products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

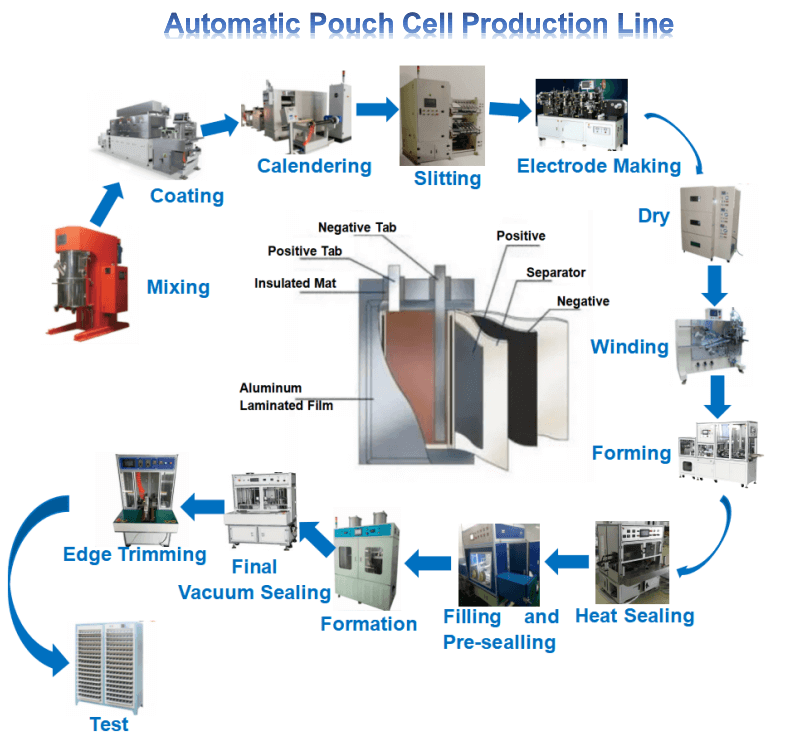

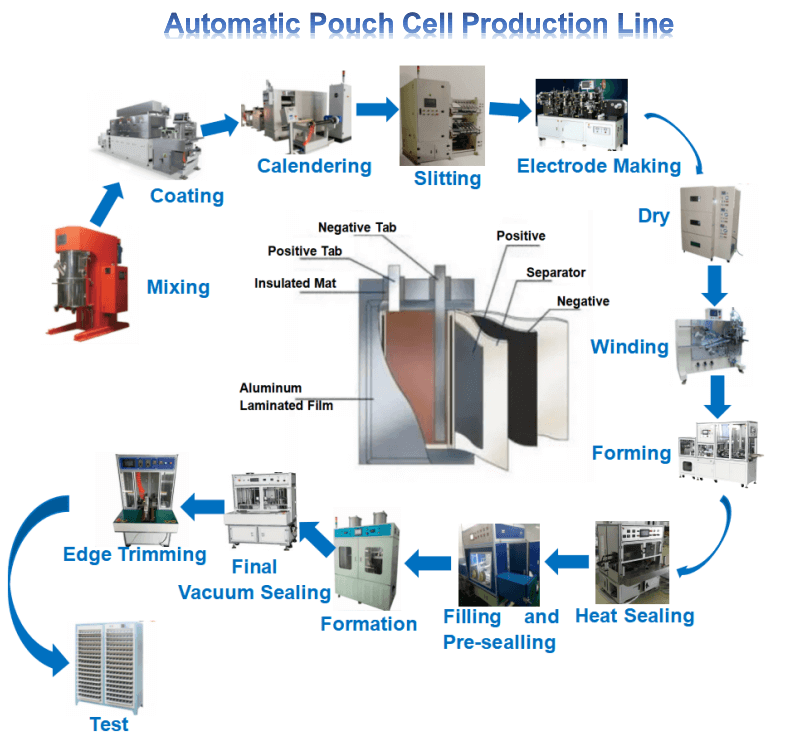

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

products

Automatic Electrolyte Filling Machine

Model Number:

TMAX-AFMY-200Dimension(L*W*H):

8000*1500*2400mmNet Weight:

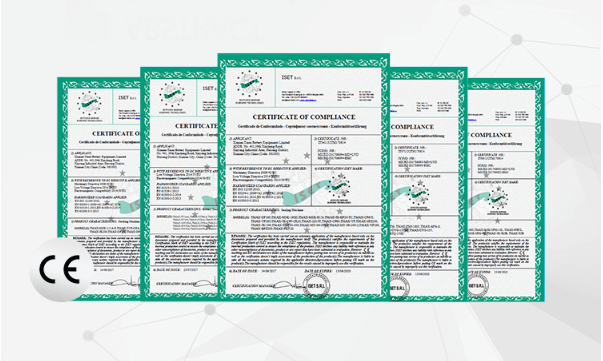

4000kgCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Product Details

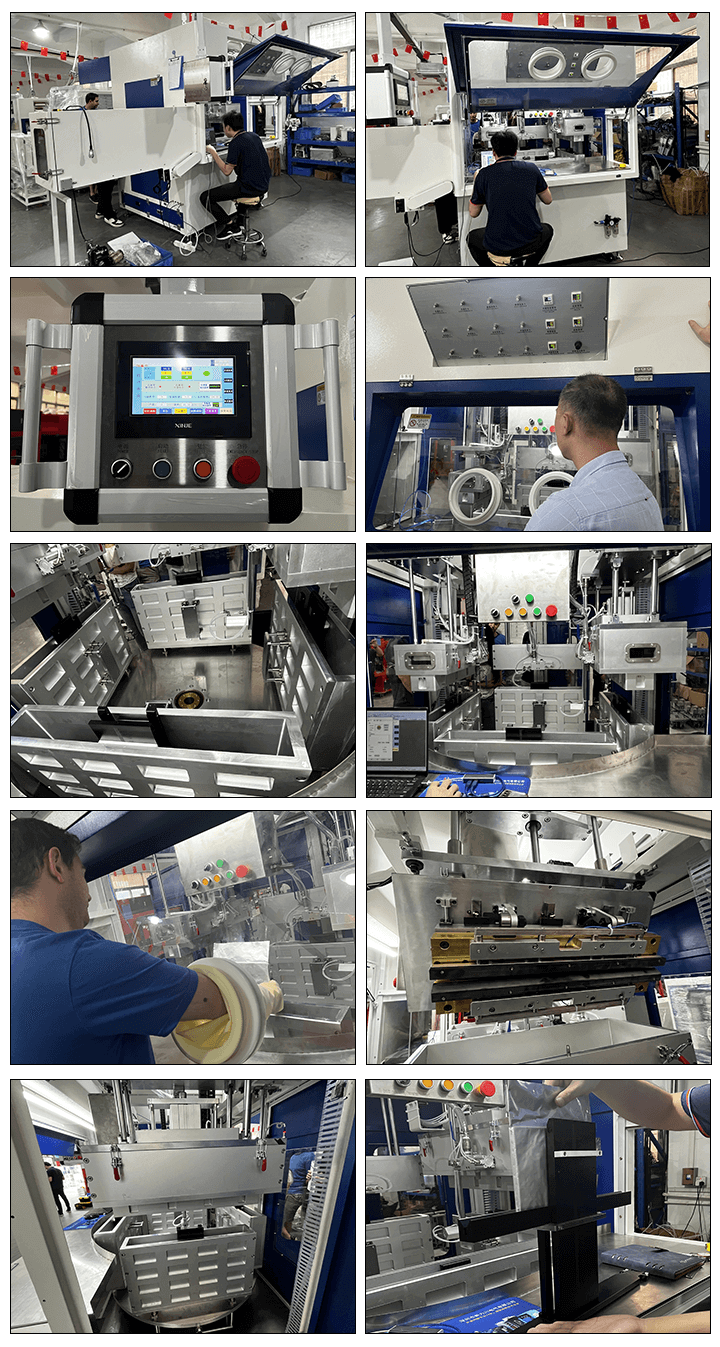

Automatic Electrolyte Filling Machine

SPECIFICATIONS

| Model | Automatic Battery Filling System TMAX-AFMY-200 | |

| Source voltage | AC220V, Single phase. Customized according country request | |

| Power | 10KW | |

| Warranty | One year limited warranty with lifetime support | |

| Compressed air | 0.6MPa | |

| Output | 6ppm, according to vacuum holding and sealing time | |

| Vacuum flow | 350M3/hour | |

| Suitable battery size | Length 130-285mm, Width 100-170mm, Thickness 8-11mm | |

| Structure configuration | Trough body | 3SET |

| Battery rotating mechanism | 1SET | |

| Automatic feeding mechanism | 1SET | |

| Weight before filling | 1SET | |

| Into the jig transfer institution | 1SET | |

| Pour institutions without electric pump | 1SET | |

| Vacuum holding box | 3SET | |

| Vacuum pre-sealing | 1SET | |

| Discharge transfer institution | 1SET | |

| Weight after filling | 1SET | |

| Automatic discharging device | 1SET | |

| Automatic receiving institutions | 2SET | |

| With PLC, Touch screen, | ||

| Driving motor | 2SET | |

| Project control system | 1SET | |

| CAM drive motor | 2SET | |

| Vacuum holding box | 1-99s can be set, with -95kpa vacuum degree | |

| Vacuum pre-sealing machine | Sealing stamp width : 8mm | |

| Sealing head length : 300mm | ||

| Sealing TEM : Max 260°C, adjustable | ||

| Sealing Head parallelism : ±0.02mm | ||

| Vacuum degree : -90KPa | ||

| Dimension (L*W*H) | 8000*1500*2400mm | |

| Weight | 4000kg | |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com