products categories

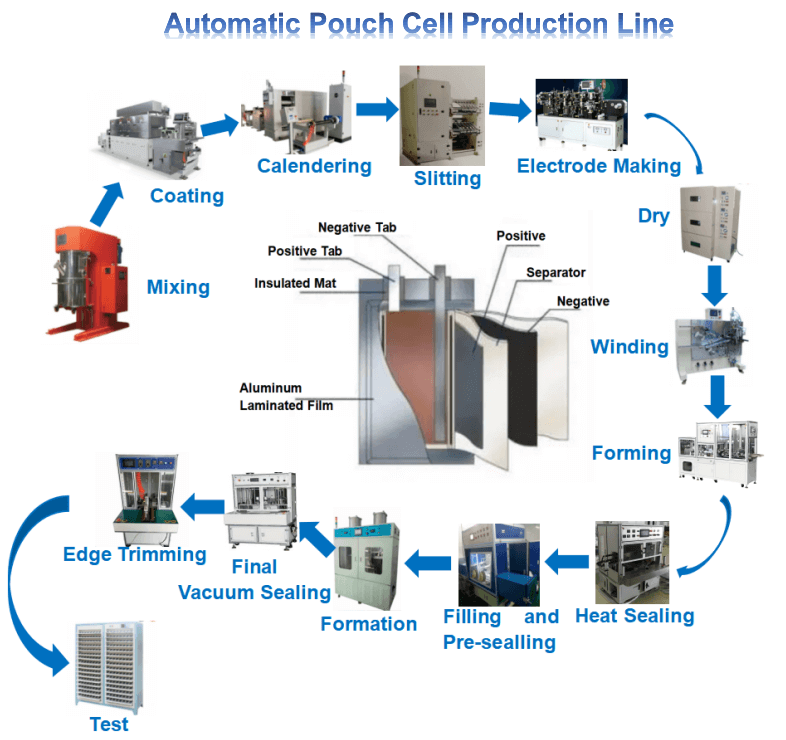

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

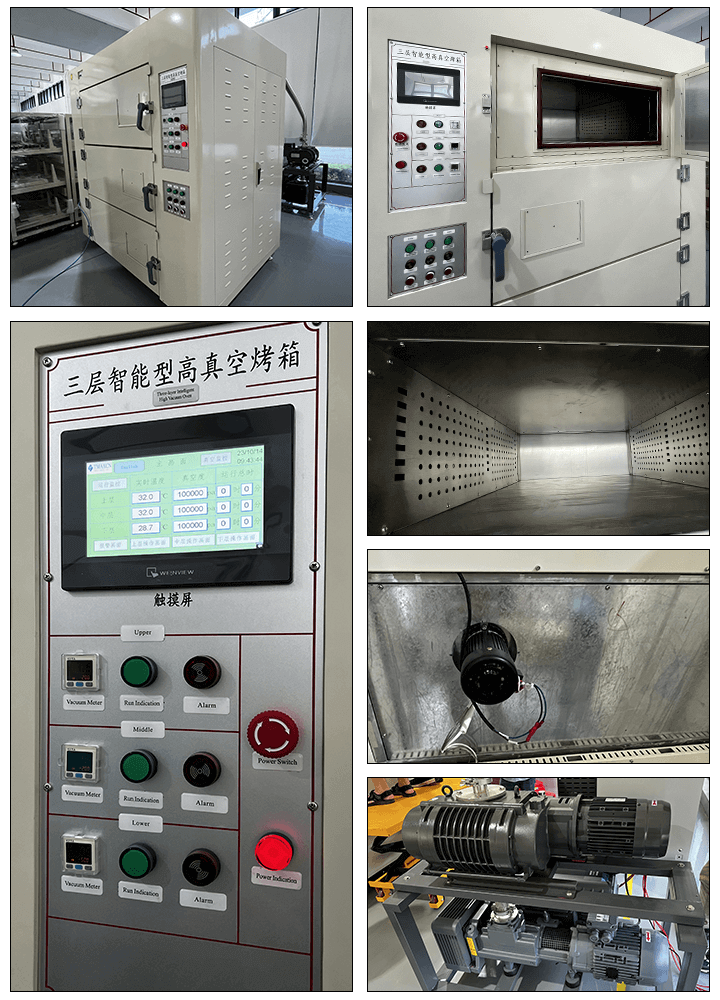

3 Layers Single Side Energy Saving Type Vacuum Drying Oven

Model Number:

