products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

In-Situ Multi-Channel Battery Storage Gassing System

Model Number:

TMAX-MSG2000Compliance:

CE CertifiedWarranty:

1 Year limited warranty with lifetime supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

In-Situ Battery Gassing Volume AnalyzerNext:

Electrochemical Workstation With EIS Test Potentiostat/Galvanostat Battery Cycler ERT Series

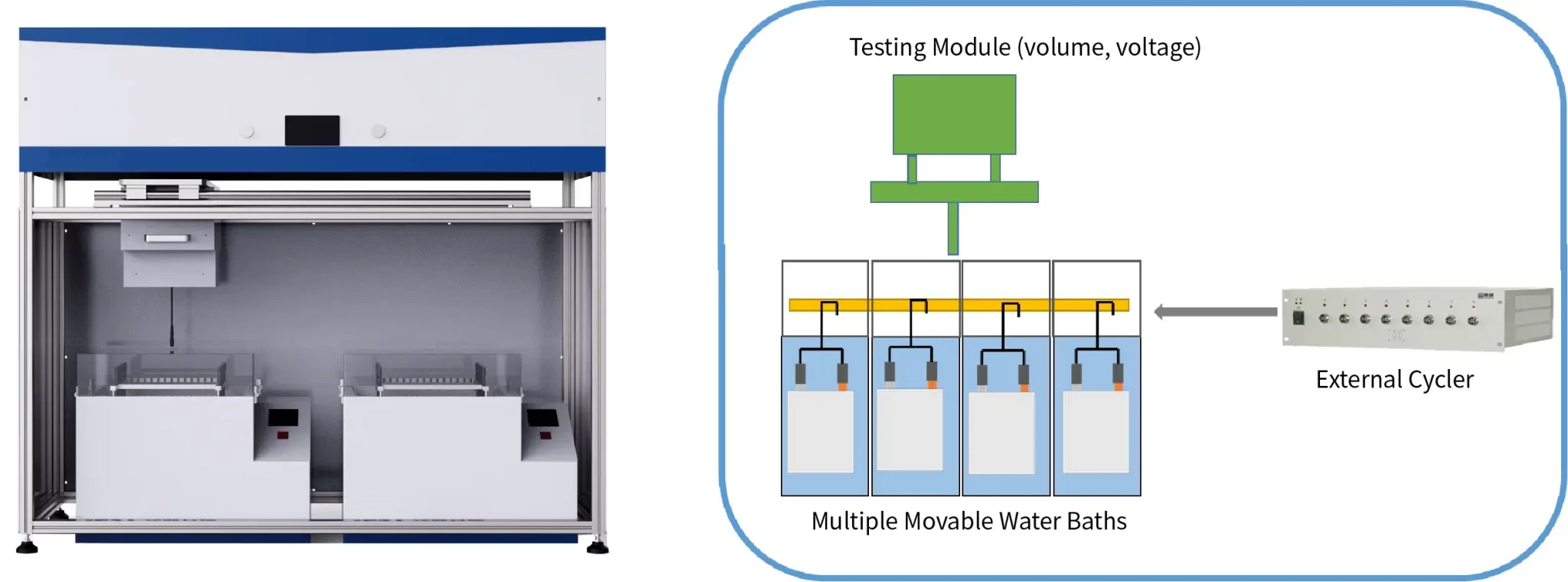

In-Situ Multi-Channel Battery Storage Gassing System

Characteristic

1. In-situ Storage Gassing testing for pouch cells

2. Multi-channel Testing (up to 64 channels)

3. Automatical Data Recording(volume, voltage and internal resistance)

4. Access to External Cyclers

Description

1. Disadvantages

1) The temperature changes duringthe process result in gas generation and testing losses.

2) Manual data recording may introduce errors, as data collection must be done manually.

| Traditional – Oven & Balance Method | TMAX In-Situ Storage Method | |

Equipment Setup |

Requires multiple devices: oven, voltmeter, balance, charging/discharging equipment | Integrated equipment |

Equipment Functions |

Temperature change, volume, voltage |

Temperature change, volume, voltage, supplementary power |

Volume Measurement Precision |

Low precision, > 50μL |

High precision, < 30μL |

Operation Mode |

Complicated, requires transferring cells multiple times |

Simple, in-situ measurement, no transfer needed |

| Data Recording | Manual multiple recordings | Software automatic recording |

2. Features

2) Multi-channel Testing (up to 64 channels)

3) Automatical Data Recording(volume, voltage and internal resistance)

4) Access to External Cyclers

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com