products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

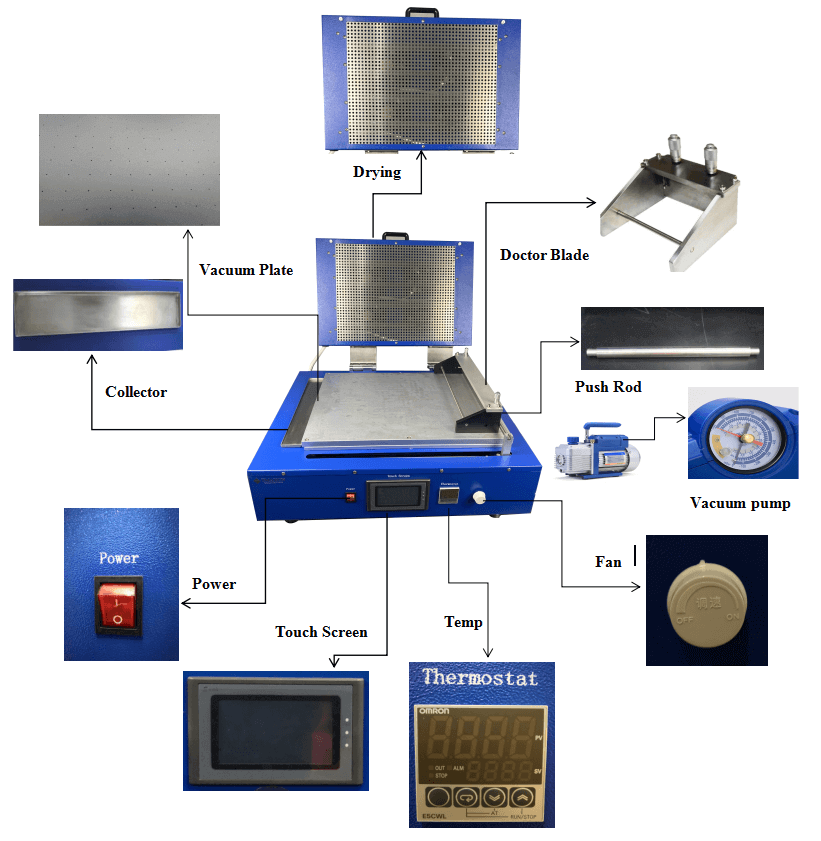

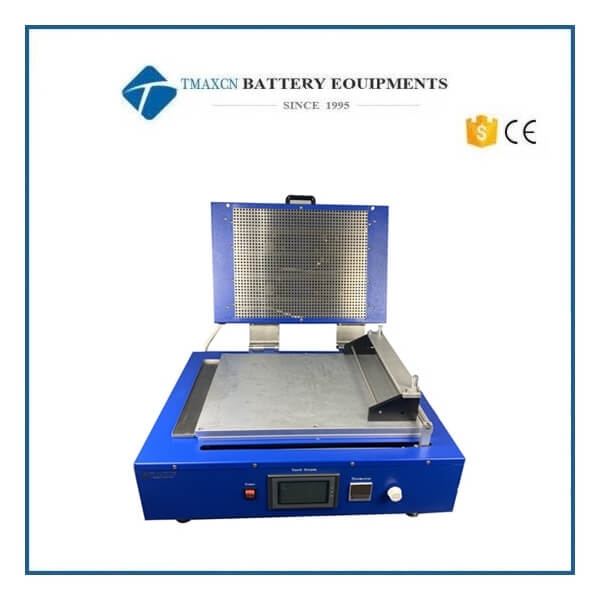

Laboratory Doctor Blade Film Coater Coating Machine with Heat and Vacuum Function

Model Number:

TMAX-TMHDimension(L*W*H):

550mm x 330mmx 320mmNet Weight:

45-80kgCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Micrometer Film Applicator with Adjustable Width 0 - 150 mmNext:

Lab Large Automatic Film Coater with Vacuum Chuck and Adjustable Doctor Blade

Laboratory Doctor Blade Film Coater Coating Machine with Heat and Vacuum Function

The automatic coating machine is widely used in high-temperature coating research, such as ceramic films, crystal films, battery material films, and specialized nano-films. It is designed to meet the scientific and technological advancements required for film formation under high-temperature conditions.

