products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Automatic Assembly Line of Electric Vehicle /Battery Energy Storage Battery/ Power Battery Pack

Model Number:

TMAX-Auto-pack-01Type:

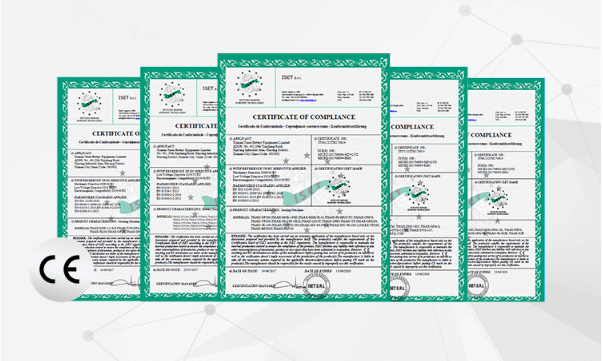

AutomaticCompliance:

CE CertifiedWarranty:

2 Year limited warranty with lifetime supportPlace of Origin:

ChinaShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

70V 10A Charging 20A Lithium Battery Pack Charging and Discharging MachineNext:

Li Battery Assembly Automation Line for Electric Tools /Solar Products / EV /Energy Storage Batteries

Automatic Assembly Line of Electric Vehicle /Battery Energy Storage Battery/ Power Battery Pack