TMAX-HKZN-PT03-B1Type:

Energy Saving TypeInput Power:

14KWDimension(L*W*H):

2000 H×1270 W×1150 DMax. Loading Capacity:

350 H×850 W×800 D×3 layersCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPlace of Origin:

ChinaPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

50 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

30L Planetary Dispersion Vacuum Mixer for Electrode PreparationNext:

500mmW Roll to Roll Slitting Machine for Electrode Manufacturing

3 Layers Single Side Energy Saving Type Vacuum Oven

1、 Basic structure

It consists of 5 parts:

1. Rack section;

2. Internal cavity part;

3. Vacuum pumping and nitrogen filling section;

4. Electrical control part;

5. External circulation section;

2、 Operational principle

Each machine can work continuously in a cycle; Basic process: Open the door and put the battery or electrode into the oven, then set the heating time, vacuum time, and nitrogen time. The system will automatically complete the heating and timed air exchange according to the set time parameters, completing the baking process.

3、Configuration

3.1、Inner cavity: Made of 3.0mm stainless steel, with reinforcing ribs made of iron square material

3.2、Rack: Made of 1.5mm high-quality cold-rolled sheet, consisting of two layers of insulation, with cotton made of three layered materials: aluminum silicate, aluminum foil cotton, and sound insulation cotton

3.3、Hot air system: Each layer is composed of fans, heating boxes, air ducts, air ducts, etc., which can better achieve temperature consistency

3.4、Control system: composed of PLC, touch screen, pressure sensor, high vacuum baffle valve, solid-state relay, temperature controller, electromagnetic valve group, etc

3.5、Hardware components: including doors, back covers, vacuum tubes, and other stamped parts, etc

4、Machine characteristics

4.1. Door opening method: single door opening; Elastic double-layer glass door, three-layer pressure detection, with overvoltage protection function;

4.2 Inner liner sealing ring: Silicone rubber O-ring made by pouring mold, resistant to high temperature and corrosion

4.3 Principle: Surrounding hot air external circulation. Double layer thermal insulation, with an external temperature not exceeding room temperature+20 degrees;

4.4 Heating structure: Adopting O-shaped external circulating air, with left side air outlet and right side air suction, achieving temperature consistency;

4.5. High fidelity pneumatic baffle valve, isolated three-layer independent control;

4.6. Touch screen display, automatic cycle and automatic control, completing the final step and returning to vacuum holding pressure; Digital safety temperature display;

4.7. Equipped with a multi position overtemperature protection temperature control device, it can effectively prevent temperature control safety issues such as temperature loss, and improve the accuracy of overtemperature protection;

4.8. The control screen adopts a touch screen for centralized operation, which is convenient to operate and reliable to control. The program controller adopts PLC control, which works stably and reliably;

4.9. The three-layer oven is individually controlled, and the total baking time, cycle time, vacuum pumping time, and drying time can be set separately. After setting the parameters, the automatic button can be pressed to enter the automatic baking program. When the time reaches the baking time, it will automatically shut down. If the temperature exceeds the safe temperature value, an alarm will be triggered and the red indicator light will light up, and heating will automatically stop. The alarm information will be displayed on the display screen;

4.10. Fill the box with dry air to any set value between -0.1Mpa and -0.02Mpa, and the inflation can be automatically stopped;

