products categories

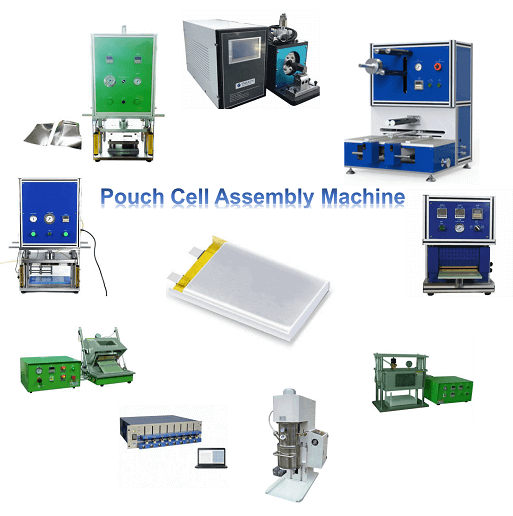

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

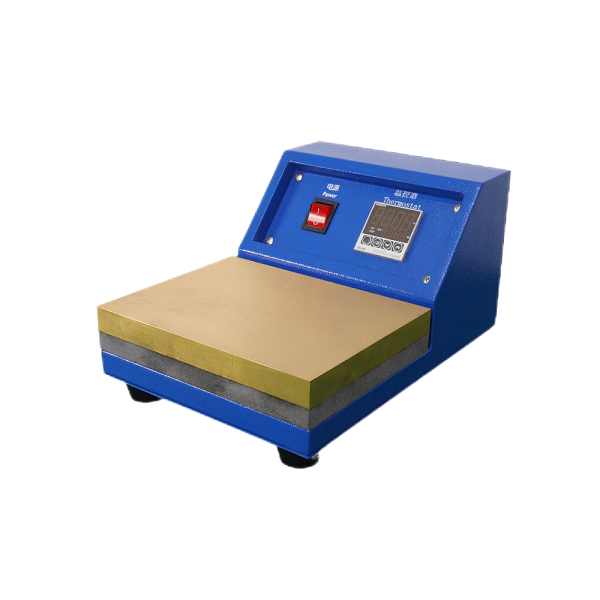

Edge Ironing Machine for Pouch Battery Preparation

Model Number:

TMAX-TP200Input Power:

250WDimension(L*W*H):

280x 200x 165mmNet Weight:

20kgCompliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportPlace of Origin:

Fujian, China (Mainland)MOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Compact Vacuum Sealing Machine with Integrated Temperature and Pressure Control in One Unit for Preparing Pouch BatteryNext:

Edge Folding Machine for Pouch Battery Preparation

Edge Ironing Machine for Pouch Battery Preparation

Application

The TMAX-TP200 Pouch Cell Edge Ironing Machine is designed for edge ironing and reshaping of pouch-type lithium ion battery aluminum-laminated films after folding. It ensures a neat and flat appearance, enhancing the aesthetic and structural quality of the battery edges.

Key Features

· Imported temperature controller (Omron) enables precise control of heating plate temperature, adjustable from room temperature to 250°C.

· Safe anti-scalding design, with temperature adjustable via digital control panel.

· Copper heating platform, offering excellent heat conductivity, energy efficiency, and high work efficiency.

· Compatible with various pouch cell sizes, providing flexible application.

· Attractive design, featuring three-dimensional sheet metal structure for a clean, modern look.

· Compact machine size, producing uniform and smooth ironing results with high visual quality.

Technical Specifications

Parameter |

Specification |

Ironing Platform Size |

L200mm × W155mm |

Temperature Range |

0–250°C ±2°C (Adjustable, digital display) |

Heating Element Power |

250W |

Power Supply |

AC220V / 50Hz |

Total Power Consumption |

1.5KW |

Machine Dimensions |

L280mm × W200mm × H165mm |

Machine Weight |

20kg |

Heating System |

Copper heating platform |

Key Electrical Components |

Omron temperature controller & solid-state relay |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com