products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

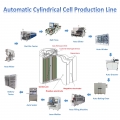

Automatic 18560 21700 32650 26650 etc Cylindrical Cell Production Line/Lithium Cylindrical Battery Production Plant

Model Number:

TMAX-Auto-CY-01Type:

AutomaticCompliance:

CE CertifiedWarranty:

One year limited with lifetime supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

300L Planetary Vacuum Mixer for Battery Production LineNext:

18650 26650 21700 32650 Cylindrical Cell Laboratory Fabrication Plant

Automatic 18560 21700 32650 26650 etc Cylindrical Cell Production Line/Lithium Cylindrical Battery Production Plant

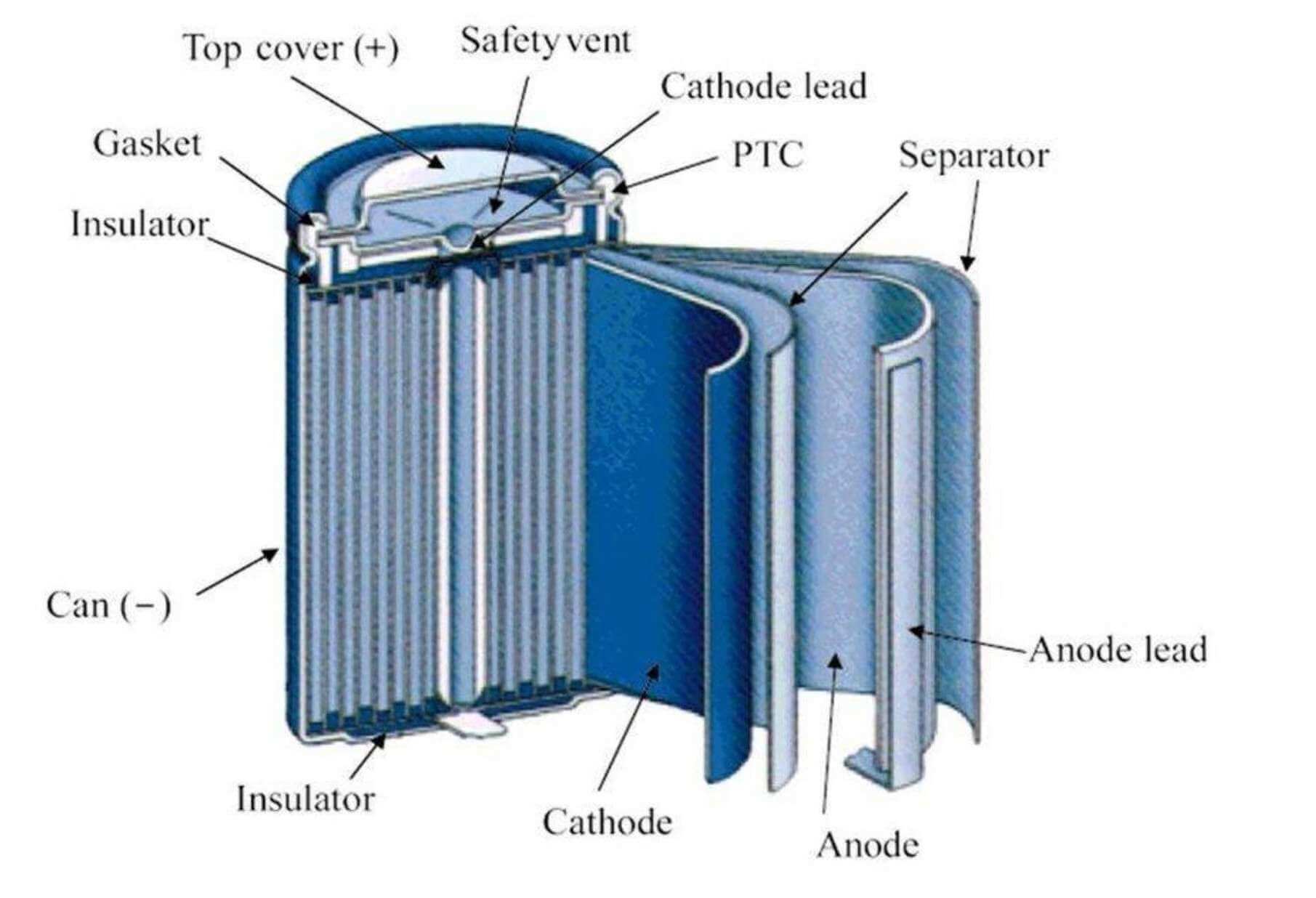

Ⅰ、Cylindrical cell components:

