products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

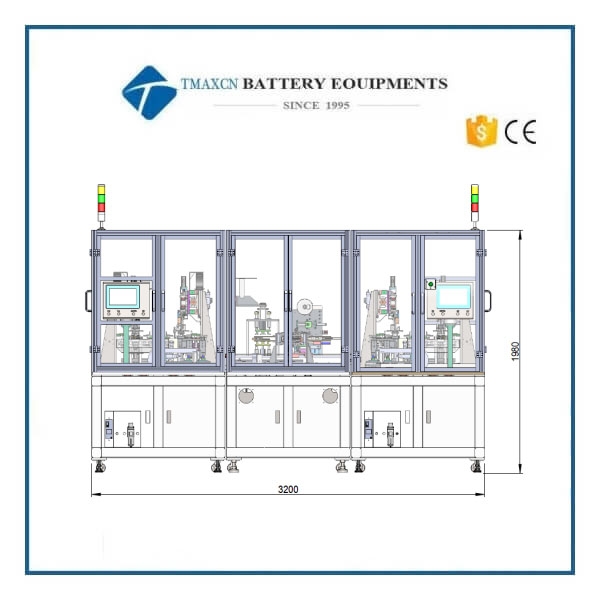

Automatic Z-shaped Dual-Workstation Stacking Machine for Prismatic Lithium-ion Power Battery Cells

Model Number:

TMAX-DS150Type:

Automatic StackingCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportShipping Port:

Xiamen PortDelivery Time:

50 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Single Workstation Stacking Machine for Lithium Battery Electrode MakingNext:

9000 m³/h NMP Exhaust Gas Treatment System for Lithium Battery Production

Automatic Z-shaped Dual-Workstation Stacking Machine for Prismatic Lithium-ion Power Battery Cells

1. Equipment Introduction

1.1 Equipment Overview

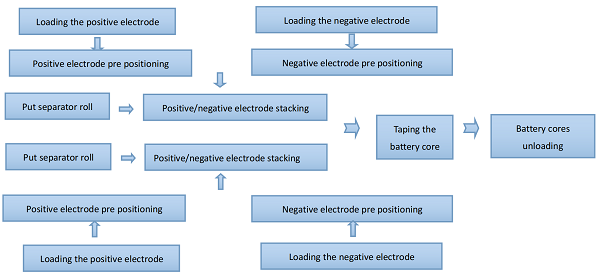

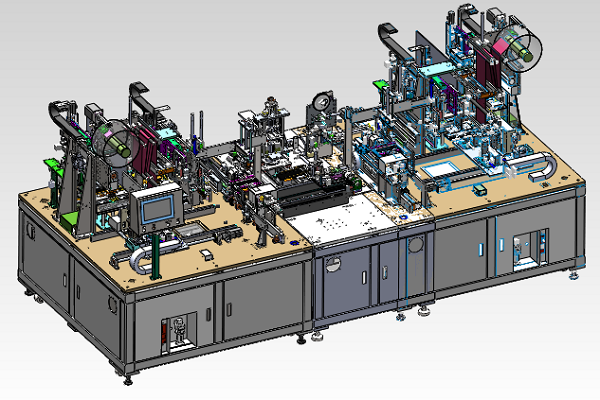

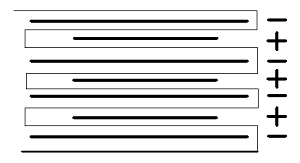

This equipment is mainly used for the Z-shaped stacking process of prismatic lithium-ion power battery cells.

1.2 Workflow

The separator is actively unwound, fed through the tension control mechanism, and guided smoothly onto the stacking platform. This platform then moves back and forth to position the separator, setting the stage for electrode placement.

The stacking process starts with positive and negative electrode sheets: two robotic suction arms retrieve these sheets from their respective left-side feed boxes, precisely align them, and stack them onto the platform. Once stacking is complete, the separator is cut to length. A robotic arm then transfers the cell to the taping station, where taping is done automatically—all while the next cell begins stacking seamlessly, ensuring continuous operation.

1.3 Equipment Features

· 1.3.1 Separator: Active unwinding; tension control; deviation correction; static elimination; alignment accuracy ±0.5mm.

· 1.3.2 High precision: Mechanical positioning of electrode sheets ensures total stacking accuracy within ±0.3mm.

