products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

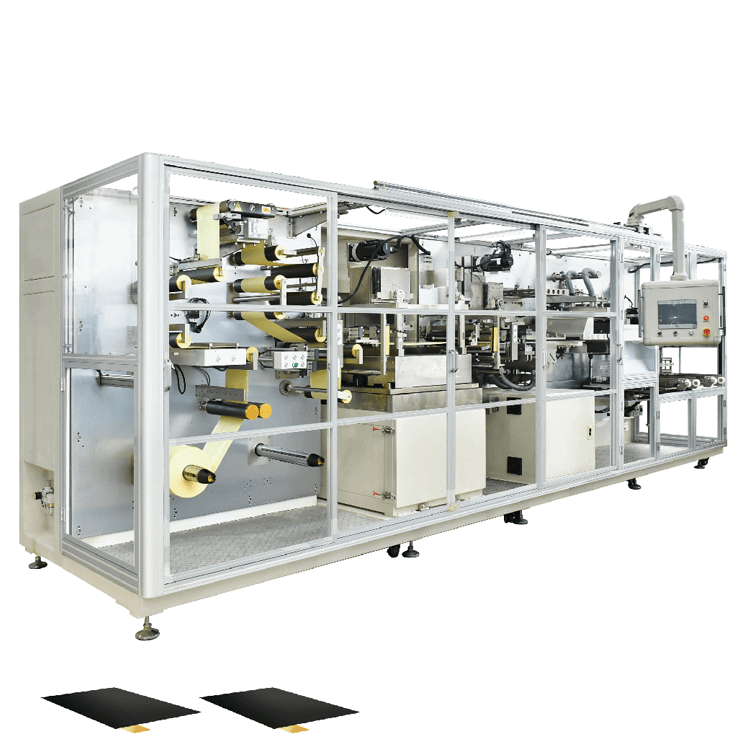

Automatic Hardware Stamping /Die-Cutting Machine for Prismatic or Pouch Cell Electrode Making

Model Number:

TMAX-CJZN-AC065Type:

AutomaticInput Power:

25KWDimension(L*W*H):

L5500xW1600xH2500Net Weight:

About 6000KgCompliance:

CE CertifiedWarranty:

One year limited warranty with lifetime technical supportShipping Port:

Xiamen PortPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

50 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

65000m3/h NMP Solvent Recovery System for Cathodic Coating Machine with Heat RecoveryNext:

Fully Automatic Tabs Welding Machine for Cell Production Line

Automatic Hardware Stamping /Die-Cutting Machine for Prismatic or Pouch Cell Electrode Making

Ⅰ、Equipment Introduction

1.1 Function Description

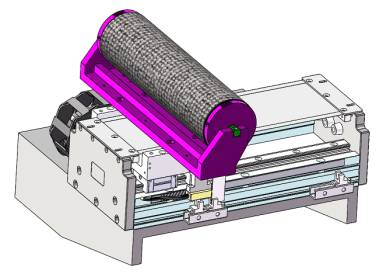

This machine is suitable for automatic forming of prismatic cell’s anode and cathode electrode(continuously coated with full tabs), using a metal mold punching method. Manually install the electrode coil onto the inflatable shaft of the equipment, and the equipment automatically unwinds and corrects deviation. The tension of the electrode film is controlled through a tension control system. After the electrode film undergoes EPC secondary correction, the appearance quality of the positive and negative sides of the electrode film is detected by CCD. The feeding mechanism pulls the electrode film to the punching and cutting position for punching and cutting the tabs and slice. The conveyor electrode film is transferred through a vacuum receiving belt, and the size of each electrode film is detected by CCD photography, The upper and lower surfaces of the electrode are treated with ion wind dust removal and iron removal, and defective products are automatically removed into the waste box. Qualified products are collected into the finished material box, and when the material box is full, it automatically connects to the material box conveyor line. Automatically replenish empty material boxes.