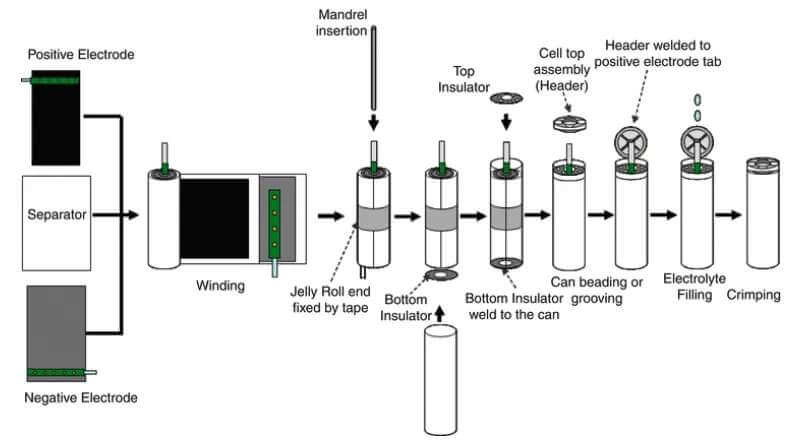

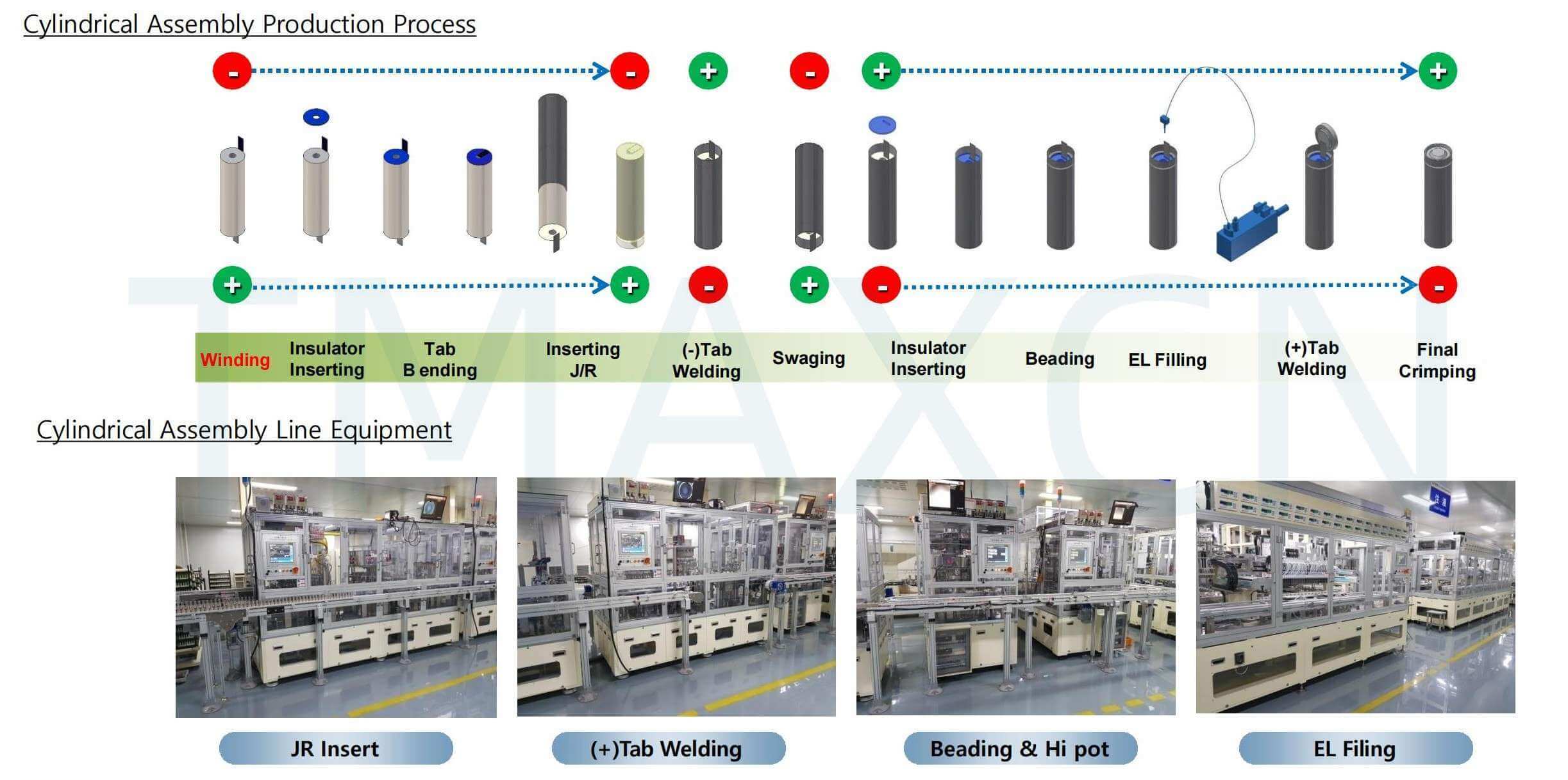

Ⅱ、Flow chart for how cylindrical cells are assembled:

