products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

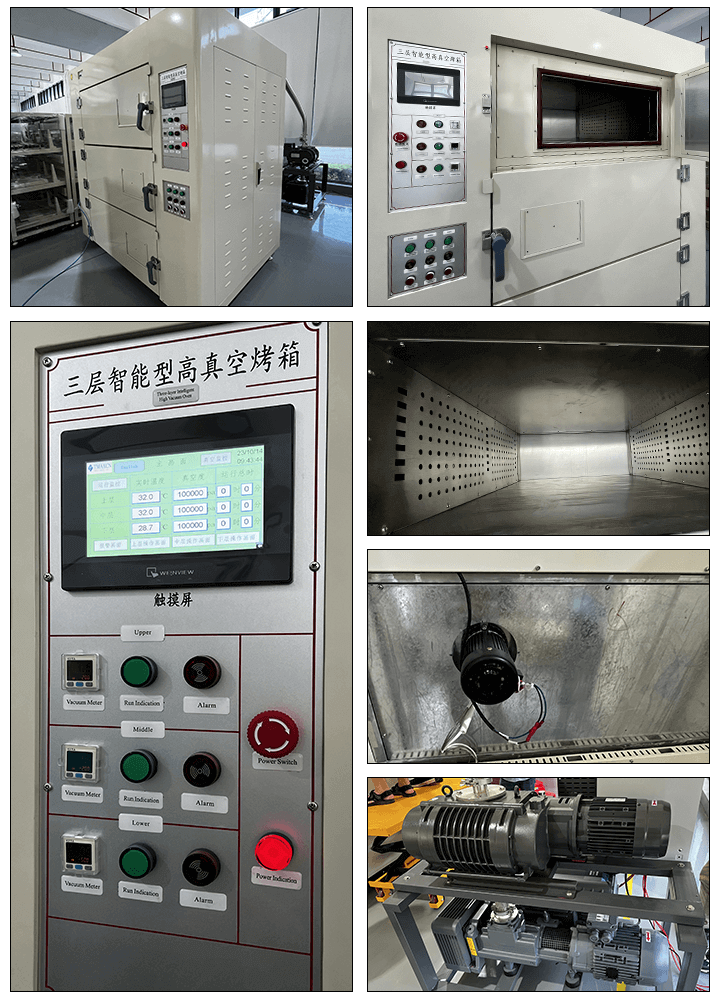

Electrode Sheet Baking Machine Three Layers Vacuum Drying Oven For Battery Making Machine

Model Number:

TMAX-JK-ZKHX-A3Input Power:

4.5KW*3Dimension(L*W*H):

height:300 mm width: 800 mm depth: 600 mm*3 layersNet Weight:

700kgCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Laboratory Small Electrolyte Filling Machine for Li-ion BatteryNext:

Lab 18650 26650 21700 4680 32650 AA AAA Cylindrical Cell Grooving Machine Beading Machine

Electrode Sheet Baking Machine Three Layers Vacuum Drying Oven For Battery Making Machine

This oven is mainly used with square vacuum chamber, can make full use of space. Pumping speed fast and efficient, high vacuum, easy to operate. Toughened bulletproof double glass observation window clearly the object of the working chamber. The tightness of the box can be adjusted, the overall shape of the silicon rubber gasket to ensure a high vacuum chamber. This product is suitable for the production process of electronic products off the bubble, dehydration, hardening and drying after cleaning treatment under vacuum heat treatment, the LED optical original lithium battery, and battery electrode,and so on, has a high reputation in the electric industry field.

Parameter |

performance |

Description/model |

Battery special vacuum oven |

Workroom size |

height:300mm width: 800mm depth: 600mm*3 layers |

Outline size |

height:1850mm width:1420 mm depth: 890mm |

Working temperature |

room temperature :+15℃~200℃ |

The speed of risingtemperatur |

not more than 120 minutes when rising to the max.temperature |

Heating power |

4.5KW*3 |

Electrical supply |

Three- phases380V |

Outside material |

Cold-rolled plate,spay platics |

Color |

According to the customer’s color standard |

Working room material |

SUS304 stainless steel plate |

Stratified |

Multi |

Layer floor |

2 layer mesh partition / layer |

Exhaust connection |

back |

Open method |

Single-door, flexible double steel glass, with over pressure protection function |

Sealing ring |

silicone rubber ring with high temperature resistance, no connector |

Temperature instrumentation |

digital temperature controller |

Temperature control mode |

PID regulator |

Temperature accuracy |

±1℃ |

Temperature uniformity |

±5℃ |

Temperature Sensor |

PT100 |

Timing Control |

10 -hour timer, the alarm buzzer |

Over temperature protection |

over-temperature protection,when over the temperature, cut off the heating power and alarm buzzer |

Heating device |

Heating wire |

Vacuum |

100Pa, 6 hours pointer does not move ,12 hours to keep 98% , 24 hours to keep 95% |

Gas leakage |

≤300pa/h |

Remark |

three studios to work independently, independent heating, three sets of temperature control system, can work alone, can also work at the same time.Manual control vacuum switch, vacuum- sealed well when the power cut. The vacuum chamber can be individually, separately add nitrogen, without disturbing each other |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com