· 1.3.3 High efficiency: Single-side stacking speed reaches 1.2s–1.5s/Pcs depending on sheet size.

· 1.3.4 Dust protection: Effective dust protection mechanisms are installed at material box and pre-alignment positions.

· 1.3.5 Reliability: All high-precision and frequently moving modules are fixed with positioning pins.

· 1.3.6 Multi-sheet & missed sheet protection: Equipped with anti-multiple sheet mechanism and detection system to prevent stacking errors.

· 1.3.7 Tab inspection: Prevents inclusion of faulty electrode sheets with bent or missing tabs.

· 1.3.8 Stacked-cell discharge

2. Standard Components

No. |

Component Name |

Qty/Set |

Description |

1 |

Automatic Material Feeder |

4 |

Special insert-type feed boxes; 2 sets for both positive and negative sheets |

2 |

Auxiliary Feeding Unit |

4 |

Brushes, vibration, air blow, dust removal, anti-multi-sheet |

3 |

Lifting Unit for Feeding |

2 |

Ensures reliable sheet pickup; alarms for sheet shortage |

4 |

Separator Tension Mechanism |

2 |

Active unwinding with constant tension |

4.1 |

Separator Deviation Correction |

2 |

Roll deviation correction |

5 |

Pre-positioning Module |

4 |

Mechanical positioning with dust suction system |

5.1 |

Multi-sheet Detection |

4 |

Ultrasonic thickness detection |

6 |

Stacking Robot Arm |

4 |

Servo-driven, reliable sheet pickup and placement |

7 |

Suction Cup Assembly |

8 |

2 vacuum nozzles + 2 suction plates for each type |

8 |

Stacking Platform |

2 |

Servo-driven with ball screw linear motion |

9 |

Cell Transfer Arm |

1 |

Automatically transfers cells |

10 |

Separator Cutting Unit |

2 |

Thermal cutters; < 3mm distance to cell edge |

11 |

Side Taping Unit |

1 |

Configurable for tab areas and four sides |

12 |

Cell Discharge Mechanism |

1 |

Stacked discharge |

13 |

Control Panel |

1 |

Touch screen with emergency/power buttons |

14 |

Internal Control System |

1 |

All electrical/pneumatic inside enclosure |

15 |

Frame Panel |

2 |

Color: computer white |

16 |

Dustproof Cover |

1 |

Aluminum alloy + acrylic, with safety interlock |

17 |

Dust Collection |

1 |

Blower system at feed and pre-alignment stations |

18 |

Vacuum System |

/ |

Provided by manufacturer |

3. Material Specifications

3.1 Material Dimensions

Material |

Form |

Length (mm) |

Width (mm) |

Thickness (um) |

ID (mm) |

Max OD (mm) |

Cathode |

Sheet |

50-160 |

30-150 |

100-280 |

- |

- |

Anode |

Sheet |

50-160 |

30-150 |

80-280 |

- |

- |

Cathode Tab |

- |

10-40 |

10-60 |

12-30 |

- |

- |

Anode Tab |

- |

10-40 |

10-60 |

6-20 |

- |

- |

Separator |

Roll |

- |

60-250 |

16-45 |

76.2 |

300 |

Tape |

Roll |

20-80 |

10-20 |

100-200 |

76.2 |

150 |

Notes:

