products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

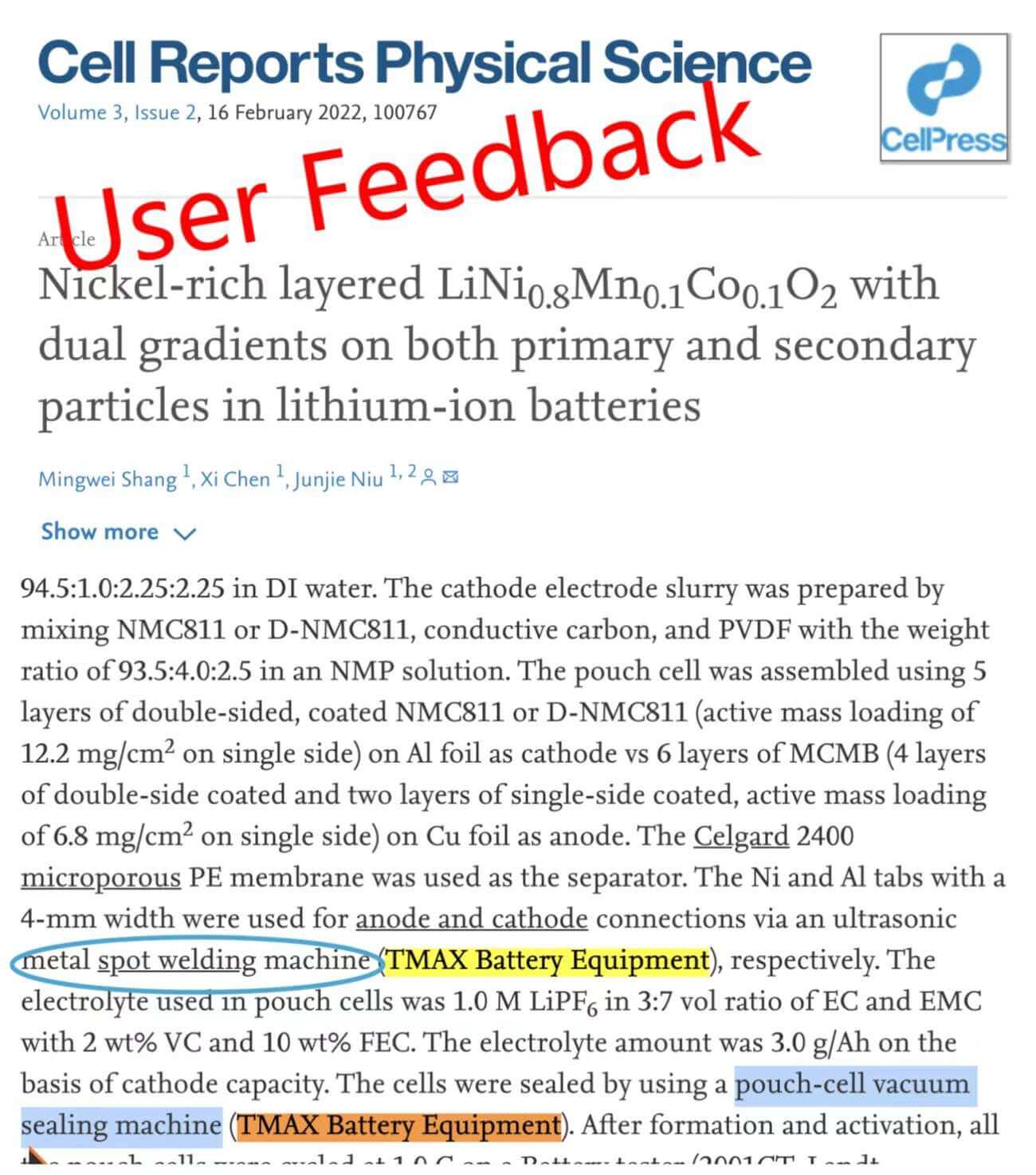

Lab Pouch Cell Vacuum Sealing Machine for Battery Pre-Sealing in Glove Box

Model Number:

