products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +8618659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

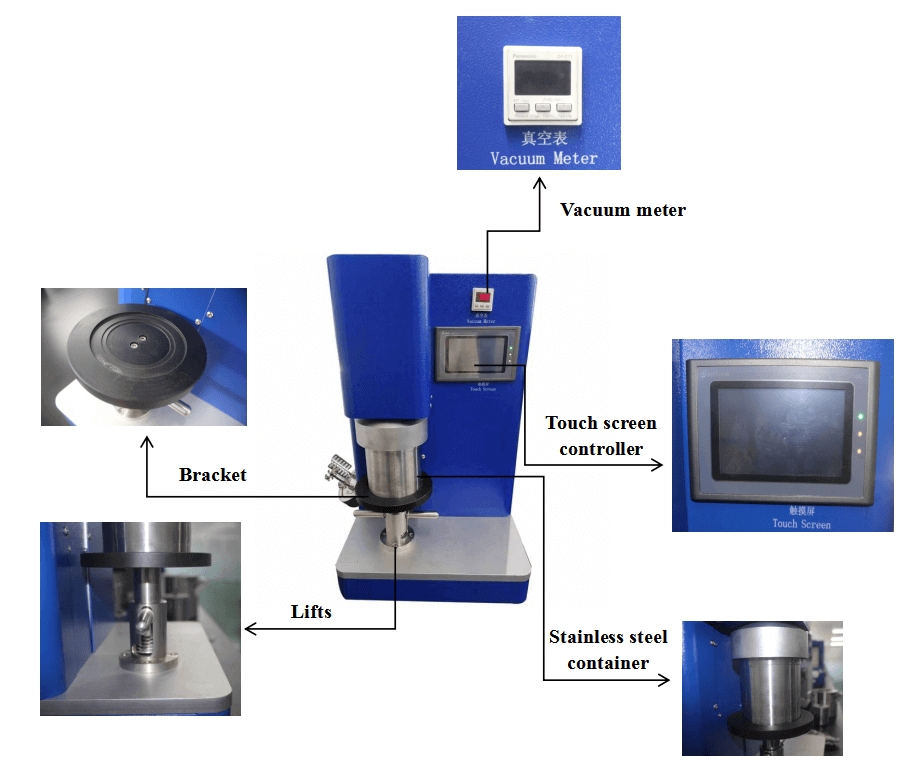

500ml Compact Dual-Shaft Planetary Vacuum Mixer Machine

Model Number:

TMAX-XJBInput Power:

200WDimension(L*W*H):

330 mmx320 mmx570 mmNet Weight:

40 kg (88 lbs)Compliance:

CE CertifiedWarranty:

1 yearPlace of Origin:

Fujian, China (Mainland)MOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +8618659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

500ml Compact Dual-Shaft Planetary Vacuum Mixer Machine

Product Description

This vacuum mixer is a high-efficiency device that integrates vacuum mixing and dispersion, making it ideal for mixing cathode and anode slurry in battery research, as well as for blending powder materials and various ceramics. The mixing process is carried out in a vacuum environment, effectively eliminating air bubbles, thereby improving material filling and enhancing the density and compactness of the formed structure.

Features & Functions

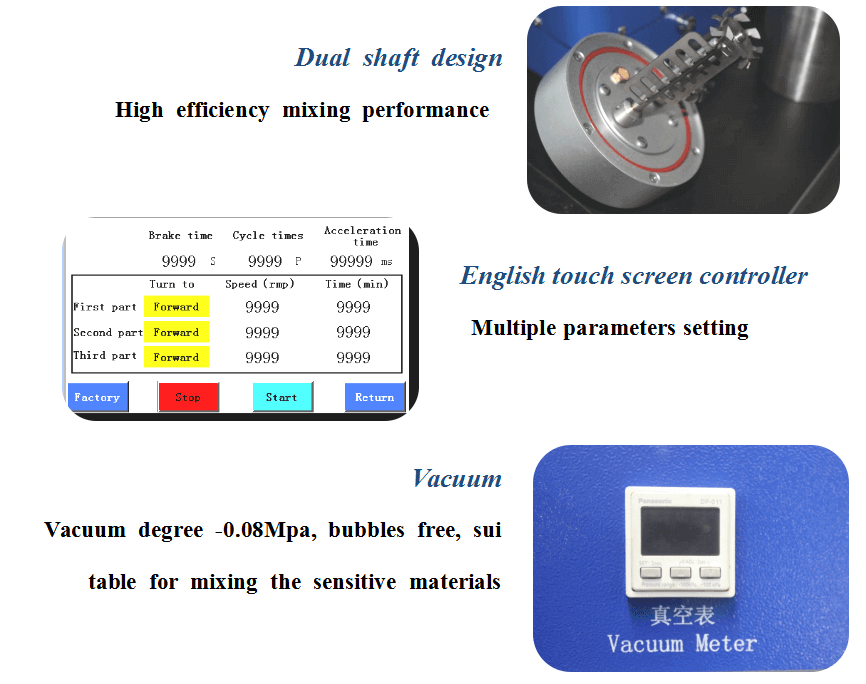

· Designed with forward and reverse mixing functionality, ensuring high-speed mixing of high-viscosity slurries with excellent uniformity.

· Operates in a vacuum environment, effectively removing air bubbles generated during mixing; equipped with a built-in vacuum system.

· Supports multi-stage speed control, allowing users to set different mixing speeds and times for each stage.

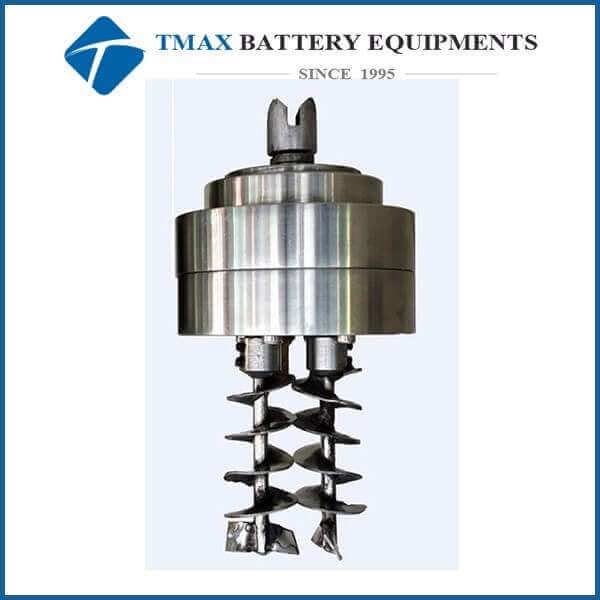

· Standardized with a dual-axis planetary mixing structure and screw-type mixing paddles. Different stirring shaft configurations and combinations are available based on the mixing tank size.

· Equipped with a support frame design for easy operation and safety assurance during the vacuum mixing process.

· The machine has a compact and modern design with a simple yet elegant appearance.

· Small footprint, saving space.

Technical Parameters

Parameter |

Specification |

Mixing Speed |

Max 600 RPM |

Multi-stage Function |

Three-stage speed setting |

Mixing Tank Capacity |

500ml stainless steel vacuum mixing tank (other specifications available) |

Mixing Time |

Adjustable from 0 to 600 minutes |

Power Supply |

AC220V(customizable) |

Rated Power |

200W |

Machine Dimensions |

330mm × 320mm × 570mm (L × W × H) |

Machine Weight |

Approx. 35kg |

Standard Configuration |

Dual-axis screw-type mixing paddles (customized based on tank design); built-in vacuum pump with vacuum level of -0.08MPa |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com