products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

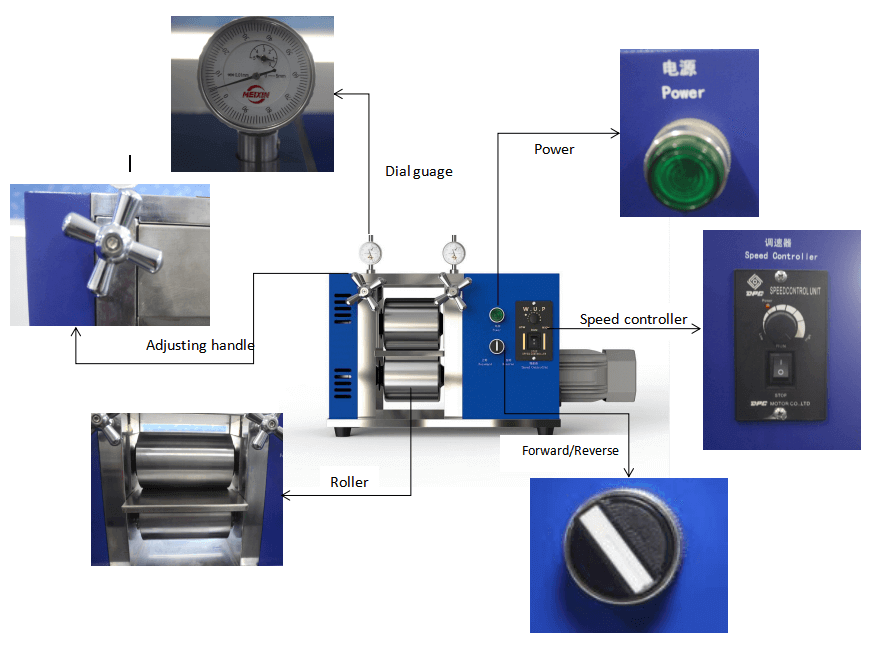

Heat Pressing/Roller/Calender Machine For rolling electrode(100-300mm width)

Model Number:

TMAX-DGNet Weight:

70-100kgCompliance:

CE CertifiedWarranty:

One-Year limited warranty with lifetime supportDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Lab Electrode Coater with Vacuum Chuck & 100-250mm Doctor BladeNext:

8" Width Heat Calendering Machine with Variable Speed up to 150C for Coin Cell Research

Electric Vertical Rolling Press Machine

Model Number: TMAX-DG200W

Application

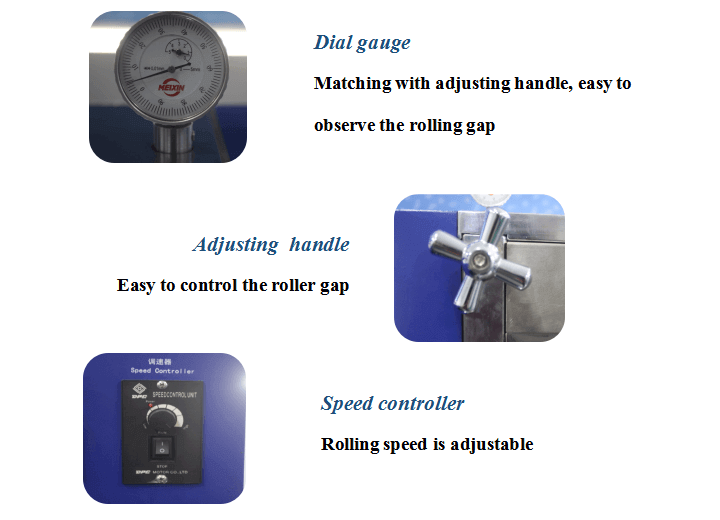

The Electric Vertical Rolling Press Machine is designed for laboratory-scale rolling of battery materials, small quantities of precious metals (gold, silver), and non-ferrous metals (copper, aluminum). It is particularly suitable for thinning and increasing the density of lithium battery electrodes used in clean energy applications. The machine utilizes a gear-driven system to achieve precise rolling pressure, with an adjustable rolling thickness for flexible operation.

Key Features

· High-hardness rollers, surface chrome-plated for rust prevention, achieving HRC62 hardness.

· Inclined wedge gap adjustment system, ensuring self-locking stability and high adjustment precision.

· High rolling accuracy, with roller cylindricity ≤ ±2μm.

· Vertical design, facilitating easy feeding of sheet and strip materials.

· Gear-driven system, enabling precise roller compression.

· Adjustable pressing thickness and speed, with a sleek and compact design.

· Electric rolling system, supporting automated operation with forward and reverse rolling.

· Compact size, ensuring ease of use and operational flexibility.

Technical Specifications

Parameter |

Specification |

Rolling Thickness |

0-2mm (Adjustable) |

Pressing Width |

0-200mm(customizable) |

Roller Diameter |

Φ96mm |

Roller Surface Hardness |

HRC62 or above |

Roller Surface Finish |

0.4 or above |

Roller Placement |

Vertical |

Power Supply |

AC220V / 50Hz(customizable) |

Power Consumption |

120W |

Feeding Speed |

0-50mm/s (Adjustable) |

Machine Dimensions |

L485mm × W245mm × H355mm |

Machine Weight |

65kg |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com