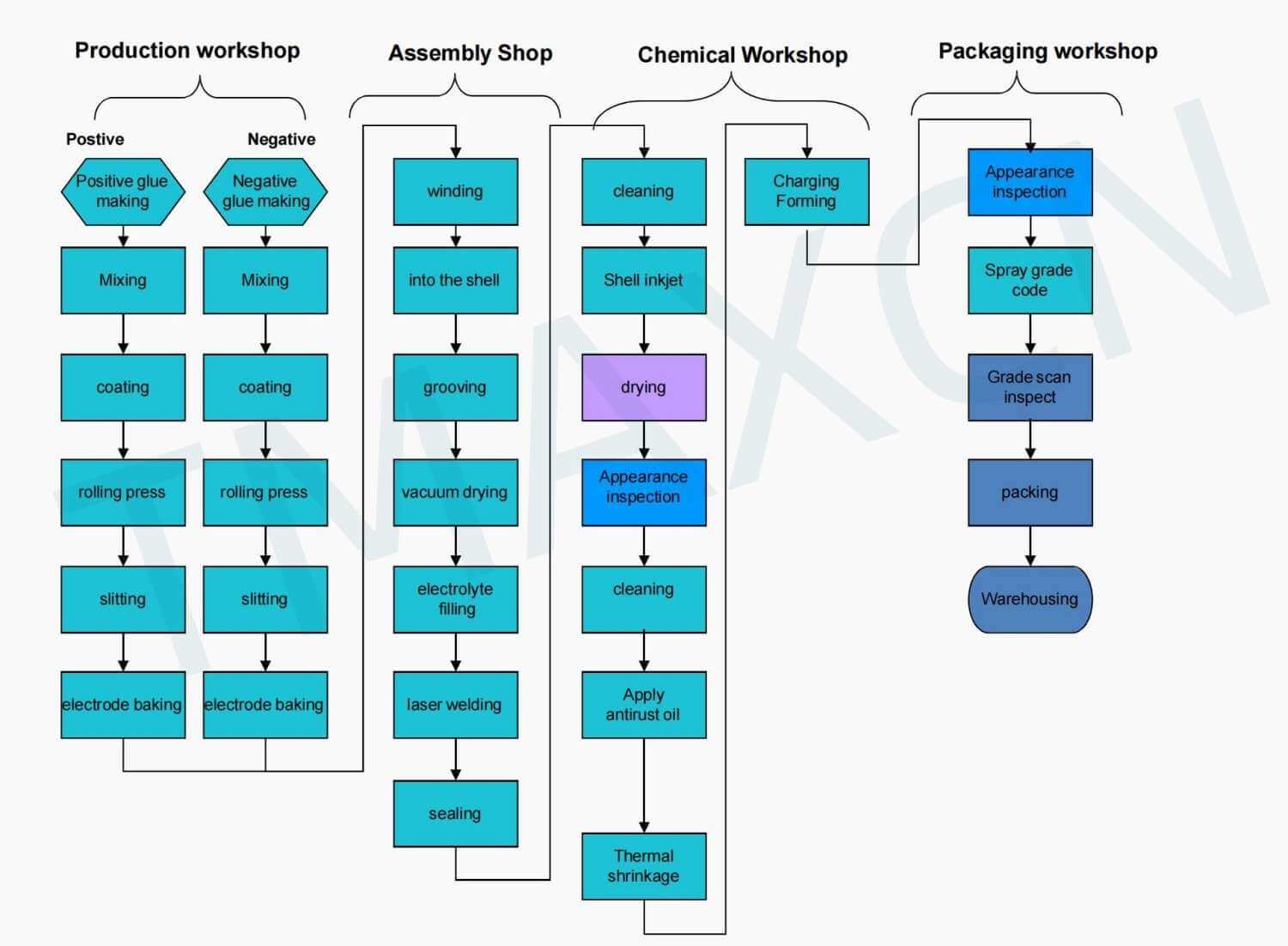

Ⅲ、Cylindrical Battery Process Chart:

Ⅳ、Cylindrical Cell Drawing Information required for designing the battery formula.

