products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

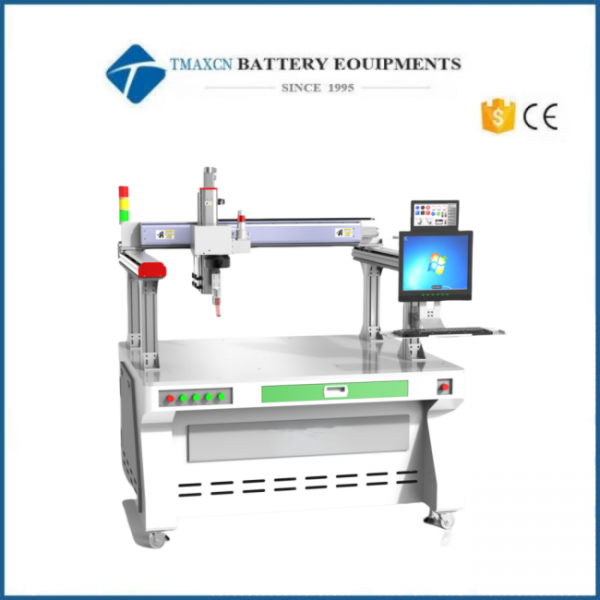

3000W Gantry Galvanometer Laser Welding Machine

Model Number:

TMAX-YLD—LBM3000Type:

AutomaticInput Power:

13KWDimension(L*W*H):

1600*1400*3000mmCompliance:

CE CertifiedWarranty:

1 yearPlace of Origin:

ChinaMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

45 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

6000W Cross Line Continuous Laser Welding MachineNext:

3000W Fiber Laser Galvanometer Welding Machine for Prismatic Cell Welding

3000W Gantry Galvanometer Laser Welding Machine

Ⅰ.Function Overview :

The TMAX-YLD-LBM3000 continuous fiber laser welding machine is suitable for welding metal materials such as copper and aluminum. This machine adopts a high-strength gantry bed structure design, and its stable body ensures stability during the welding process; Using advanced continuous laser as the light source, it has higher photoelectric conversion efficiency, lower power consumption, and higher beam quality; Fiber laser has the advantages of compact structure, small volume, and ready to use performance; Due to its flexible laser output mode, it can be easily integrated with system equipment; The high-precision and high-strength screw linear module serves as the operating transmission mechanism, and the highly responsive servo motor power output ensures high speed and accuracy of operation. It is a key equipment in the field of new energy lithium battery PACK modules.

The laser beam quality of this line equipment is excellent, the welding speed is fast, and the welding pool is beautiful and firm, providing an efficient, stable, and perfect welding solution for the lithium battery welding process.

Ⅱ.Equipment parameter index characteristics :

1)--Weldable material thickness:0.5mm-2.0mm;

2)--Effective travel range: (X-axis:870mm)×(Y-axis:600mm)×(Object workpiece height:400mm);

3)--Welding speed:10mm/s(Adjustable)

4)-- Laser type: continuous

5)--Laser power :3KW(Adjustable)

6)-- Laser working medium: fiber optic

7)--Laser service life: ≥ 5 years

8)--Welding material: aluminum bar, copper sheet, nickel strip

9)--Welding can be done in two modes: continuous welding and pulse spot welding

10)--Weld penetration depth: The contact surface penetration depth is adjustable from 0.5-1mm

11)--Welding strength: The tensile strength of the solder joint is greater than the material's failure strength.

Ⅲ.Equipment advantages and characteristics :

1)--Maintenance-free operation;

2)--Support adjustable welding parameters such as motion speed;

3)--Support real-time fault alarm prompts;

4)--Support manual and automatic operation modes, support linear and circular interpolation;

5)--Can perform graphic welding processing on laser points, straight lines, circles, squares, and other planes composed of any shape;

6)--The welding field mirror adopts imported lenses, which can withstand high temperatures of laser power;

7)--The operating system is concise, easy to understand and learn, and the training is simple and easy to get started with;

8)--When welding, use the function of blowing air with an air knife to prevent smoke and welding slag from affecting the welding effect;

9)--The welded joint adopts water cooling circulation for local cooling to ensure the stability and consistency of welding quality;

10)--During welding, pneumatic pressure heads are used to press the connecting pieces and poles tightly to prevent poor adhesion and virtual welding phenomenon;

11)--Specialized welding software, welding process expert, data saving and calling function;

12)--High precision screw drive, high response, high speed, high-precision brand servo motor

Ⅳ.Environment condition:

1)--Ambient temperature:5ºC-35 ºC

2)--Humidity:20%-90%

3)--Air Pressure :0.5~0.6 Mpa

4)--Supply voltage:380V-50Hz/60Hz

5)--Total power:≤13KW

6)--Area to weight ratio:≤500kg/M²

7)--Grounding type: direct grounding type

8)--Installation environment: flat, without vibration and impact

Ⅴ.Machine external dimensions and specifications:(L)1400mm×(W)1200mm×(H)3000mm

Ⅵ.The main components and configurations of the machine equipment are:

Configuration Name |

Item |

Specification |

Brand |

Main machine |

Cabinet body |

TMAX-YLD-3000 |

TMAX |

|

Linear module X-axis |

Effective travel greater than 850mm |

TMAX |

|

Linear module Y-axis |

Effective travel greater than 600mm |

TMAX |

|

Linear module Z-axis |

Effective travel greater than 400mm |

TMAX |

|

Host countertop |

15mm steel plate |

TMAX |

|

Air blowing cooling device for wind blade pressure head |

/ |

TMAX |

Laser |

Fiber laser |

C3000W |

Raycus |

Galvanometer |

Laser galvanometer |

YL3000 |

Light of wisdom |

Cooling system |

Laser independent chiller |

/ |

DOLUYO |

Drive system |

XY axis servo motor |

400W,without brakes |

XINJIE |

|

Z-axis servo motor |

400W,wit brakes |

XINJIE |

Control system |

Laser card |

Multifunctional welding control software |

TMAX |

Display system |

Liquid crystal display |

15inch |

Lenovo |

Ⅶ.Laser parameters:

Average laser power(W) |

3000W |

Laser wavelength(nm) |

1070 |

Operation module |

Continuous/Modulation |

Maximum modulation frequency(KHz) |

Continuous |

Laser mode |

Yv04 |

Beam quality(M2) |

<0.373 |

Output connector |

QBH |

Power adjustable range(%) |

(10-100)% |

Fiber length(m) |

10M |

Input power supply |

380V |

Cooling method |

Water-cooling |

Control model |

RS232 |

Working temperature ℃ |

10℃-30℃ |

Focal length F(mm) |

200 |

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588