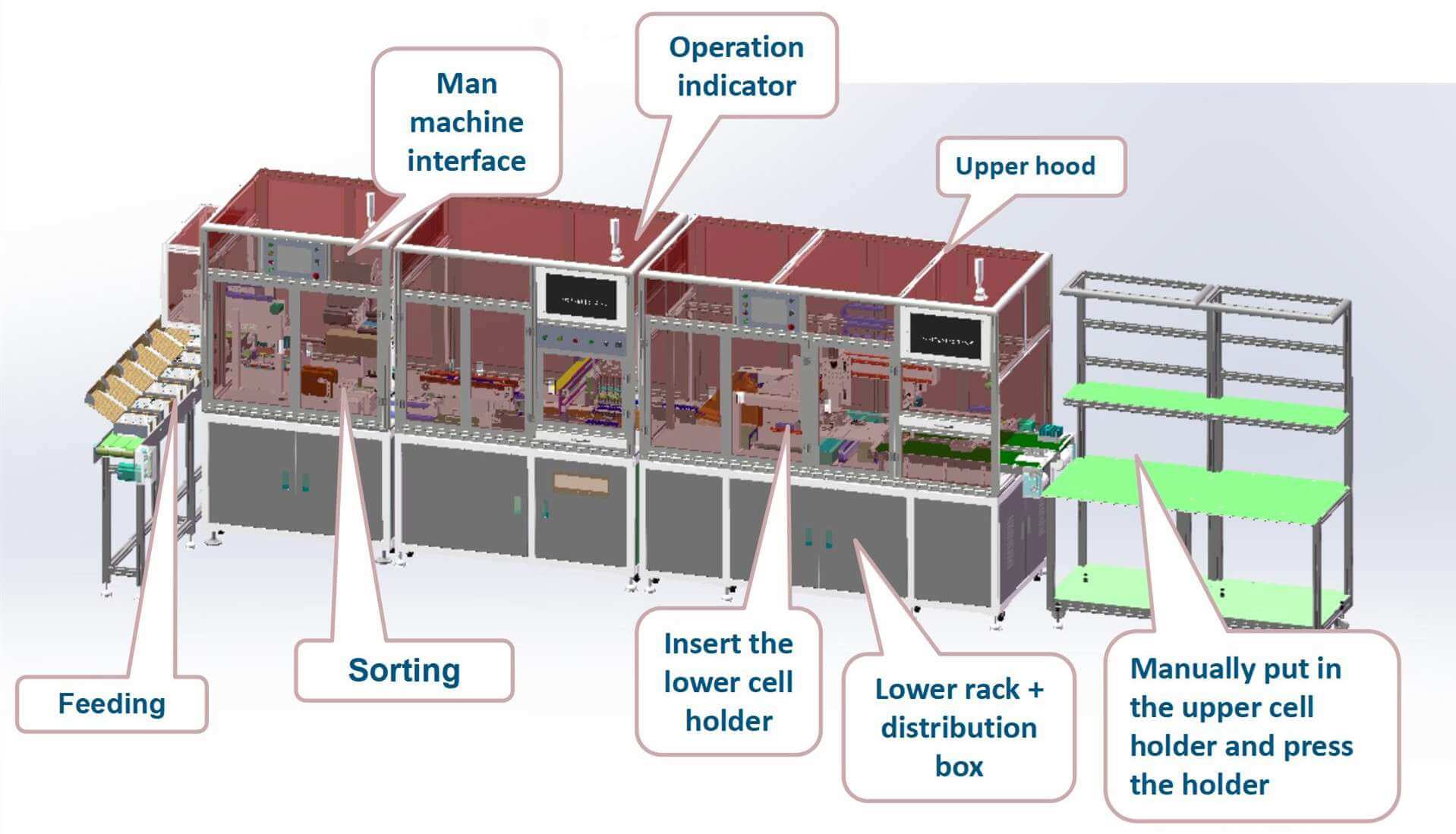

The assembly line has realized the automation of the whole process of battery and module loading, sorting, assembly, welding, testing and other links, with a stable rhythm. At this stage, the automatic detection system, automatic calibration and automatic processing system are added in the key steps of production, which completely uses the manipulator to replace the traditional manual complicated operation and ensure the stability of product quality. At present, the actual operation data show that the overall operation of the production line is safe and stable, the processing efficiency is high, and the quality of products is stable.

Main parameters of equipment:

Power specification: 220V / 380V 50Hz

Power: 5KW

Air pressure: 0.5-0.6 MPa

Planting rate: 90%

Output: 2000 ~ 3000 PCS / h

Ambient temperature: - 10 ℃ ~ 35 ℃,

Relative humidity 30% ~ 95%

Selection of main accessories |

||

1 |

测试仪 Tester |

HK 3561 |

2 |

触摸屏 Touch screen |

威伦通 Willonton |

3 |

导轨 Guide |

上银、TBI |

4 |

丝杆 Screw rod |

TBI |

5 |

气动元件 Pneumatic components |

SMC、亚德客(AirTAC) |

6 |

机械标准件 Mechanical standard parts |

米思米、怡合达 Mismi, yiheda |

7 |

步进电机 Stepper motor |

雷赛、斯马特尔 Reyes, smatel |

8 |

控制元件 Control element |

太控 Taikong |

9 |

PLC |

三菱、信捷、台达 Mitsubishi, Xinjie, Delta |

10 |

伺服电机 Servo motor |

三菱、松下 Mitsubishi, Panasonic |

11 |

传感器 Sensor |

欧姆龙、松下 Omron, Panasonic |

12 |

焊接电源 Welding power supply |

380V 逆变直流焊接电源 380V DC Welding Power Supply |

Appearance:

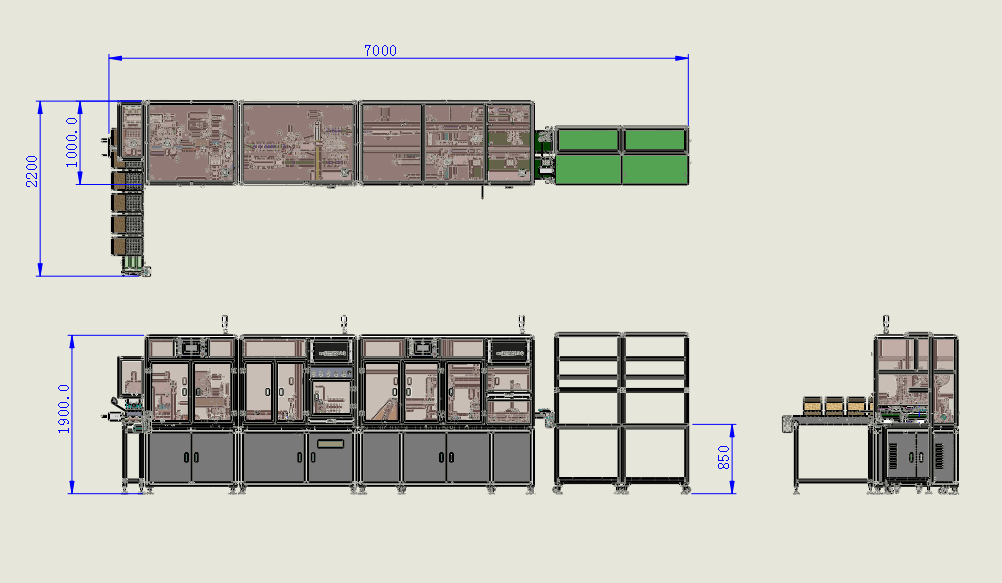

Size: L:7000mm*W:2200mm* H:1900mm* Height of operating table: 850mm

Equipment appearance description:

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com