4.1 General information on target cell technology:

Dimension |

Unit |

Cell Design |

Chemistry |

|

|

Capacity |

Ah |

|

Nominal Voltage |

V |

|

Cell format |

|

|

Cell weight |

g |

|

Target capacity per year(net) |

Gwh |

|

Target OEE |

% |

|

Shift per day |

# |

|

Hours per shift |

h |

|

Working days per year |

d |

4.2 Further information on cell technologies:

Housing

Jelly Roll

Electrode Spec

Electrolyte

Anode Slurry

Cathode Slurry

Formation & aging protocol

EOL

Final grading

4.3 Cell drawings

Ⅴ、Machinery List:

S NO. |

Workshop |

Equipment Name |

1 |

Cathode |

Oven |

2 |

Planetary Vacuum Mixer |

|

3 |

Turnover Barrel with lifting system |

|

4 |

Viscometer |

|

5 |

Coating Machine |

|

6 |

Thickness Gauge |

|

7 |

Continue Pressing Machine |

|

8 |

Auto Slitting Machine |

|

9 |

Baking Oven |

|

10 |

Anode |

Deionized water machine |

11 |

Planetary Vacuum Mixer |

|

12 |

Turnover Barrel with lifting system |

|

13 |

Viscometer |

|

14 |

Coating Machine |

|

15 |

Thickness Gauge |

|

16 |

Continue Pressing Machine |

|

17 |

Auto Slitting Machine |

|

18 |

Baking Oven |

|

19 |

Assemble |

Auto Winding Machine |

20 |

Short Testing Machine |

|

21 |

Bottom Shell Welding Machine |

|

22 |

Auto Grooving Machine |

|

23 |

Baking Oven |

|

24 |

Filling and |

Glove Box |

25 |

Laser Welder |

|

26 |

Linear Sealing Machine |

|

27 |

Battery Cleaning Machine |

|

28 |

PVC Shrinkage Machine |

|

29 |

Cartoning machine |

|

30 |

Grading |

Formation Machine |

31 |

Computer |

|

32 |

High temperature storage |

|

33 |

Normal temperature storage |

|

34 |

Cell Inkjet Printer |

|

35 |

OCV1 |

|

36 |

OCV2 |

|

37 |

OCV3(Sorting machine) |

|

38 |

Grading Machine |

|

39 |

Sorting machine |

|

40 |

Other |

NMP recovery system |

41 |

Plant dehumidification system |

|

42 |

Purified water |

|

43 |

Other Necessary |

Vacuum Pump + Compressed Air |

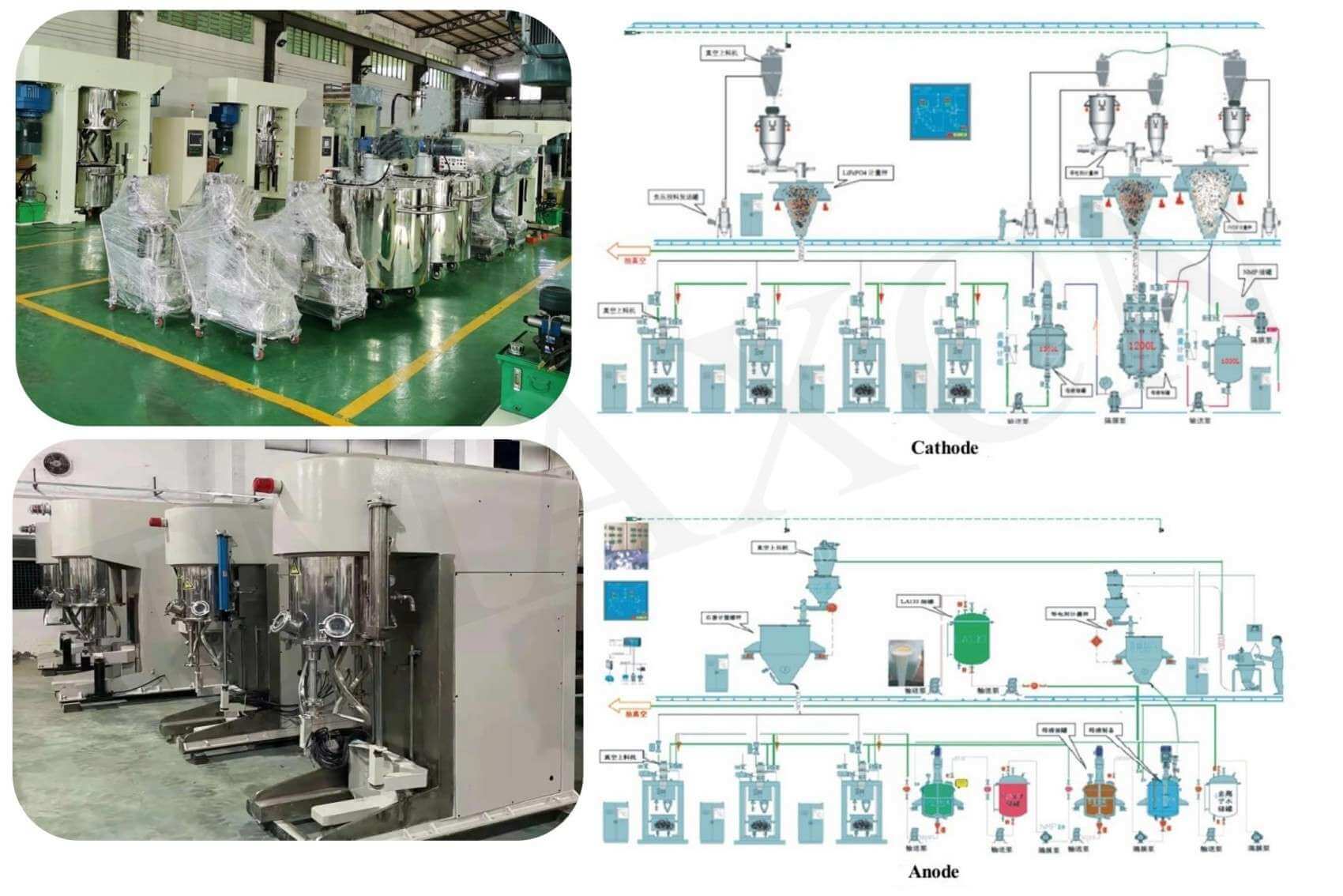

Ⅶ、Battery Prodcution Workshop Reference:

Ⅷ、Battery Production Line Factory Design Reference:

Ⅷ、Procurement process

TMAX follows a comprehensive procurement process to ensure a seamless experience for our customers.

1) Initial Consultation: We have an in-depth discussion with the customer to understand their battery production requirements, machine specifications, and budget constraints.