TMAX-YFCompliance:

CE CertifiedWarranty:

2 Year Limited Warranty With Lifetime SupportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Pouch Cell Tab Ultrasonic Metal Spot Welder Welding MachineNext:

Laboratory Compact Lab Planetary Ball Mill (50-5000 mL Jars) for Li-ion Battery

Lab Pouch Cell Vacuum Sealing Machine for Battery Pre-Sealing in Glove Box

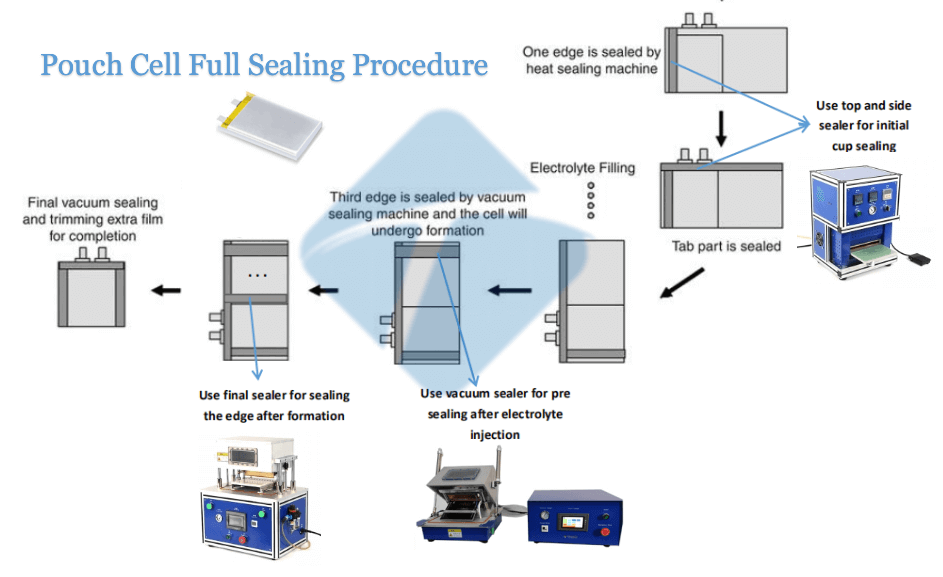

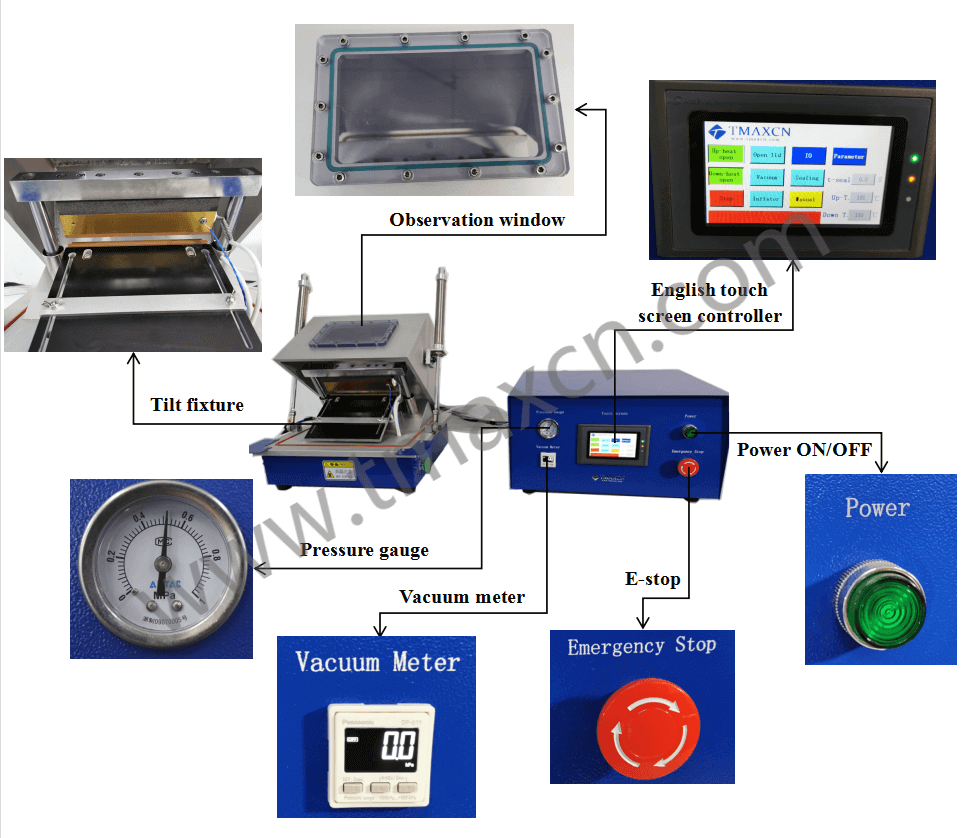

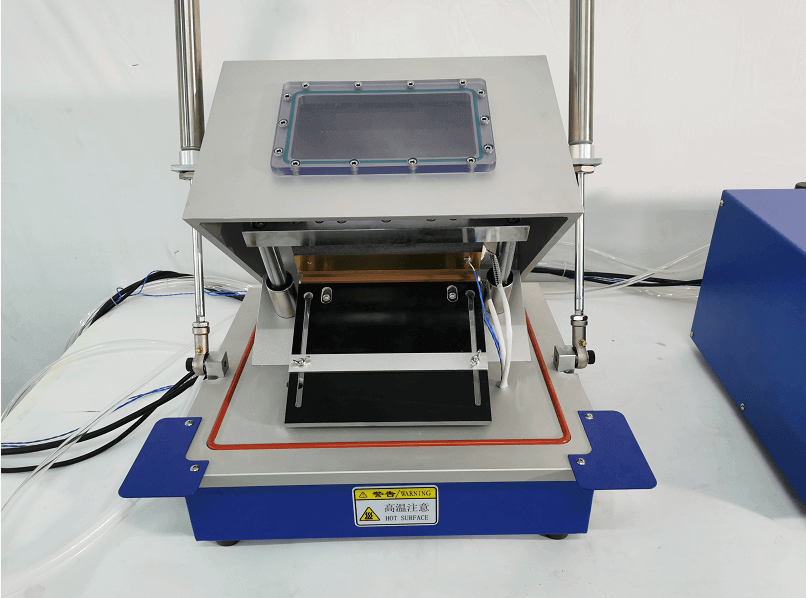

This equipment is mainly suitable for vacuum hot sealing of pouch cell after electrolyte filling and standing; the machine can automatically complete vacuum thermal sealing of aluminum laminated film by precisely controlling the main vacuum pumping box and pneumatic heat sealing components.

*Simple operation, beautiful appearance, small volume and light weight.

More info about vacuum sealer you can visit our site directly.

Specification

Chamber |

The chamber is made of aluminum alloy, which is corrosion resistant and has a firm structure; |

Vacuum degree |

The vacuum degree can be adjusted up to -95Kpa (the buyer shall provide the vacuum pump); |

Head temperature |

Room temperature~250℃, temperature adjustable; |

Temperature control accuracy |

±2℃; |

Heat sealing pressure |

0~7Kg/cm2 adjustable; |

Heat sealing time |

0~99 seconds adjustable; |

Edge sealing width |

5±0.4mm (can be customized) |

Maximum edge sealing length |

200mm (can be customized, such as 300/400/500mm sealing length) |

Seal thickness range |

60~300um |

Seal thickness accuracy (mm) |

Sealing thickness difference between any two points<15um |

Air consumption |

About 0.2L compressed gas per seal once. |

Working speed of air compressor |

≥180 times/h |

power |

Using 300w heating tube, the power consumption when heating is about 0.6KW. |

Power Supply |

220V/50Hz; |

Compressed air source |

0.5~0.8Mpa; When used in the glove box, the cylinder power source must use the same working gas used in the glove box; |

Working chamber |

470mm*485mm*435mm; |

Control box |

420mm*325mm*225mm |

Equipment weight |

About 50Kg |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com