Product specification parameters

1.2 Incoming material specifications:

Spec Material |

Material |

Length mm |

Width mm |

Thickness um |

ID mm |

Max OD mm |

Cathode Electrode |

Sheet |

60~110 |

110~180 |

100~200 |

---- |

---- |

Anode Electrode |

Sheet |

60~110 |

110~180 |

80~180 |

---- |

---- |

Cathodic Tabs |

---- |

10~35 |

10~50 |

7~12 |

---- |

---- |

Anodic Tabs |

---- |

10~35 |

10~50 |

6~10 |

---- |

---- |

Separator |

Roll |

---- |

60~110 |

10~30 |

φ76.2 |

φ350 |

Tape |

Roll |

---- |

10~30 |

15~50 |

φ76.2 |

φ150 |

1.3 Incoming material requirements:

SN |

Item |

Specification |

1 |

Incoming width |

60~110mm(without tabs) |

2 |

Incoming material thickness |

60-200um |

3 |

Inner diameter of incoming coils |

3inch |

4 |

Outer diameter/weight of electrode incoming material |

≤700mm/≤300kg |

5 |

Coating method and damage requirements |

Continuous coating, with one side out of the tab and tab damage less than 0.5mm |

6 |

Uniformity of incoming material winding |

≤±2 mm |

7 |

Height of incoming wave edge |

≤0.5 mm |

8 |

Incoming coating width error |

≤±0.5 mm |

1.4 Equipment technical capabilities

Item |

Specification |

PPM |

≥ 220 PPM |

Burr size |

Lateral burr Va ≤ 12 μ M (Horizontal placement of the electrode: beyond the end face of the foil) Longitudinal burr Vb ≤ 12 μ M (vertical placement of the pole piece: the distance beyond the center of the longitudinal pole piece); |

CCD error detection rate |

≤0.5%(Using the number of electrode as the denominator) |

CCD miss detection rate |

≤0 |

Dimensional CCD detection accuracy |

±0.1mm |

Mold Life |

1. A single positive electrode ≥ 1.2 million times and a negative electrode ≥ 1.2 million times can repair the mold 10 times; |

Knife life |

1. A single positive electrode ≥ 1.2 million times and a negative electrode ≥ 1.2 million times can repair the mold 10 times; |

Slicing accuracy |

Width accuracy:+0.0/- 0.3 mm; Tab width accuracy,±0.15 mm; |

Material box receiving accuracy |

+/- 1mm |

Pass rate |

≥99%(Defects caused solely by the machine) |

Utilization rate |

≥98%(Defects caused solely by the machine) |

Ⅱ、Configuration Component Description

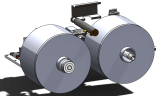

2.1 Automatic unwinding mechanism

2.2 Function:

Manual feeding, using an inflatable shaft to fix the pole coil material, and the feeding shaft is driven by a servo motor to actively unwind and automatically correct deviation;

2.3 Configuration and parameters:

1. It adopts an inflatable shaft for unwinding, and is driven by a servo motor and a precision reducer to actively unwind. The unwinding shaft is set in 3-inch increments, with a maximum compatible unwinding diameter of 700mm;

2. The unwinding correction adopts imported high sensitivity correction sensors, servo motors and screw drives, real-time correction, correction stroke+/-50mm, correction accuracy:+/-0.15mm;

3. The feeding height is 800mm, and the inflatable shaft is equipped with a sliding guide wheel, which is convenient for operators to operate;

4. Equipped with a laser line to calibrate the edge position of the pole roll, making it convenient for operators to align when replacing the material roll;

5. It has the function of calculating the diameter of the program coil. When the remaining material coil is at the set value, the program alarms to remind that the remaining material is insufficient and needs to be replaced;

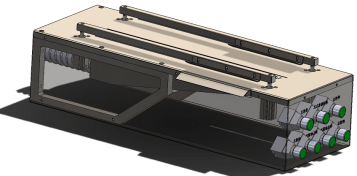

2.4 Manual tape connection platform

2.5 Function:

Used to compress the electrode strips at both ends and manually cut and stick the tape when replacing the electrode strip coil.

