products categories

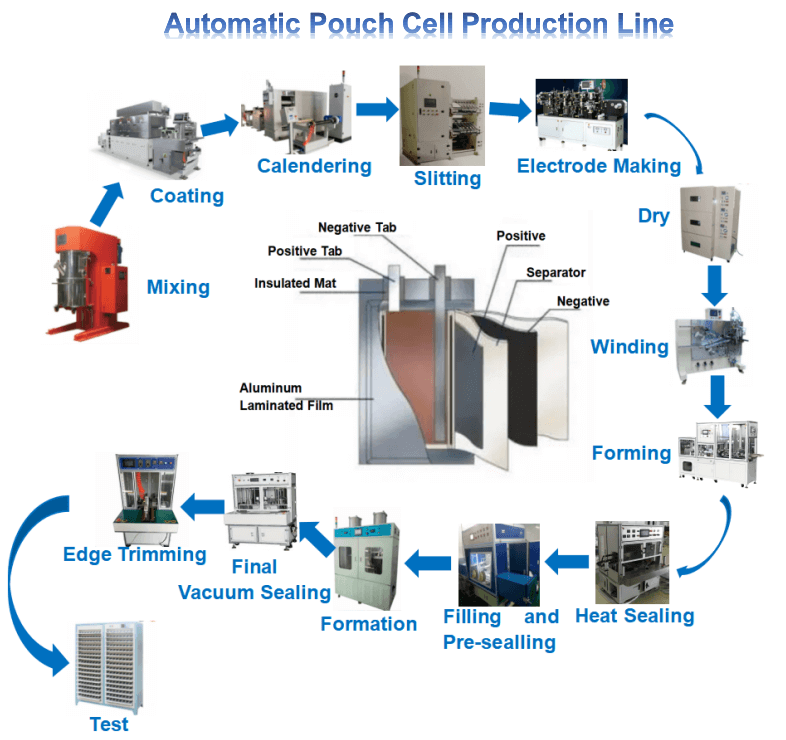

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

30L Battery Slurry Planetary Vacuum Mixer

Model Number:

TMAX-DMS30LCompliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Double Servo High Speed Die Cutting MachineNext:

Battery Electrode Extrusion Slot Die Coating Machine

30L Battery Slurry Planetary Vacuum Mixer

Specifications

Mixer specifications

1-1 Product name and specification |

A. Planetary dispersion vacuum mixer; B. Model:TMAX-DMS30L(4kw/2P-3kw/4P) |

1-2 Basic structure |

A. Hydraulic lifting vessel type; B. 6-axis revolution direct material temperature measurement mode (the only way to accurately control the temperature); C. Double dispersion axis + double mixing axis + single scraping wall + single temperature measurement - (6 axis) |

1-3 Mixing vessel |

A. Dimensions:Dia. 340mm×330mm; B. Design volume: 30L; C. Effective volume: 25L. |

A. Liner material: SUS304; B. After turning the inner liner wall, the mirror surface is polished to ensure good roundness; C. The upper flange plane of the mixing barrel and the upper barrel body are sealed by a sealing ring; D. There is one G1 "(DN25) discharge valve at the bottom of the barrel. E. The jacket with reinforced guide plate (G1 / 2 "inlet / outlet interface) can cool or heat the processed material with cold water (oil) or hot water (steam or hot oil). |

|

1-4 Upper vessel (kettle cover) |

A. Material: SUS304; B. One Φ 70 powder hopper, which can be switched on and off quickly; one spotlight; with two small windows (one spotlight port and one observation hole), one vacuum pressure gauge, and other necessary connecting pipes (vacuum / vent / standby). |

1-5 Mixing principle |

Single agitated pulp and a plurality of serrated dispersing discs installed on the high-speed dispersing shaft are used for both rotation and revolution; at the same time, combined with the low clearance design of the agitating pulp, there is no dead angle, and the strong kneading interference motion and up-down / left-right circulation motion of the low-speed agitating paddle, as well as the high-speed shearing and scattering function of the dispersing disc, to ensure that the materials are fully dispersed, mixed and not deposited. |

1-6-1 Revolution/mixing motor, frequency converter and reducer |

A. Quantity: one; B. Motor power: 3kw / 4P; C. With 3KW frequency converter matched with motor; D. Equipped with cycloid pinwheel reducer BL2, the reduction ratio is about I = 29, and the service factor FA = 1.0. |

1-6-2 Planetary revolution speed |

Speed:0~50 rpm,adjustable |

1-6-3 Wall scraper |

Quantity: 1 group; Scraping material: SUS304 and Teflon; Same as the revolution speed. |

