products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

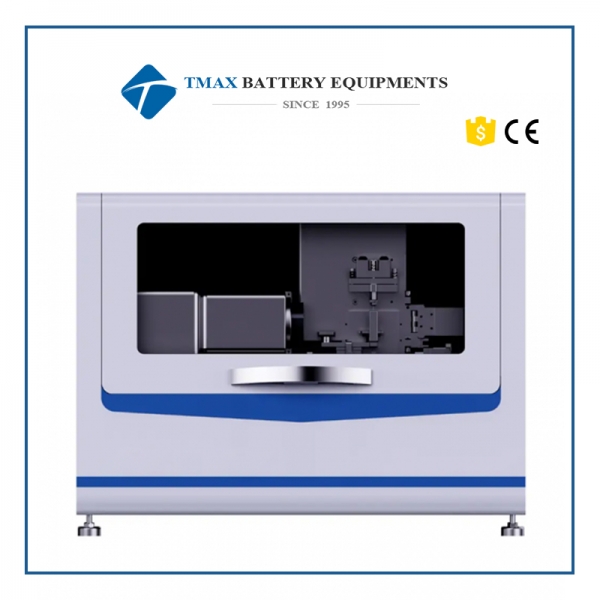

Electrolyte Wetting Testing System

Model Number:

TMAX-EWS/ETS/CHTCompliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lithium Battery Electrode Sheet Resistance TesterNext:

In-Situ Cell Swelling Testing System

Electrolyte Wetting Testing System

Introduction

Combining the visual acquisition system and the capillary action of the electrolyte to evaluate the wetting differences of different electrodes, electrolytes, diaphragm formulations and processes.

Characteristic

1. Based on the principle of capillary diffusion of electrolyte in the electrodes and separators, quantitatively evaluate the difference in electrolyte infiltration;

2. Equipped with high-precision mechanical control and visual acquisition system, the test is stable and efficient;

3. Suitable for evaluation of infiltration differences of different electrodes, electrolytes, separator formulas and processes;

4. Characterize the infiltration rate of electrolyte in the sample in real time.

Applications

1. Electrolyte: Performance Evaluation

2. Electrode: Consistency Assessment

3. Optimization of material: Electrode Surface Treatment Processes

Description

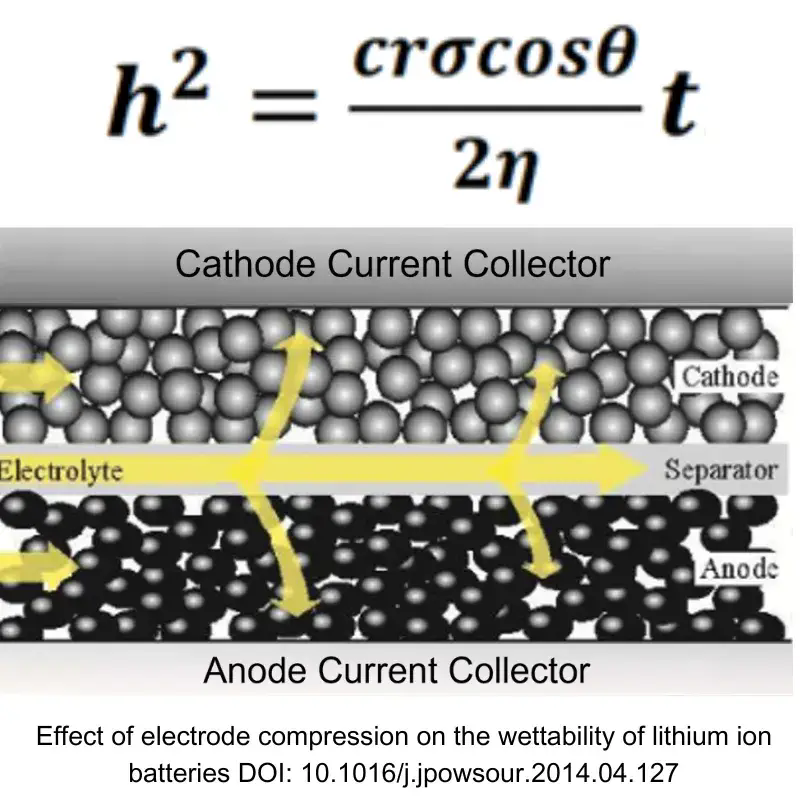

1. Principle of Electrode Wetting

The Lucas–Washburn Equation is commonly used to describe the dynamic of liquid absorption in electrode pores, as represented by the equation below:

1) r represents the radius of the capillary (m),

2) σ represents the surface tension of the imbibition fluid (N/m),

3) η represents the viscosity of the imbibition fluid (Pa*s),

4) θ represents the contact angle of the wet phase (°),

5) h represents the liquid suction height (m),

6) t represents the liquid suction time,

7) cr represents a fixed value, called the formal radius.

