products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

High Efficiency 9 Channel Automatic 18650 26650 21700 32700 32650 Cylindrical Battery Sorting Machine

Model Number:

TMAX-FN-9Dimension(L*W*H):

1260x650x1350mmNet Weight:

120 kgCompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Lithium Battery Cell Insulating Adhesive Paper Insulator Pasting Machine with Optional Channel Cylindrical Battery SorterNext:

6 Channels 18650/26650/32650 Li-ion Battery Cells Testing &Sorting Machine

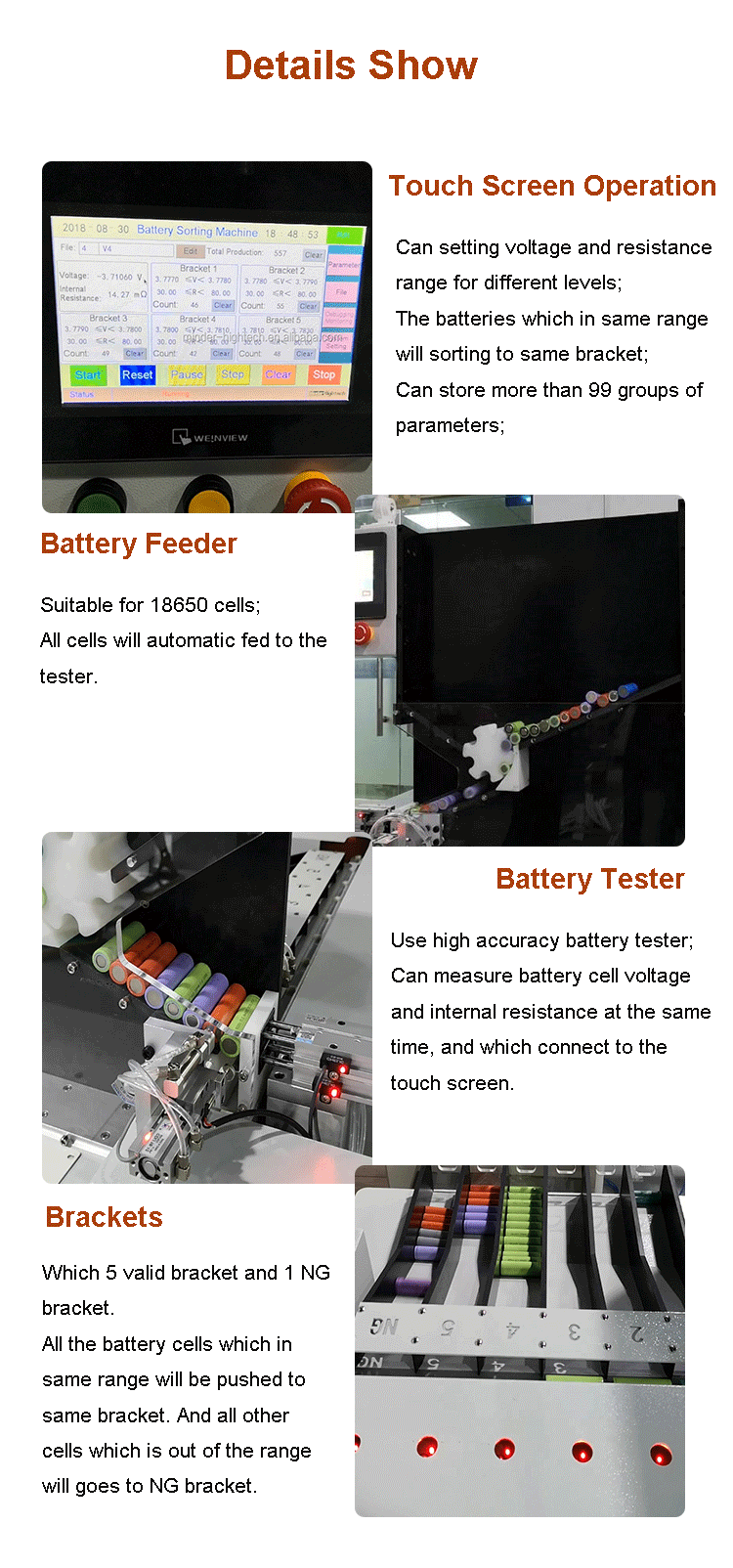

High Efficiency 9 Channel Automatic 18650 26650 21700 32700 32650 Cylindrical Battery Sorting Machine

Features

1. Compact and reasonable equipment structure, beautiful appearance, small volume.

2. Simple equipment operation, workers can easily learning.

3. The equipment is controlled by PLC and PC. The PLC is responsible for battery feeding, battery handling and battery sorting. The PC is responsible for battery testing data collection, voltage internal resistance rating, high work efficiency, saving manpower, good product performance.

4. Equipment materials are made of high quality thick cold-rolled sheet metal, aluminum frame.

5. The device is equipped with universal movable casters, the device can easily move when it is displaced.

Specifications

Model |

TMAX-FN-9 |

Power supply |

AC220V ± 10% 50Hz |

Voltage |

800W |

Sorting parameters |

Open Circuit Voltage and AC Internal Resistance |

Compressed Air Pressure |

0.5 ~ 1.0Mpa |

Sorting Speed |

≥80PPM |

Productivity |

5000pcs/h |

Dimension |

1260x650x1350mm |

Adaptation Battery

|

Cylindrical Battery (18650,32650,18500,26650,14500,21700 etc.) |

Receiving Channel |

9 channels |

Internal Resistance Tester |

HIOKI3561 or HK3561

|

|

HIOKI3561: Open circuit voltage accuracy:± 0.01% rdg; Internal impedance accuracy:± 0.1% rdg; HK3560: Open circuit voltage accuracy: ±0.1% RDG Internal impedance accuracy:±0.5% RDG |

Total weight |

120kg |

Control component |

7.5 inch touch screen, 3-axis PLC programmer |

Motion device

|

Closed-loop stepper motor is used for shifting, accurate positioning and synchronous belt conveying the core to prevent the surface of the core from being damaged. |

Feeding |

Using hopper feeding mode, 500 PCS can be put in one time. |

Data storage |

Test data can be stored on a U disk |

Scan code function |

Can be customized |

Automatic Online Interface

|

It can be customized to connect the outlet of the automatic surface cushion machine in the machine hopper to realize the automatic connection of the electric cores and save the labor cost. |

Other |

Customizable scanner and database data docking |

|

Optional Distribution Core Dynamic Tester, reflecting the quality and load-carrying performance of the core |

|

Customizable automatic connection automatic surface mattress machine (electric core poured into automatic surface mattress machine, pasted surface mattress automatically flowed into automatic sorter, sorting, saving manpower) |

|

Automatic collection of production quantity to show current production efficiency |

Equipment Configuration List

Tester |

HIOKI3561 or HK3561 |

Computer |

Industrial Computer |

PLC |

FX3U-80MT/ES-A and SC-09 |

Servo |

Panasonic A5 Series |

Sensors |

Panasonic and Omron, Japan |

Guideway |

ShangYin, Taiwan |

Bearing |

Japan NSK |

Cylinder |

Adec |

Indoor temperature |

- 30 ℃ ~ 70 ℃ |

Factory |

No pollution and no strong electromagnetic interference |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com