products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Fiber Laser Cleaner Cleaning Machine 50W 100W Rust Removal Laser System

Model Number:

TMAX-OV-Q50Compliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Fiber Laser Cleaner Cleaning Machine 50W 100W Rust Removal Laser System

Laser Cleaning Advantages

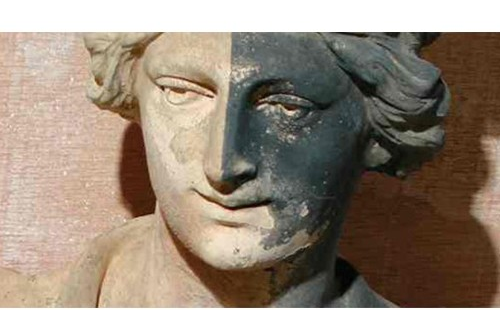

1) Laser cleaning has no grinding, non-contact, no thermal effect and suitable for various materials, etc.

2) Rapid, clean and accurate cleaning, removal of surface coatings, coatings, oxide;

3) No damage to substrate;

4) High cleaning precision, strong controllability;

5) Can be used for a long time, low operating costs;

6) The device can realize automatic operation and simple operation;

7) Environmentally friendly, no supplies, no two pollution.

Specification

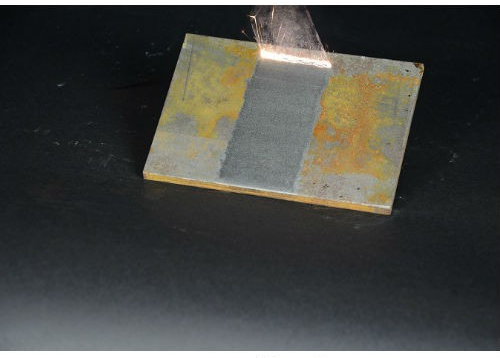

Laser Cleaning Rust Removal Machine is able to clean rust,oil stain,grease,dirt, resin,mold release,oil paint, coating,weld residue,oxide,production residue etc.

Laser Cleaning Tyre Mould

1.No medium,save cost for dry ice & sand-blasting abrasive.

2.No damanage to mould,prolong mould's service life.

3.No secondary ollutants.

4.Flexibly clean moulds with complicated and geometric construction surfaces.

High Precise Laser Cleaning Metal Components

1. No medium used, only electricity

2. Base material is not damaged

3. Higher levels of 'clean' can be reached

4. Easy to integrate in a production line.

Laser Descaling Metal Work-piece

1.No noise, no dust.

2.Stable process

3.Low running costs

4.Fast speed and effiecient derusting metal

Laser Removal Paintcoat

1. No medium,no dust and no chemicals.

2. Can remove coating,oxide,grease and other pollutants.

3. Compact design,move to any place easily.

Laser Cleaning in Pretreatment before Welding

1.Precise consistent cleaning results.

2. Safely cleans without abrasion .

3. Extends the service life of molds.

4. Molds can be cleaned hot or cold and in-line.

Laser Cleaning Oil Stain / Grease

1. Fast speed ,residue-free

2. No additional process steps necessary

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588