2. Applications

1) Electrolyte: Performance Evaluation

2) Electrode: Consistency Assessment

3) Optimization of material: Electrode Surface Treatment Processes

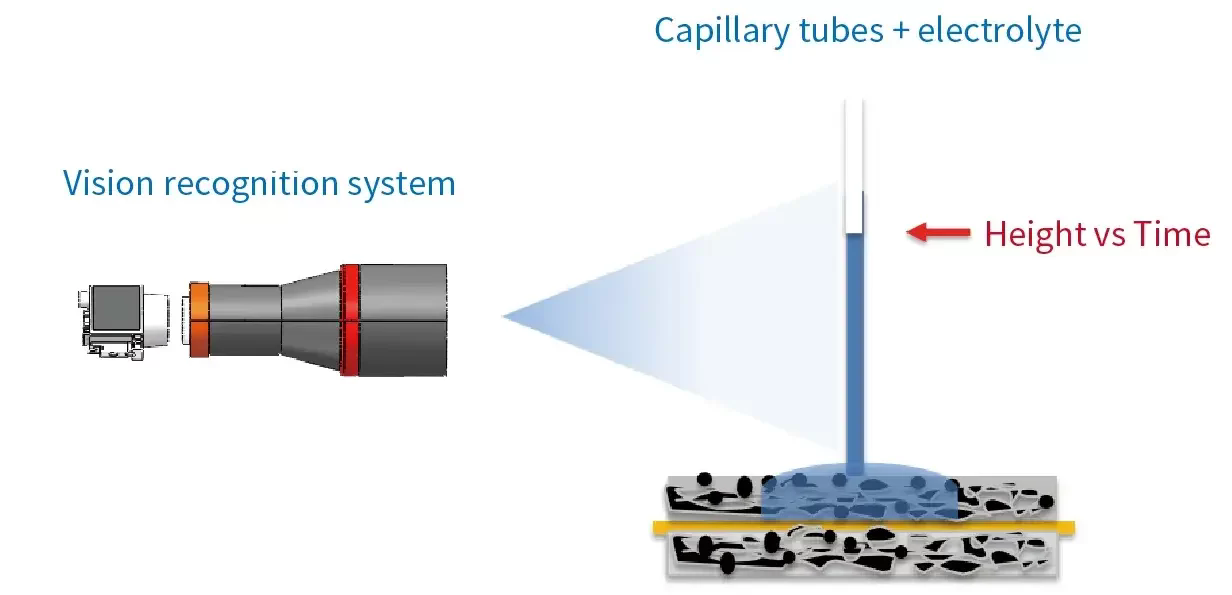

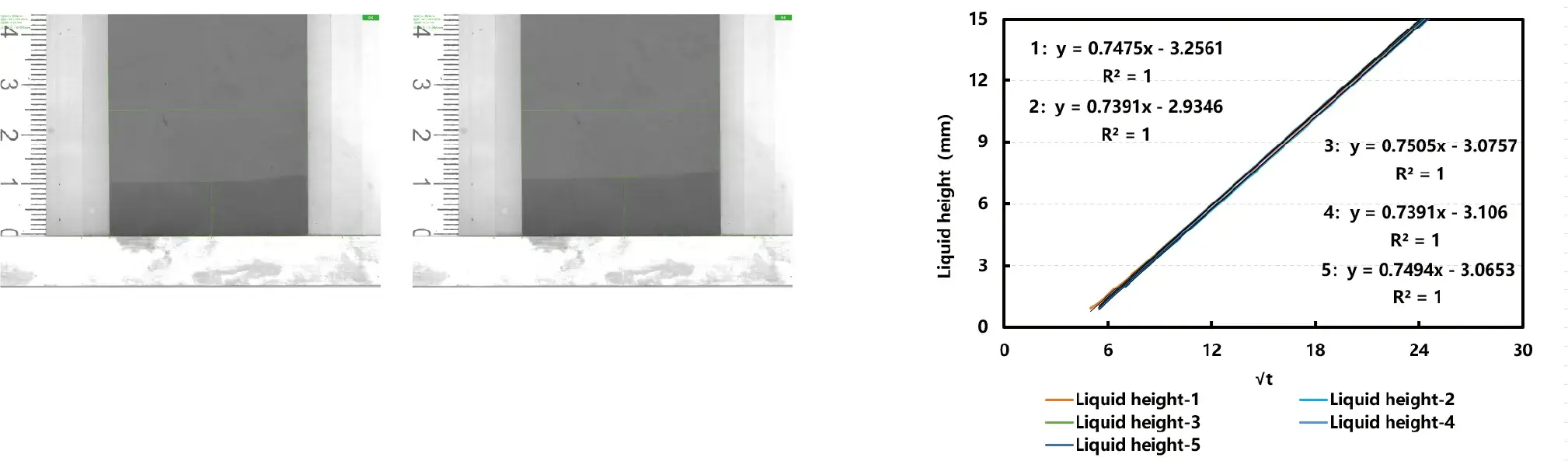

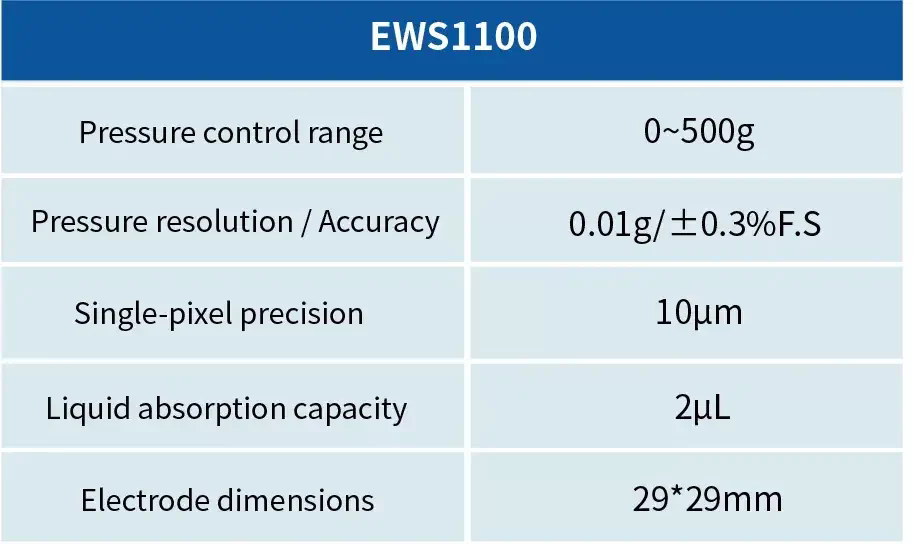

2.1 Capillary Wetting System-EWS Series

Key Features:

1) Equipped with a high-precision vision testing system for stable and efficient testing repeatability.

2) In-situ real-time characterization of electrolyte wetting rateon negative electrode sheets of lithium-ion batteries.

3) Applicable Samples: Negative electrode sheets.

4) The greater the compacticion of the electrode sheet, the lower the porosity, resulting in poorer electrolyte wetting.