4.11. During normal operation, the fault prompt alarm and the cause of the fault can be described on the screen;

4.12. Vacuum tubes have anti-corrosion properties;

4.13. Program interlocking to prevent inter layer gas leakage.

5、Technical parameters:

SN |

Item |

Parameter |

1 |

Heating principle |

External circulation hot air heating |

2 |

Power |

380V 50HZ 14KW |

3 |

Gas source |

Dry air: 0.1-0.2Mpa/vacuum:-0.098- -0.1Mpa/compressed air: 0.4-0.5Mpa |

4 |

Temperature |

Room temperature to 120℃ |

5 |

Vacuum degree |

When drawn between -0.1-0.098Mpa, the digital display maintains a pressure of ≥ 95% at room temperature and normal pressure for 24 hours |

6 |

Display error |

Set value and stable displayed value≤±1℃ |

7 |

Thermal insulation performance |

The outer wall temperature shall not exceed 45 degrees (excluding glass doors) |

8 |

Temperature uniformity |

50MM away from the wall at each point inside the cavity: ≤ ± 3.5 ℃ under normal pressure |

9 |

String temperature property |

≤20℃(Within 100 degrees of temperature rise in adjacent layers, only within 20 degrees higher than room temperature) |

10 |

Response speed |

Within 30 minutes from room temperature to 85 degrees Celsius, the surface display reaches the set value, and the unloaded core temperature stabilizes for 90-120 minutes |

11 |

Vacuum pumping and nitrogen filling positions and interface specifications |

The interface is located at the rear of the device; The vacuum connection is DN20, and the dry gas connection is a ¢ 12mm gas pipe connection |

12 |

Inner liner size (201 material) |

350 H×850 W×800 D×3 |

13 |

Outer size |

2000 H×1270 W×1150 D |

14 |

Appearance color (baked paint treatment) |

Grey white orange (customer can provide color palette) |

6、Electrical configuration:

SN |

Item |

Specification |

1 |

PLC |

Huichuan |

2 |

Touch screen |

7-inch Huichuan color screen |

3 |

Temperature controller |

Digital intelligent temperature controller/microcomputer PID automatic calculation |

4 |

Temperature mode |

PID+SSR(thyristor), Shanghai Yatai |

5 |

Over temperature protection |

Shanghai Yatai Temperature Controller |

6 |

Temperature sensor |

Hualing K-type thermocouple |

7 |

Vacuum gauge |

Digital vacuum gauge/-101.0-101.0 kPa positive and negative pressure universal type, Taiwan Jingdeng |

8 |

Vacuum valve/nitrogen valve |

Vacuum baffle valve |

9 |

Alarm |

Yijia |

10 |

Heating tube |

Customized |

11 |

Control mode |

Each chamber works independently, and the heating, vacuuming, and nitrogen filling modes are PLC automatic circulation. The operation of each working section is set through the touch screen |

7、Installation conditions

7.1 The distance between the front of the oven and the wall shall not be less than 1500mm, and the distance between the left and right rear sides shall not be less than 500mm. Users must provide independent power distribution switches and be responsible for connecting external power sources to the equipment.

7.2 Installation area conditions (provided by the buyer):

7.2.1 Power supply: three-phase four wire AC 380 ± 38V, frequency: 50 ± 1Hz;

7.2.2 Vacuum source: pressure -0.1MPA, vacuum pipe DN20 tower joint

7.2.3 Nitrogen source: pressure 0.1~0.2MPA, nitrogen pipeline ¢ 12 gas pipe

7.3 Compressed air: 0.4~0.6MPA, ¢ 8 air pipe

7.4 Energy consumption

7.4.1 Maximum hours ≤ 12kw/hour 7.5, environmental requirements

7.5.1 Temperature -5~35 ℃, humidity ≤ 40%

7.5.2 No flammable or explosive gases, liquids, or solids in the surrounding area

7.5.3 Avoid baking flammable materials, gases, and explosives inside the box.

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588