2.6 Configuration and parameters:

1. Use a cylinder to drive and tighten both ends of the pole piece before manually connecting the strip. The contact surface between the pressure block and the electrode strip is made of non-metallic material, which will not damage the strip path;

2. The tape receiving platform is equipped with scale markings for easy alignment and leveling during tape receiving;

3. The bottom of the cutting groove is equipped with a negative pressure dust removal mechanism, which can absorb the dust after cutting and avoid secondary pollution to the material belt;

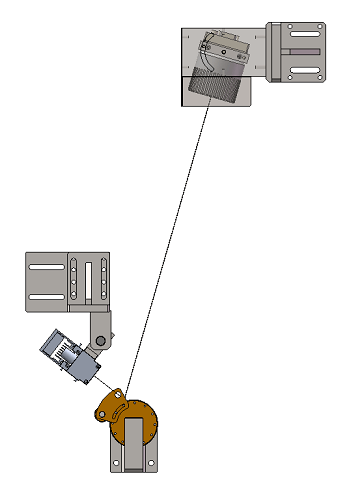

Ⅲ、Process correction mechanism

3.1 Function:

Using domestically renowned brand correctors to achieve real-time correction of the strip during operation, ensuring consistent strip position during continuous unwinding;

3.2 Configuration and parameters:

1. Adopting a well-known brand deviation correction system in the industry, real-time detection, control, and display are carried out to correct the horizontal deviation of the edge of the electrode coating during the strip moving process in real time;

2. Deviation correction stroke X, Y:+/-10, R:+/-5 °;

3. Deviation correction accuracy:+/-0.1mm;

4. Correction width:≥120mm;

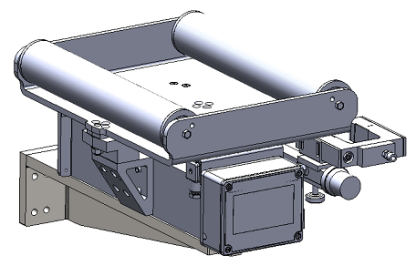

Ⅳ.Tension mechanism

4.1 Function:

The structure adopts a low friction cylinder with a swing rod, and is controlled by an electrical proportional valve to achieve constant tension of the belt. The tension size can be set;

4.2 Configuration and parameters:

1. Adopting a low friction cylinder and swing rod structure, controlled by an electrical proportional valve to achieve closed-loop constant tension;

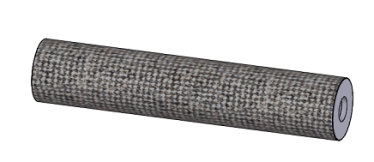

2. The roller adopts carbon fiber roller surface polishing treatment, equipped with high speed low friction bearings, to reduce belt resistance;;

3. Belt tension: 0-200N, tension fluctuation:+/-5%

Ⅴ、Electrode plate over roll

5.1 Function:

Used for transitional conveying of the strip during the unwinding process of electrode coil materials;

5.2 Configuration and parameters:

1. The electrode roller adopts aluminum+brown hard oxidation/carbon fiber coated hardening resin, with a surface roughness better than Ra0.6. All rollers undergo dynamic and static balance testing;

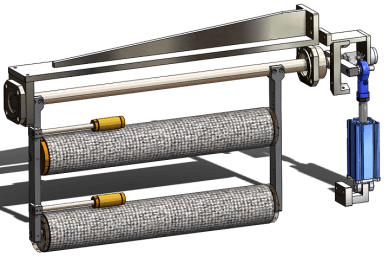

Ⅵ. Electrode sheet cache

6.1 Function:

When the mold is slicing, the cache mechanism absorbs the strip released during this time period, achieving the function of continuous unwinding;

6.2 Configuration and parameters:

1. Use servo module to actively cache, ensuring continuous unwinding during die cutting, stabilizing tension, improving production efficiency, and ensuring drawing accuracy;

2. The drum is made of carbon fiber, reducing the inertia moment of the storage drum, ensuring the accuracy of material pulling and equipment stability;

3. Cache electrode length: ≥ 300mm

4. Positioning accuracy: ± 0.1mm

Ⅶ、Defect detection institutions

7.1 Function:

Perform defect detection on the positive and negative surfaces of the electrode, output NG signals, and record defective product data;

7.2 Configuration and parameters:

1. Use a line scanning camera to detect surface defects on the front and back sides of the electrode, record defective product data, and save it to a computer;

2. Pixel accuracy:+/-0.05mm

3. Minimum detection area:≤0.5mm²

4. Error rate:≤0.5%

5. Leakage rate: 0

6. The corresponding parameter settings can be saved for different types of electrodes, and the detection images can be viewed on the display screen;

Ⅷ、Product Image:

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588