products categories

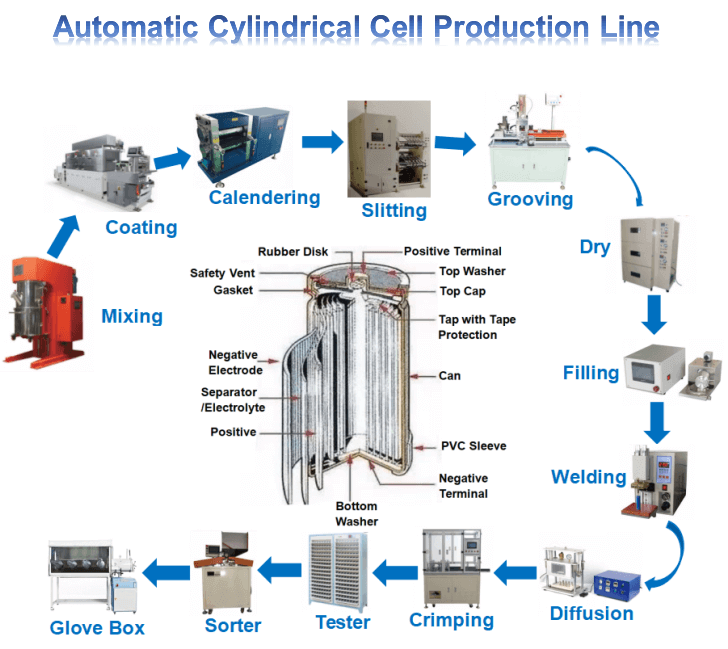

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Cylindrical Battery Sealing Crimping Machine Glove Box Compatible

Model Number:

TMAX-YZFK-18ANet Weight:

800lbsCompliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Cylindrical Battery Sealing Crimping Machine Glove Box Compatible

1. Equipment Description

1.1 Equipment Name:

Automatic Sealing Machine Inside Glove Box

1.2 Product Function:

This equipment is specially developed for the cylindrical battery sealing process. It is a high-precision battery sealing machine, mainly used for the sealing of cylindrical batteries. The machine can complete pre-sealing, secondary sealing, and tertiary sealing in one operation.

It has stable and reliable performance, high sealing efficiency, good product consistency, simple operation, and easy maintenance. It is suitable for small-scale battery production.

1.3 Working Principle:

The working principle is that the transmission feeding groove drives the batteries for automatic feeding. Under the control of an electrical program, a cylinder pushes the batteries forward. Step-by-step feeding pushes the batteries sequentially into the mold.

The upper sealing air–hydraulic booster cylinder applies sealing force, generating huge pressure to compress the battery case and cover to the required process dimensions, thereby achieving the purpose of battery sealing.

2. Basic Configuration

l Airtac cylinders and Airtac electrical components

l Omron electrical control system

l SMC sensors

l Oil-resistant booster cylinder 5T

l Omron power supply

l Chint electric components

l Safety light curtain protection device

3. Process Parameters

l Sealing range: Type 14 / 18 / 21

l Sealing speed: 25–30 pcs/min, adjustable speed

l Working pressure: 3T

l Total machine power: 250 W, 220V / 50Hz

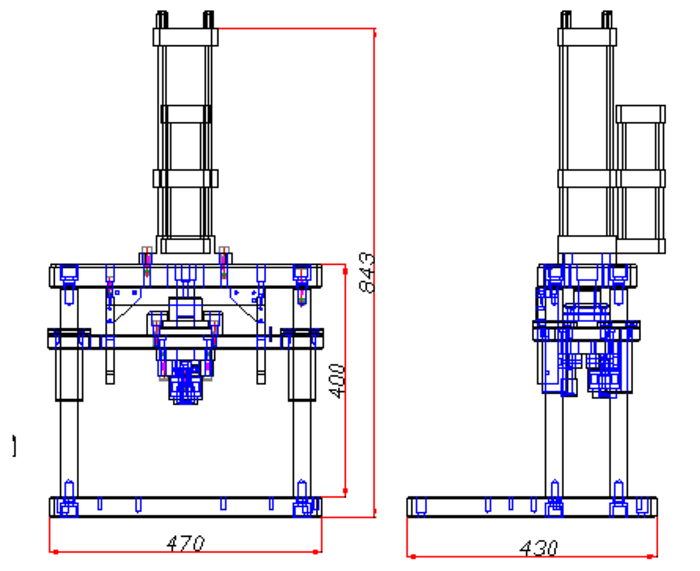

l Overall dimensions: 830 (L) × 430 (W) × 900 (H) mm

l Sealing steps: Pre-sealing, secondary sealing, tertiary sealing completed in one linkage operation

l Sealing pressure airtightness test: Can reach above 2 MPa

l Total equipment weight: 250 kg

l Working air pressure: Must reach ≥0.4 MPa for the equipment to start effectively; if lower than 0.4 MPa, the equipment will automatically alarm and stop

l Upper and lower sealing molds: Made of imported wear-resistant oil steel, with hardness after treatment reaching HRC 60–62

4. Appearance Layout

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com