products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

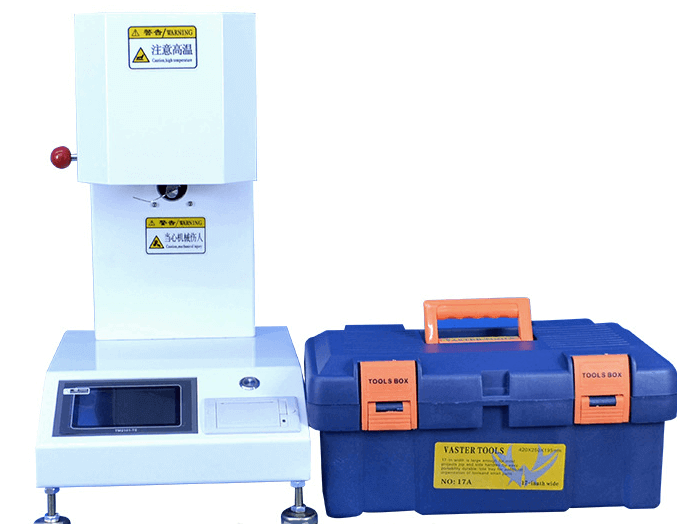

Lab Melt Flow Indexers with Printer and Complete Weights

Model Number:

TMAX-QL400Compliance:

CE CertifiedWarranty:

1 yearMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Heat Shrinkable Pipe Silicone Tube Rubber Pipe PVC Hose Automatic Cutting MachineNext:

Laboratory Thermal Cycler PCR Machine for DNA Copy

Lab Melt Flow Indexers with Printer and Complete Weights

The Melt Flow Index (MFI) is a bench-top structure, with a reasonable design, stable and reliable performance, beautiful appearance, and convenient operation.It uses high-performance and high-precision control instruments with high sampling accuracy and fast control rate. It uses fuzzy PID algorithm for constant temperature control.

The melt flow indexers is applicable to the determination of the specified mass melt flow rate of thermoplastics in the national standard of "GB / T3682-2000 Thermoplastic Melt Mass Flow Rate and Melt Volume Flow Rate". This standard also uses the same The requirements of ISO 1133: 1997 can also meet the ASTM D1238 test standard.

Features

1. Fast heating speed with minimal overshoot

2.High constant temperature accuracy

3. After filling, it can quickly return to a constant temperature.

4.Easily calibrate and modify test parameters

5.Can use manual and automatic cutting test method

6. English LCD display

7. Equipped with a printer to print the test results automatically

Usage

It is used to measure the melt flow rate MFR value of various plastics and resins in the viscous state. It is suitable for engineering plastics such as polycarbonate, polysulfone, fluoroplastics, nylon, etc., which have high melting temperatures, and polyethylene. (PE), polystyrene (PS), polypropylene (PP), ABS resin, polyoxymethylene (POM), polycarbonate (PC) resins and other plastics with lower melting temperature testing, widely used in plastic production, plastic Products, petrochemical industry, and related colleges, scientific research units and commodity inspection departments.

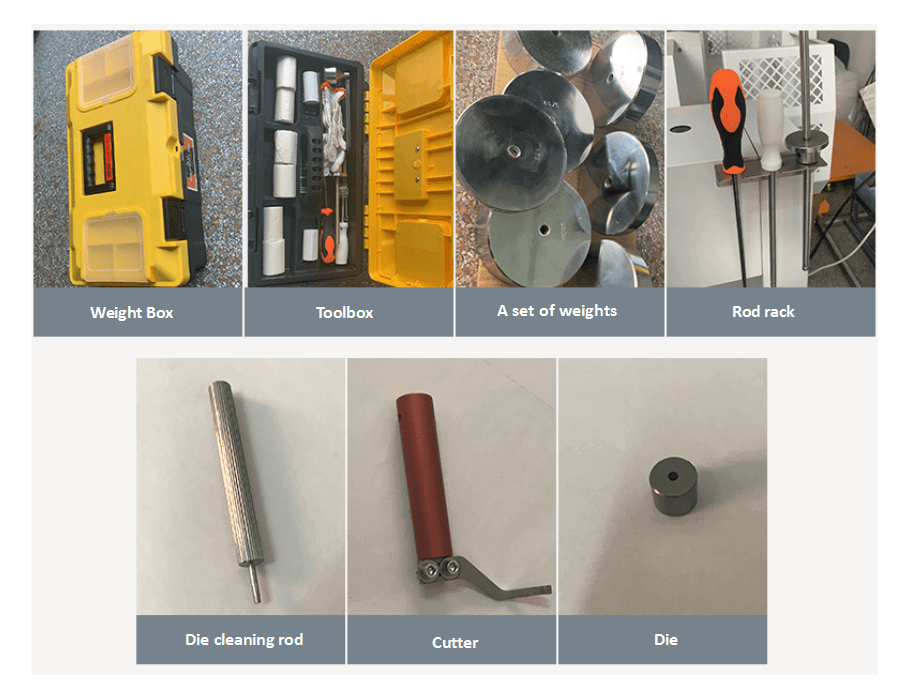

SPECIFICATIONS

Power supply |

AC220V±10%, 50Hz |

Extruded part |

Discharge opening diameter: Φ2.095 ± 0.005 mm, discharge opening length: 8.000 ± 0.025 mm Loading cylinder diameter: Φ9.550 ± 0.025 mm, charging cylinder length: 152 ± 0.100 mm Piston rod head diameter: 9.475 ± 0.015 mm, piston rod head length: 6.350 ± 0.100 mm |

Standard test load |

8 degree weights are included |

Temperature range |

RT- 450℃

|

Constant temperature accuracy |

±0.2℃ |

| Display resolution | 0.1 ℃ |

Cutting mode |

manual or automatic cutting |

Temperature recovery time |

less than 4 minutes |

Printing |

micro printer automatic printout |

| Optional part | Volumetric test method |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com