xW420xH500mm |

Machine Weight |

40kg |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com