1. Electrode length refers to tab direction only (excluding tab).

2. No obvious powder loss, edge waviness or burrs < 15um; punching tolerance < 0.2mm.

3. No obvious warping, deformation or adhesion.

4. Separator serpentine deviation: ±0.2mm/1000mm.

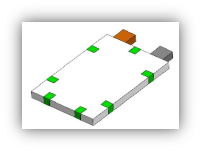

3.2 Cell Specifications

Item |

Specification |

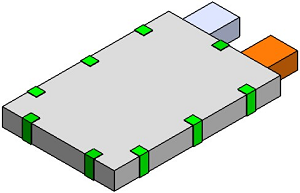

Cell Diagram |

||

Length L |

50-160 mm |

|

||

Width W |

30-150 mm |

|||

Thickness T |

3-20 mm |

|||

Tab Exposure L1 |

6-30 mm |

|||

Tab Orientation |

Opposite |

|||

L + L1 (tab side limit) |

≤200 mm |

|||

|

|

|||

4. Technical Parameters

Item |

Value |

Single-side stacking time |

1.2 - 1.5s |

Auxiliary time per cell |

≤10s |

Sheet-to-separator accuracy (adjacent) |

±0.5mm |

Separator edge alignment |

±0.4mm |

Sheet-to-sheet alignment |

±0.3mm |

Overall stack accuracy |

±0.3mm |

Stackable layers |

Within thickness limits |

Discharge method |

Cell stack discharge |

Machine utilization rate |

≥95% (machine-side) |

Qualification rate |

≥98% (machine-side) |

5. Standard Components List

No. |

Component |

Brand |

1 |

Cylinder |

AIRTAC |

2 |

Linear Rail |

DINGHAN/HIWIN |

3 |

Ball Screw |

TBI/HIWIN |

4 |

PLC |

OMRON |

6. Format Change Parts List

No. |

Module |

Part Name |

Unit |

Qty |

Notes |

1 |

Electrode box |

Movable panel |

pcs |

8 |

Adjustable range for feeder box, pre-alignment, suction |

2 |

Pre-position |

Adjustment plate |

pcs |

4 |

|

3 |

Stack arm |

Suction plate |

pcs |

4 |

|

4 |

Stack platform |

Compression plate |

pcs |

8 |

|

5 |

Cell support plate |

pcs |

2 |

||

6 |

Discharge |

Bracket |

pcs |

4 |

|

7 |

Tape Unit |

- |

set |

1 |

|

8 |

Others |

|

|

|

|

7. Wearing Parts List

No. |

Name |

Model |

Manufacturer |

Remarks |

1 |

Nozzle |

Custom |

Machined Part |

Daily cleaning required |

2 |

Plate 1 |

Custom |

Machined Part |

10-day lead time |

3 |

Plate 2 |

Custom |

Machined Part |

10-day lead time |

4 |

Vacuum Filter |

VFD-3-06 |

CHELIC |

Weekly cleaning required |

5 |

Vacuum Generator |

VAB-0706 |

CHELIC |

Weekly cleaning required |

6 |

Foam |

- |

Consumable |

Protects contact surface with cell |

7 |

Teflon |

- |

Consumable |

Protects contact surface with electrode |

8. Delivery List

No. |

Item |

Qty |

Unit |

Remarks |

1 |

Automatic Stacker |

1 |

unit |

Model for acceptance |

2 |

Solenoid Valve |

1 |

pcs |

Spare part |

3 |

Sensor |

2 |

pcs |

Spare parts |

4 |

Tools |

1 |

set |

Tool kit |

5 |

Delivery Specification |

1 |

copy |

After signing; return 1 copy |

6 |

Quality Inspection Report |

1 |

copy |

Provided on delivery |

7 |

User Manual |

1 |

copy |

Provided on delivery |

8 |

Spare Parts List |

1 |

set |

Delivered with equipment |

9 |

Format Change Materials |

1 |

set |

Delivered with equipment |

10 |

Wearing Parts List |

1 |

copy |

Includes models and part numbers |

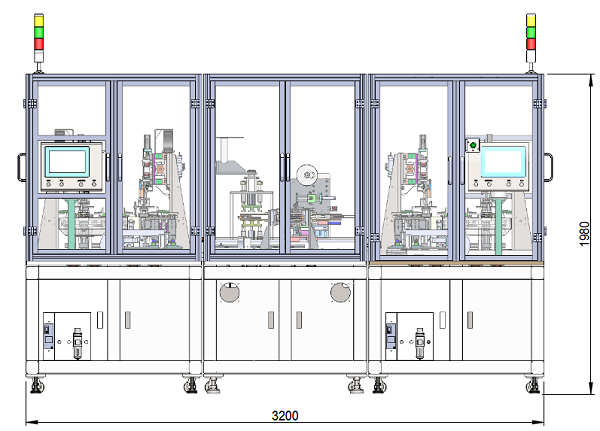

9. General Machine Specifications & Diagram

Item |

Specification |

Machine Size |

W3870 x L1950 x H1900mm (final design size) |

Weight/Floor Load |

~2200KG; >450Kg/m^2 |

Power Supply |

AC220V ±10%, Single Phase, 7KW, 50Hz |

Compressed Air |

0.5~0.7MPa, 200L/min, dry air |

Temperature/Humidity |

5~35℃; 5~55% |

Air/Dust |

No corrosive/toxic gas; no conductive dust |

Magnetic/Vibration |

No magnetic field interference or strong vibrations |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com