products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Sodium Ion Battery Production Line

- Solid State Battery Assembly Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Battery Material Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- Hydraulic Press

- Ball Mill

- Planetary Centrifugal Mixer

- Laboratory Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Laboratory Battery 8000M3/H NMP Solvent Recovery System For Prismatic Cell Production

Model Number:

TMAX-8000SL-1Compliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 13003860308

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Laboratory Battery 8000M3/H NMP Solvent Recovery System For Prismatic Cell Production

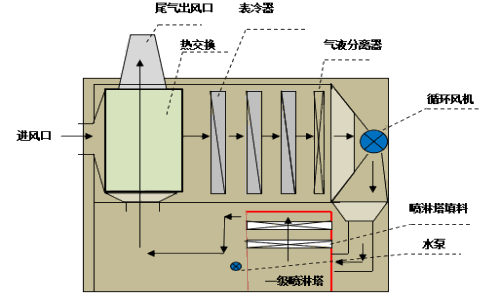

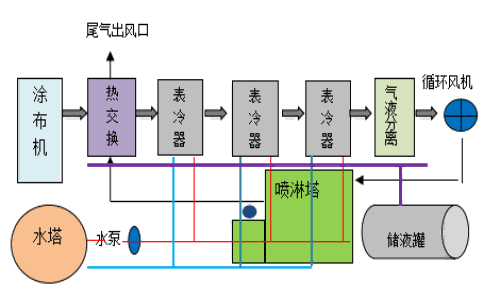

Principle introduction

It is used for the recovery of N-Methyl-2-pyrrolidone (NMP) organic solvent in the waste gas discharged from the coating machine during the production of lithium ion batteries. Under the condition of low energy consumption, the waste gas can be discharged up to the standard to achieve environmental protection, energy conservation and raw material recycling. The NMP exhaust gas of this system is discharged into the atmosphere after being cooled by cooling circulating water and treated with tail gas mist removal. After treatment, the concentration of tail gas emissions is much lower than the national emission standards, meeting environmental protection requirements.

Equipment Usage

It is mainly used in the lithium battery industry; A high-performance environmental protection equipment for the treatment of NMP waste gas generated during the coating process of lithium battery manufacturing.

Equipment characteristics

The combination of water-cooled spray is used to treat and purify NMP waste gas, which has efficient recovery function and purification effect.

The equipment is easy to operate and has clear instructions.

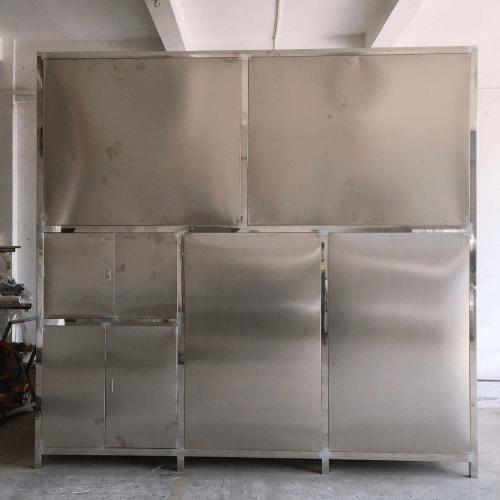

Combined design, main components can be easily disassembled and maintained.

Efficient recycling of NMP has high economic benefits for users.

Technical guidance

Exhaust gas evacuation organic matter concentration |

<50 mg/m3 |

NMP recovery rate |

99%±3% |

NMP recovery concentration |

≥80% |

Environmental requirements

A ambient temperature:+10~+40 ℃

B Environmental humidity: 20-90%

C Altitude:<1000 meters

D Applicable exhaust gas temperature:<120 ℃,

Flow chart

Equipment component parameters

No |

Mechnism Name |

Component Name |

Material quality |

Specification |

Manufacturer |

1 |

Host configuration |

Heat exchanger |

Aluminum tube |

800*800*350 |

Self-made |

2 |

Surface cooler |

Copper tube, aluminum wing |

800*800*200 |

ASD |

|

3 |

Surface cooler |

Copper tube, aluminum wing |

800*800*200 |

ASD |

|

4 |

Surface cooler |

Copper tube, aluminum wing |

800*800*200 |

ASD |

|

5 |

Gas-liquid separator |

304 stainless steel |

800*800*50 |

Self-made |

|

6 |

Induced draft fan |

Stainless steel |

3KW |

Aozhong/Xinfeng |

|

7 |

Host box |

201 stainless steel |

1.5mm |

Self mate |

|

8 |

Overall frame column |

201 stainless steel |

50*50*3 |

Hong'echeng/Dahua |

|

9 |

Machine outer frame sealing plate |

201 stainless steel |

1.0mm |

Hong'echeng/Dahua |

|

10 |

Spray tower |

Tower body |

201 stainless steel |

1200*1000*1700*1.5mm |

Hong'echeng/Dahua |

11 |

filler |

304 stainless steel |

800*800 |

Self-made |

|

12 |

injector |

316 stainless steel |

DN10 |

Self-made |

|

13 |

Circulating water pump |

Anticorrosive materials |

1.5KW |

Yuanli |

|

14 |

Cooling system |

water tower |

glass fibre |

30T |

Liang Yuan |

15 |

|

Cooling fan |

cast iron |

1.5KW |

Liang Yuan |

16 |

Circulating water pump |

Anticorrosive materials |

2.2KW |

Yuanli |

|

17 |

Liquid storage device |

Lower liquid tube |

Aluminum plastic |

2.0 |

Zeko |

18 |

|

Liquid storage tank |

201 stainless steel |

1.5T |

Self-made |

Control system configuration parameters

No |

Name |

Specification |

Qty |

Manufacturer |

1 |

Air switch |

4P/32A |

1pcs |

chint |

2 |

Unipolar switch |

1P/10A |

2pcs |

chint |

3 |

AC contactor |

1210 |

3pcs |

chint |

4 |

Thermal overload relay |

4A/6A |

3pcs |

chint |

5 |

Indicator light |

Red, green |

2pcs |

chint |

6 |

Transfer switch |

NP2 |

2pcs |

chint |

7 |

Fuses |

6A |

1set |

chint |

8 |

Temperature controller |

18/H |

2pcs |

chint |

9 |

Warning light |

Ad16-22sm |

1pcs |

chint |

10 |

Control electrical box |

400*500*200、400*400*1500 |

1pcs each size |

chint |

Equipment power configuration

Device Name |

Power |

Circulating fan |

3kw |

Circulating water pump |

2.2 kw |

cooling tower |

1.5 kw |

Spray pump |

1.5kw |

Pumping pump |

0.55 kw |

NMP recovery device power |

8.75kw |

Picture for reference

Cindy@tmaxcn.com

Cindy@tmaxcn.com David@tmaxcn.com

David@tmaxcn.com +86 13003860308

+86 13003860308 18659217588

18659217588