products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Cutting Machine

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

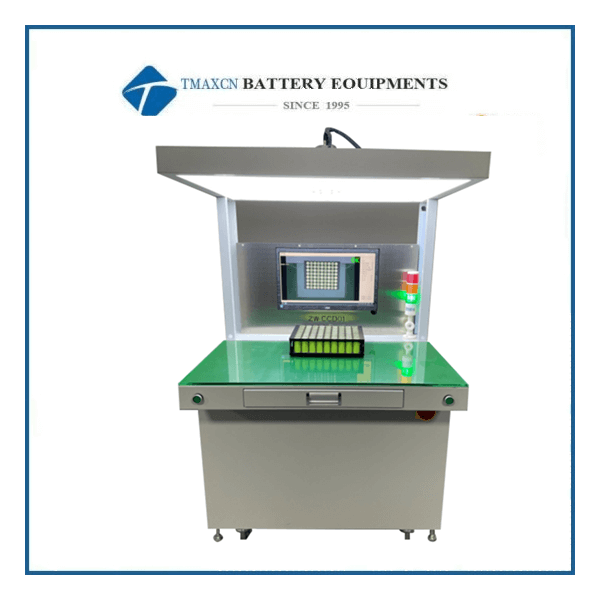

CCD Visual Inspection Equipment for Positive and Negative Battery Electrode Detection

Model Number:

TMAX-CCDType:

AutomaticInput Power:

500WDimension(L*W*H):

960 * 950 * 1800mmNet Weight:

150kgCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPlace of Origin:

ChinaPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13174506016

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

11 Channels 18650&26650&32650 Common Use Accepted Battery Cell Sorting MachineNext:

100V 120A 18650 Battery Pack Comprehensive Tester Multi Functional Test Equipment

CCD Visual Inspection Equipment for Positive and Negative Battery Electrode Detection

Ⅰ、Introduction

CCD vision detection equipment, in fact, means that through the machine vision product CCD image sensor will be taken into an image signal, transmitted to a dedicated image processing system, according to the distribution of pixels and brightness, color, and other information, a detection device that Converts Signals Into Digital Signals; an image system performs various operations on these signals to extract the characteristics of the target and then control the action of equipment in the field according to the results of discrimination. CCD vision detection equipment can replace the human eye to do measurement and judgment, is used in production, assembly or packaging of valuable equipment. It has higher efficiency and accuracy in detecting whether the batteries are correctly placed in series-parallel positive and negative electrodes and in detecting products with defects in spot welding.

Ⅱ、Configuration parameter

Equipment Power: 600W, 220V AC input, 50Hz.

Function of the device: for the cylindrical cell, the positive and negative electrode data are collected by camera, the number of positive and negative electrodes and the position information of positive and negative electrodes are compared with the sample, the result (NG or OK) is quickly analyzed, and the position of Ng is marked, in order to confirm the positive and negative electrodes of the battery before entering spot welding, and prevent the bad caused by the wrong position of the positive and negative electrodes.

Core Range: cylindrical core 14430/14500/18500/18650/21700/26650/32650, etc.

Suitable Detection Range: 400 * 300 mm, if more customized

After sample collection, 360-degree rotation position can be detected

Parameters set, one-click start detection mode

Simple function setting, easy to understand and operate, no need for on-site training

The Industrial Control Computer supports the function of sudden power failure, and the database works normally.

Local database, mainly for cylindrical cell positive and negative electrode data, other categories are not compatible.

DETECTION SPEED: 100PCS/1.5 S

TESTING ACCURACY: the cell is not deformed or rusty, 100%

Mass storage product parameters, call out parameters direct detection

Ⅲ、System configuration

Hikvision |

6 million HD industrial camera |

|

|

Hikvision |

Ten million class industrial lens |

|

|

recognition system |

Independent research and development |

|

|

IPC |

Intel original i7 processor |

|

Intel original industrial control motherboard |

|

Genuine Windows 7 industrial control system |

Allowable material movement speed |

1.5M/min |

Display pixel |

1920*1080 |

Camera width |

400*300mm |

DC power supply |

Dual Taiwan original Mingwei power supply |

monitor |

19 inch display |

LED |

For battery |

![]()

ru

ru

Iris@tmaxcn.com

Iris@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13174506016

+86 13174506016