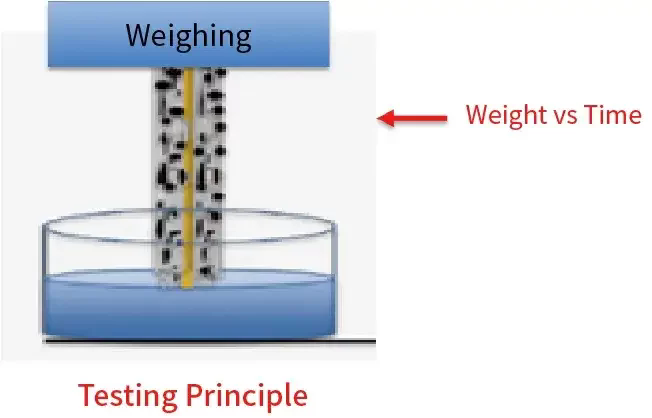

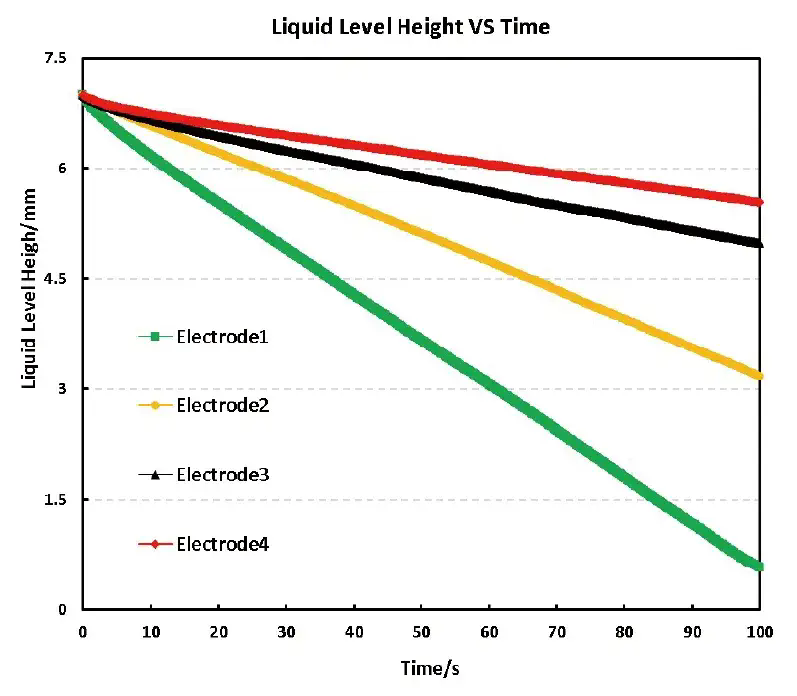

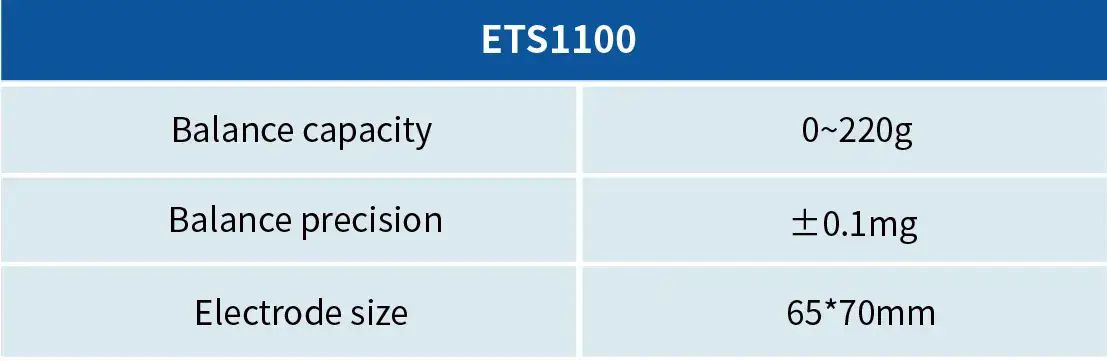

2.2 Weight Wetting System-ETS Series

Key Features:

1) Equipped with a high-precision weighing system for stable and efficient testing repeatability.

2) In-situ real-time characterization of electrolyte wetting rate on positive and negative electrode sheets of lithium-ion batteries.