2) Proposal Preparation: Based on the consultation, we create a detailed proposal that outlines our recommended battery-making machines, pricing, delivery timelines, and additional services or support.

3) Proposal Presentation: We present the proposal, highlighting the features and benefits of our machines, addressing customer questions, and explaining how our solution meets their needs.

4) Negotiation and Agreement: We engage in negotiations to address concerns and modify the proposal if needed, aiming to reach a mutual agreement on pricing, terms, and conditions.

5) Purchase Order: The customer issues a purchase order (PO) that formalizes the agreement, specifying quantities, prices, delivery dates, and contractual obligations.

6) Order Fulfillment: We manufacture or source the battery-making machines according to agreed specifications, conducting quality control checks to ensure high performance and reliability.

7) Shipment and Delivery: We handle packaging, transportation, and customs clearance, providing tracking information and updates on the shipment's status.

8) Installation and Training: Our technicians offer installation services and comprehensive training on machine operation, maintenance, and troubleshooting.

9) Post-Sales Support: We provide ongoing customer support, including assistance with spare parts, maintenance, upgrades, and expansions, to ensure customer satisfaction.

By following this streamlined procurement process, we deliver high-quality battery-making machines tailored to our customers' requirements while providing excellent support throughout their lifecycle.

Ⅸ、 Manufacturing Cycle and Planning

No. |

Project |

1st month |

2nd month |

3rd month |

4th month |

5th month |

6th month |

||||||

1 |

◎ Confirmation of idea/plan/specification |

|

|

|

|

|

|

|

|

|

|

|

|

2 |

◎ Customized design for key parts |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

◎ Mechanical part design |

|

|

|

|

|

|

|

|

|

|

|

|

4 |

◎ Control part design |

|

|

|

|

|

|

|

|

|

|

|

|

5 |

◎ Procurement of processed parts/outsourced parts |

|

|

|

|

|

|

|

|

|

|

|

|

6 |

◎ Mechanical assembly |

|

|

|

|

|

|

|

|

|

|

|

|

7 |

◎ Electrical debugging |

|

|

|

|

|

|

|

|

|

|

|

|

8 |

◎ Single test |

|

|

|

|

|

|

|

|

|

|

|

|

9 |

◎ Linkage trial operation and on-site customer placement |

|

|

|

|

|

|

|

|

|

|

|

|

10 |

◎ Trial run/final acceptance |

|

|

|

|

|

|

|

|

|

|

|

|

Our Certifications

Cooperative Brand

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com