Site Blog

contact us

- If you have questions, please contact us, all questions will be answered

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

hot products

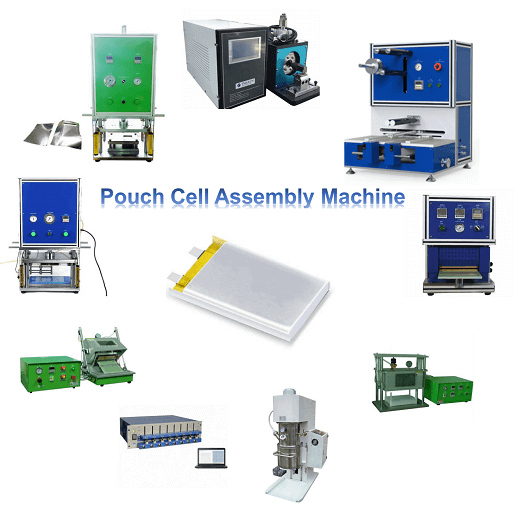

"Pouch Cell Lab Line" refers to laboratory production lines designed for manufacturing flexible pouch cells, which are a type of lithium-ion battery. These lines offer several advantages over traditional production lines used for manufacturing rigid-cased batteries:

Flexibility and Customization: Pouch Cell Assembly line can quickly adapt to different specifications and designs of flexible pouch cells. Their configurations are more flexible compared to traditional production lines, allowing for the production of batteries in various sizes and shapes to meet specific requirements.

Lightweight Design: Flexible pouch cells are inherently lighter and thinner than rigid-cased batteries, and Pouch Cell Lab Lines can further reduce the weight and volume of batteries produced. This makes flexible pouch cells particularly suitable for applications such as portable electronic devices and electric vehicles.

High Energy Density: Without the external constraint of a rigid casing, flexible pouch cells can utilize space more efficiently, achieving higher energy densities. This results in batteries with longer operating times and higher energy outputs for various applications.

Ease of Integration: Batteries manufactured using Pouch Cell Lab Lines are easier to integrate into other systems, such as battery packs for electric vehicles and energy storage systems. Their flexible design allows batteries to adapt to different installation spaces and shape requirements.

Electric Vehicle (EV) Manufacturers: Many electric vehicle manufacturers utilize flexible pouch cells in their battery packs due to their lightweight design, high energy density, and ease of integration. Companies such as Tesla, Nissan, and General Motors incorporate flexible pouch cells into their electric vehicle batteries.

Hybrid Electric Vehicle (HEV) and Plug-in Hybrid Electric Vehicle (PHEV) Manufacturers: Manufacturers of hybrid and plug-in hybrid vehicles also utilize flexible pouch cells in their battery packs to achieve a balance between performance, energy density, and cost. Companies like Toyota, Honda, and BMW use flexible pouch cells in their hybrid vehicle batteries.

Overall, Pouch Cell Lab Lines offer significant advantages in terms of flexibility, cost-effectiveness, and performance, making them increasingly popular in automotive production for various types of vehicles.

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com