1-7-1 Mixing blade / mixing speed |

Speed:0~70rpm, adjustable |

1-7-2 Mixing blade |

A. Material: SUS304; B. Quantity: 2 (groups); |

1-7-3 Selection of mixing blade |

A. Standard: "spiral twist"; |

1-8-1 Distributed motor and frequency converter |

A. Quantity: one; B. Motor power: 4kw / 2p; C. With 4kw frequency converter matching with motor. |

1-8-2 Dispersion speed(rotation) |

A. Speed: 0 ~ 3800 rpm, adjustable; B. Linear speed: 0 ~ 12m / S; |

1-8-3 Dispersion axis and disc |

A. Material: SUS304; B. Diameter of dispersion disk: Φ 80mm; C. One, a dispersing disk is installed on the dispersing shaft to ensure better dispersion / mixing. |

1-9 Lifting (mixing barrel) |

A. Hydraulic lifting B. Lifting height: ≤ 380. |

1-10 Vacuum system |

A. The mixing and dispersion process can be carried out under vacuum condition; vacuum degree: ≤ - 0.1MPa |

C. Vacuum pump 2X-4, 0.55kw/4P motor (prepared by customer) |

|

C. With vacuum surge tank and switch. |

|

D. Dynamic seal: mechanical seal; static seal: O-ring seal. |

|

E. Keep the pressure for 24 hours, and do not leak oil into the mixing tank or under the condition of keeping the pressure. (this machine can keep the air tight, if there is such a requirement, special instructions can be provided). |

|

1-11 Positioning system |

A. With positioning adjustment device and locking device, it can accurately position the mixing barrel and upper can body, and prevent rotation. B. The positioning stop of the lower flange of the upper can body is precisely matched with the mixing barrel to ensure that the position of the mixing barrel is reasonable and the positioning is accurate. |

1-12 Distribution cabinet |

The function display and operation of vacuum device, frequency conversion speed regulation, temperature display (control), spotlight, lifting, operation emergency stop, etc. in the operation of the equipment are carried out on the power distribution cabinet. Note: mixing and dispersion has timing function. |

1-13 Safe operation |

A. Depending on the frequency converter and limit travel switch, through the specially designed control route, the can body can automatically stop when it reaches the specified position. |

B. In the process of can body rising, the mixing / dispersing part of the equipment cannot be started; similarly, when the machine is running the mixture, the can body cannot be lowered and the mixing bucket cannot be opened. |

|

C. The special design of vacuum buffer tank can effectively prevent the return of vacuum pump oil to the mixing drum. |

|

D. A door bolt type buckle is arranged on the kettle cover and the mixing barrel to prevent the mixing barrel from falling automatically. |

|

1-14 Temperature measurement method |

Measure the material temperature: 0-300 ℃, the temperature probe moves with revolution, and directly contacts the material |

1-15 Worktable |

Stainless steel laboratory working platform |

1-16 Total host power |

4.4KW |

1-17 Working voltage / frequency |

380V/50Hz/3Phase; Control voltage: 220V. |

2. Slurry discharge machine( positive pressure extrusion) - YLJ-30L(1.5kw/4P)

1. Structural form |

The frame is single cantilever type. |

||

2. Lifting mode |

The frame is fixed on the workbench. |

||

3. Pressing method |

Use the hydraulic cylinder to drive the press plate to press the material. |

||

4.Drive part of pressing plate |

Double acting oil cylinder: Φ63/D32×S250FA; Quantity: one (set). |

||

5. Press plate |

The nominal size is Φ 240, matching with the mixing drum; the plate is equipped with an exhaust port. |

||

6. Locking mode of mixing drum |

Mechanical locking. |

||

7. Discharge method |

Discharge. |

||

9. Basic technical indicators |

9-1. Motor power of oil station |

9-2 Pressure per unit area of pressing plate |

9-3. Oil pump flow and maximum output pressure |

≤2.2KW/4P |

9kg/cm2 |

Plunger: 1.6L/min—21MPa/max. |

|

9-4. Maximum press pressure |

9-5 Rated system pressure |

9-6 Oil cooling area |

|

3.3 tons |

12MPa |

Air natural cooling |

|

10-1 Consumable parts |

A. "O" seal ring: Φ340×Φ10; B. Material: fluororubber; C. Quantity: 1 spare. |

||

10-2 use of wearing parts |

Sealing groove at pressing plate. |

||

11. Transfer mode of mixing drum |

Standard selection: guide rail type transfer mixing drum is transferred between the main machine and the press. |

||

12. Notes |

Share the power distribution cabinet and oil station with the main engine. |

||

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com