Key Features

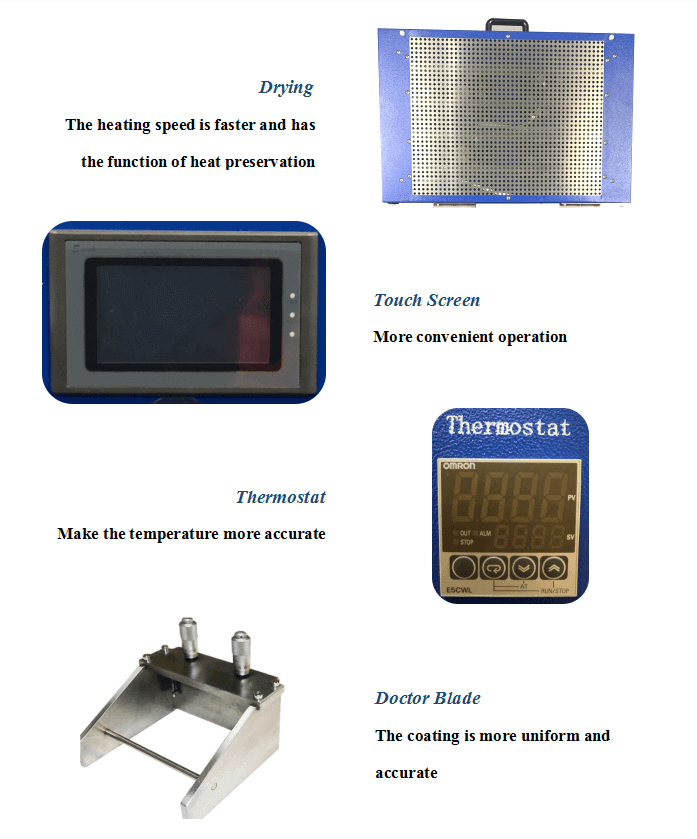

· Large-area uniform heating, ensuring high-precision temperature consistency inside the chamber.

· Flat coating mechanism, with motor-driven blade coating for stable and adjustable coating speed.

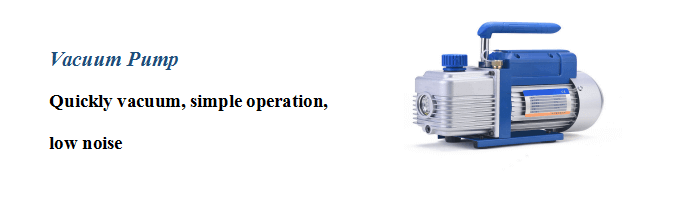

· Adjustable coating speed, with a vacuum aluminum plate for quick placement and removal of copper foil, aluminum foil, etc.. The system includes a built-in vacuum pump or an external vacuum source connection, ensuring secure substrate adhesion without deformation.

· Standard film applicator included, offering high coating accuracy and adjustable coating thickness.

· Compact design for glove box compatibility, allowing convenient operation and space-saving installation.

· PLC touchscreen control, enabling easy parameter adjustments.

Technical Specifications

Model |

TMH250 |

TMH300 |

TMH350 |

TMH550 |

TMH800 |

TMHXXX |

Effective Coating Size |

100*250mm |

200*300mm |

250*350mm |

250*550mm |

250*800mm |

customized |

Machine Weight |

80kg |

100kg |

115kg |

130kg |

160kg |

N/A |

Accessories: Film Applicator |

40um一5mm coating thickness applicator is included Or customized |

|||||

Heating & Drying System |

Included |

|||||

Optional Heating Cover Voltage and Power |

110VAC or 220VAC |

|||||

Traverse Speed |

0 - 100 mm/sec variable Accuracy: 10mm/sec |

|||||

Vacuum Pump |

Vacuum pump is included |

|||||

Heating Cover |

1. Pre-installed on the top cover 2. Built in digital temperature controller with accuracy of +/-1°C 3. Suspension support helps open cover easily and safely 4. Max. Heating Temp: 200°C |

|||||

Compliance |

CE Certificate |

|||||

Warranty |

One years limited warranty with lifetime support |

|||||

Operating procedures |

1. Put the Electrode on the vacuum plate, start the power supply, open the vacuum, the electrode adsorption on the vacuum plate. 2. Place the film applicator on the electrode and add the coating slurry. 3. Open the film, the film device automatically pushes the film applicator to move, automatic film. 4. Take out the film applicator and push rod, cover with the heating cap, set the heating temperature and time, and heat and dry. 5. After drying, open the heat cover, take out the coated film electrode, film device reset complete. |

|||||

Maintenance method and matters needing attention |

1. Every time before work to use a soft cloth with alcohol carefully wipe the film head, the body, keep clean. 2. Film head, differentiator and other high-precision parts of the use do not collide, gently take gently, differentiator to adjust the left and right to be symmetrical and even. 3. Regularly check screws, nuts, pins and other fasteners in various parts to prevent looseness and prevent product quality accidents. |

|||||

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com