3) Applicable samples: Anode electrodes & Jelly Cells

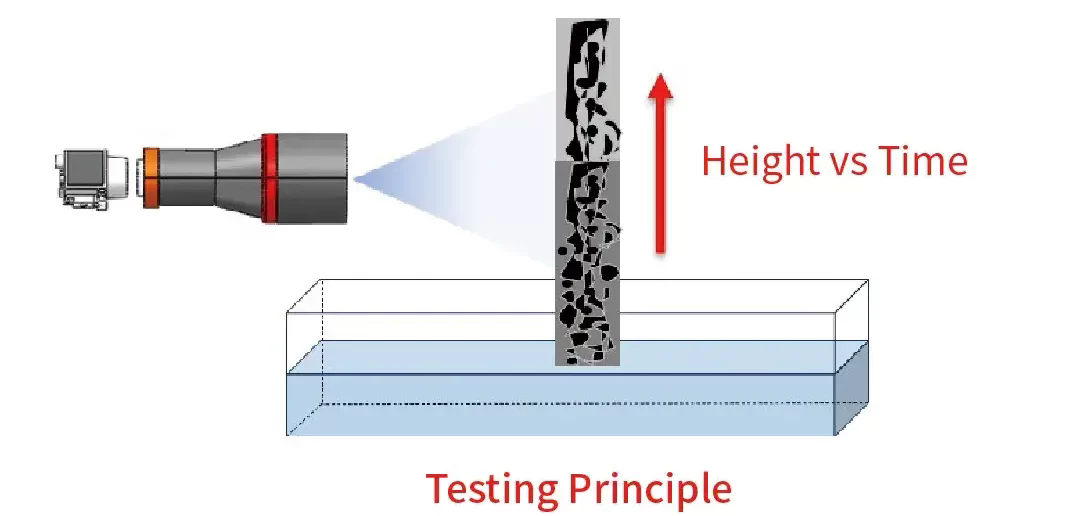

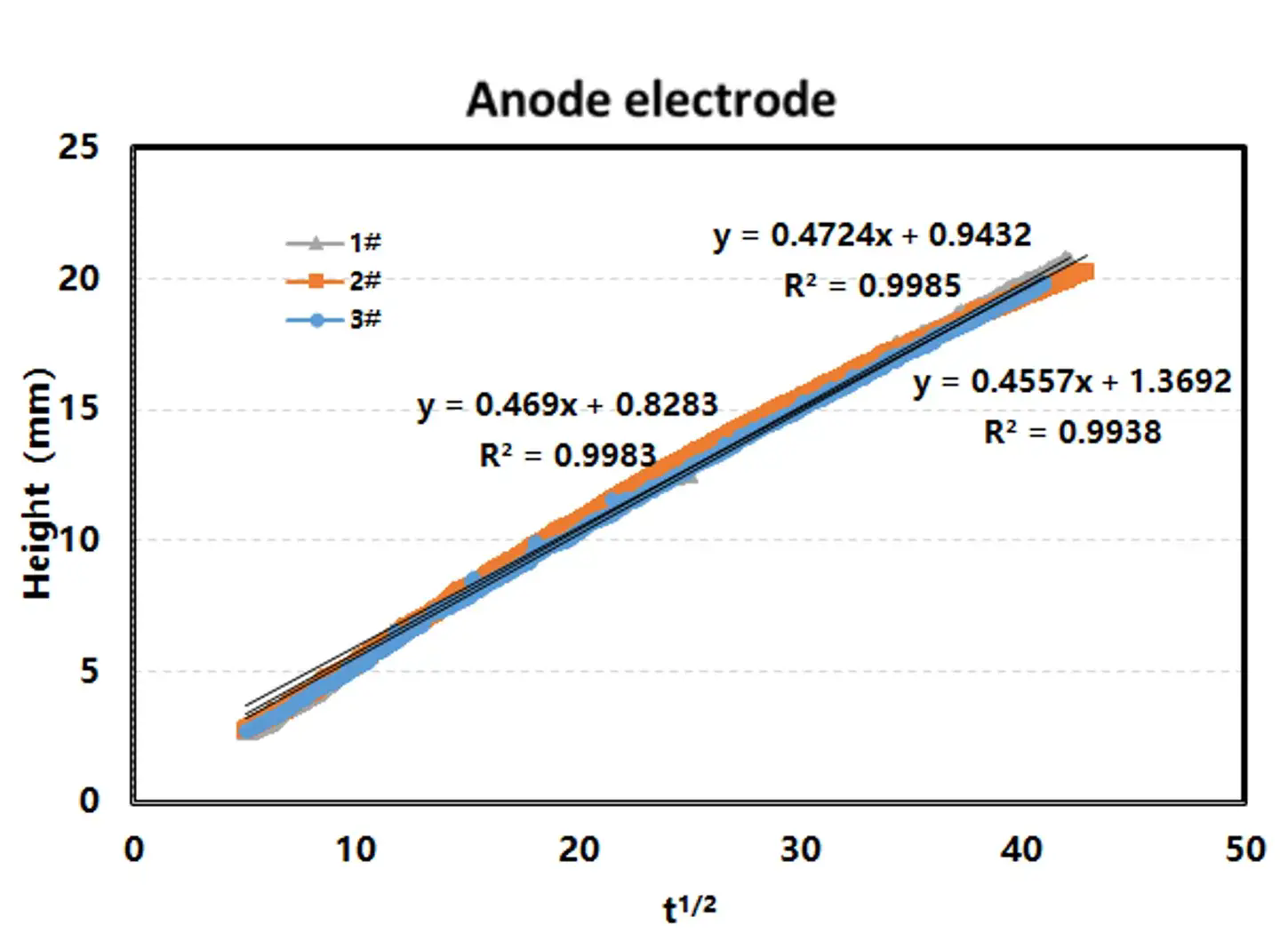

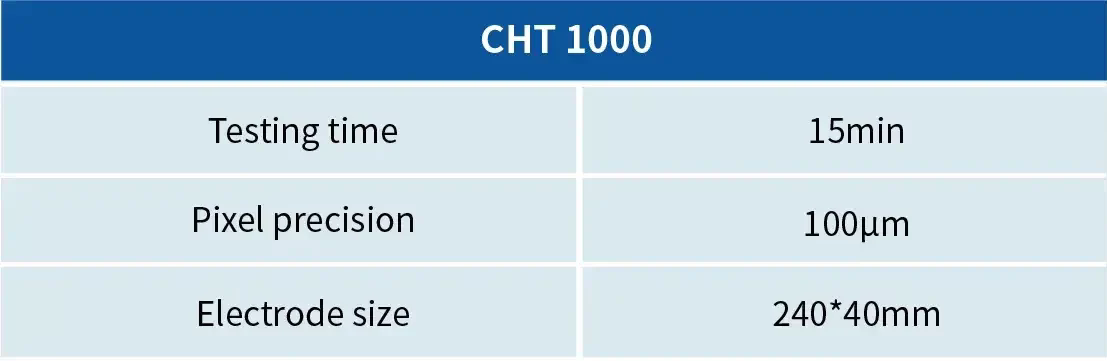

2.3. Height Wetting System-CHT Series

Key Features:

1) Equipped with a high-precision vision acquisition system for stable and efficient testing repeatability.

2) In-situ real-time characterization of electrolyte wetting rate on positive and negative electrode sheets of lithium-ion batteries.

3) Applicable samples: Anode electrodes

Application Cases

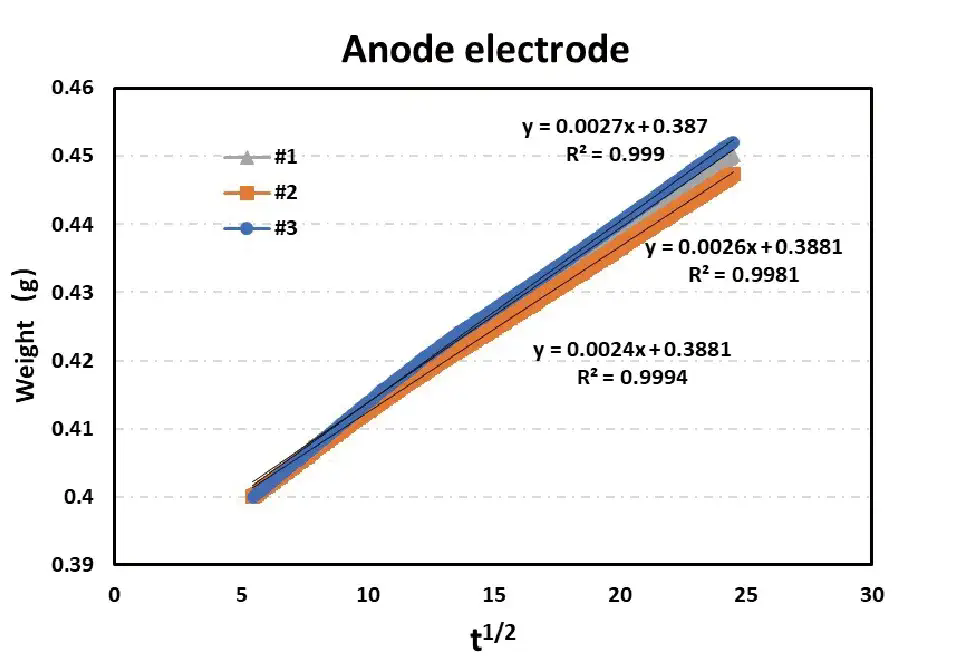

1. Capillary Wetting System-EWS Series

The greater the density of the electrode, the lower the porosity and the worse the electrolyte wettability.

2. Weight Wetting System-ETS Series

Trimming three sets of negative electrode sheets from the same batch (65*70mm)

3. Height Wetting System-CHT Series

The slopes of the 3 tested electrodes are consistent with each other, so is the wetting consistency of their electrolytes.

Specifications

Capillary Wetting System-EWS Series

Weight Wetting System-ETS Series

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com