products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

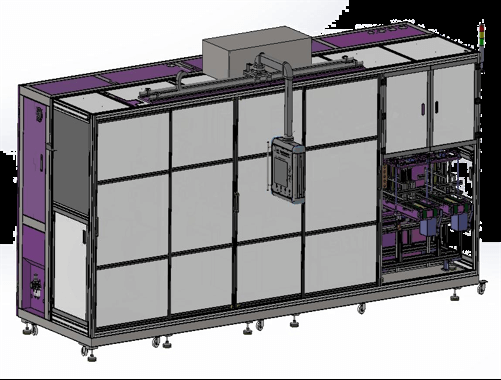

High-Speed Die-Cutting Machine With Gap Coating

Model Number:

TMAX-ZTH-02Compliance:

CE CertifiedWarranty:

Two years limited warranty with lifetime supportDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Dual-Station High-Speed Battery Stacking Machine for Lithium BatteryNext:

Three Layer Double Door Intelligent High Vacuum Oven

High-Speed Die-Cutting Machine With Gap Coating

Features

Specification

Project |

Parameter |

Production efficiency |

>180PPM |

Burr size |

Vas12um ; Vbs12um |

Deviation correction accuracy |

≤±0.1mm |

Slice forming accuracy |

±0.2mm |

Mold Life |

1. After each mold repair, it can be used no less than 1.5 million times; 2. The number of times the mold can be repaired ≥ 10 times; |

Material box receiving accuracy |

±0.5mm |

Qualification rate |

≥ 99.8% (defects caused solely by the machine) |

Crop growth rate |

≥ 98% (faults caused solely by the machine) |

Overall dimensions |

W1750mm x L7000mm x H2350mm |

Weight/bearing capacity |

About 3000kg; >650Kg/M-2 |

Power |

AC380V three-phase; Voltage fluctuation ± 10%; Power: 30KW; Frequency: 50Hz |

Compressed air |

0.5-0.7Mpa (5-7kgf/cm2), dosage 400L/min |

Project |

Parameter |

|

Punching method |

Metal mold punching |

|

Material system |

Continuous coating of electrode sheet coil material after slitting, with one side outlet lug |

|

Roll diameter |

≤ 600mm |

|

Inner diameter of drum |

3"/6" |

|

Pole winding error |

士3mm |

|

Snake shaped bending error of polar plate |

±1mm/m |

|

Height difference of polar wave edge |

<2mm |

|

Pole width W |

60~200mm |

|

Pole length L |

80~300mm |

|

Pole ear length H |

10~30mm |

|

Pole ear edge distance Q |

5-20mm |

|

Pole ear width P |

10~50mm |

|

Pole ear belt material X |

0~2mm |

|

Round RB |

2~5mm |

|

Round corners RA |

Inner rounded corner |

Outer rounded corner |

Production Assembly Plant

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com