products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Laboratory Battery Internal Short Circuit Testing Machine for Lithium Battery R&D

Model Number:

TMAX-YK-Y0263Compliance:

CE CertifiedWarranty:

One year limited with lifetime supportMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Laboratory Battery Drop Tester Testing Machine for Lithium-ion Battery R&DNext:

-70℃~150℃ High Low Temperature Testing Chamber Temperature Humidity Test Equipment

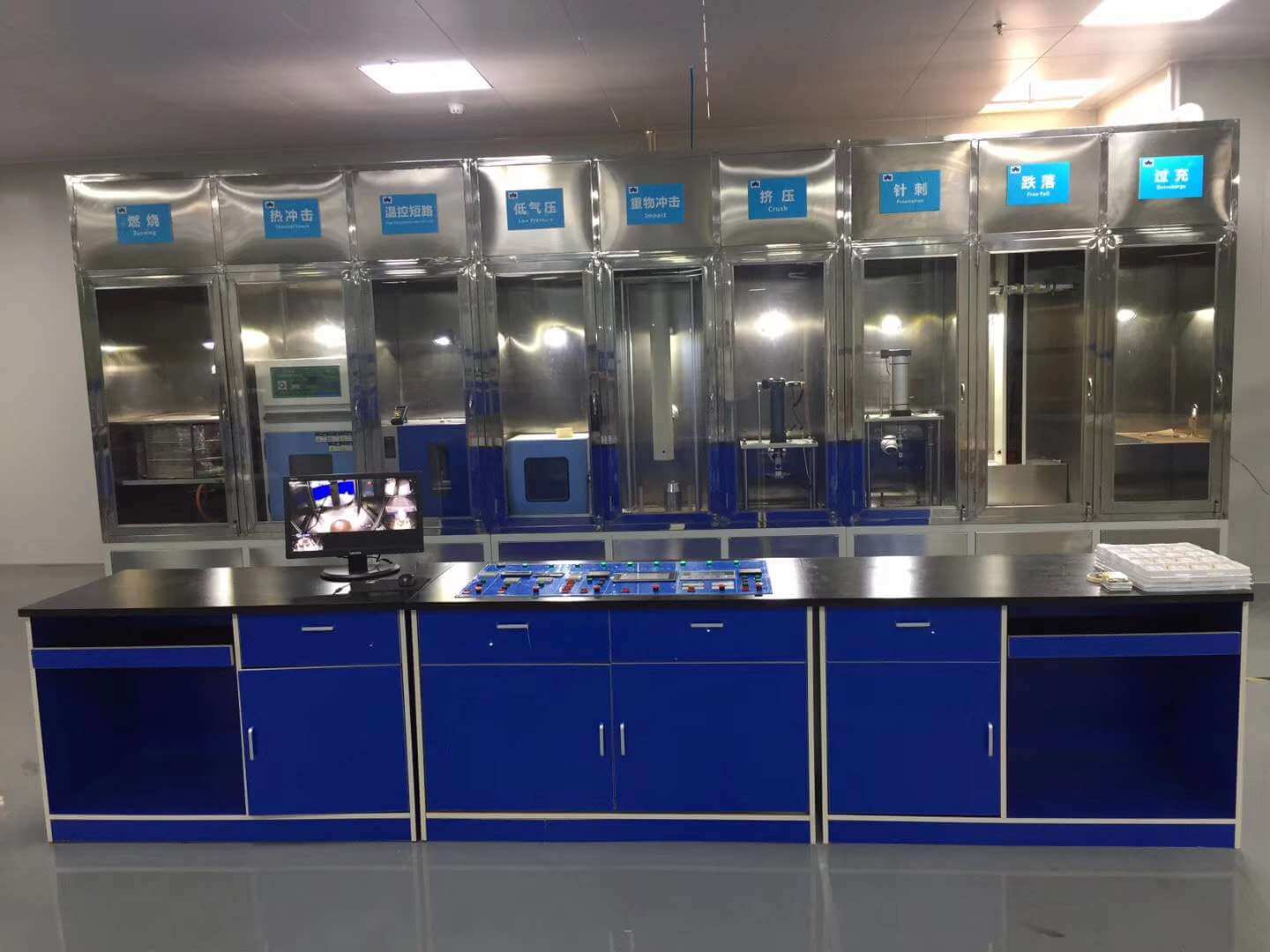

Laboratory Battery Internal Short Circuit Testing Machine

for Lithium Battery R&D

Introduction

This product is designed in accordance with the latest battery test standards such as Japanese Industrial Standards JISC 8714:2007, IEC62133-2013, and simulates the forced internal short circuit test of the battery under certain ambient temperature conditions. The test box is made of stainless steel, with good temperature uniformity and exhaust function (That is, test exhaust gas is discharged after the test is completed). The control system is a PLC touch screen menu operation, and the data collection frequency can reach 100 times per second. At the same time, the test pressure, pressure holding time, measured pressure, battery voltage, battery temperature, pressure drop speed, etc. are set through PLC programming.

Technical parameter

Material of extrusion table |

High-grade stainless steel plate, corrosion-resistant |

Indenter size |

10*10*5mm or 10*10*2mm |

Capacity |

0-1000N |

Unit conversion |

kg, lb, N |

Test stroke |

0-100 mm (excluding fixtures) |

Accuracy of stroke |

±0.05 mm |

Test speed |

0.1mm/S, that is, 6 mm/min (adjustable within 0~20mm/min) |

Load resolution |

1/10,000 |

Load accuracy |

Less than ±0.5% |

Squeeze action |

apply pressure from top to bottom; |

Test procedure |

At a speed of 0.1mm/S, using standard pressurized tooling, apply pressure to the part where the small nickel sheet is placed on the single battery, and at the same time use the voltage acquisition system to monitor the voltage change at the battery output terminal (voltage acquisition frequency is 100 times/ Seconds) When a voltage drop greater than 50mV is observed, or when the applied pressure reaches the requirements (cylindrical battery 800N, prismatic battery 400N), stop reducing the pressurization tooling and keep it for 30s, and then remove the pressure; voltage monitoring data sampling Frequency: 100 times/second |

Transmission system |

Original imported servo stepping motor (Panasonic, Japan) |

Control system |

Adopts PLC touch screen controller, which can realize the control of pressure, battery voltage, battery temperature and other parameters |

The temperature range of the high and low temperature test chamber |

0 ~ 100℃ |

Temperature display accuracy |

±0.5℃, thermostat: TEMMI controller imported from Korea |

Temperature uniformity |

±2℃ |

The inner box size of the test box |

600*500*500mm Heating time: 3℃/min (average heating, non-linear no-load) |

Cooling time |

1℃/min (average cooling, non-linear no-load) |

Inner box material |

First-class mirror stainless steel plate |

Outer box material |

Stainless steel matte line treatment |

Insulation material |

Rigid polyurethane foam + high-efficiency compressed glass wool |

Heater |

Fin-type radiating tube-shaped stainless steel electric heater |

Air circulation system |

Convective air circulation system |

Protection device |

Non-fuse switch, over-temperature protection switch, fuse, front-opening tempered glass observation window, and explosion-proof lock |

Safety device |

The first over-temperature alarm, MCCB overload protection, etc. |

Electricity source |

1∮, 220V/50HZ |

Machine weight |

about 220kg |

If you customize more than six machines, you can integrate the machines into a comprehensive console

![]()

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com