products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Laboratory NMP Solvent Recovery System (8000M³/H) for Prismatic Battery Production

Model Number:

TMAX-8000SL-ICompliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Die Cutter Machine With Roll To Roll System For Lithium Battery Electrode CuttingNext:

Die Cutting Machine Electrode Sheet Coil Slitting Machine with Continuous Coating

Laboratory NMP Solvent Recovery System (8000M³/H) for Prismatic Battery Production

Configuration List

Component Name |

Model |

Quantity |

Remarks |

NMP Solvent Recovery System |

TMAX-8000SL-I |

1 set |

Recovery Rate: 99% ±3% Recovery Concentration: ≥80% Purification Concentration: <50 mg/m³ |

Built-in Spray Tower |

TMAX-PLT |

1 set |

|

Cooling Water Tower |

TMAX-30T |

1 set |

|

Liquid Storage Tank |

TMAX-CYG |

1 unit |

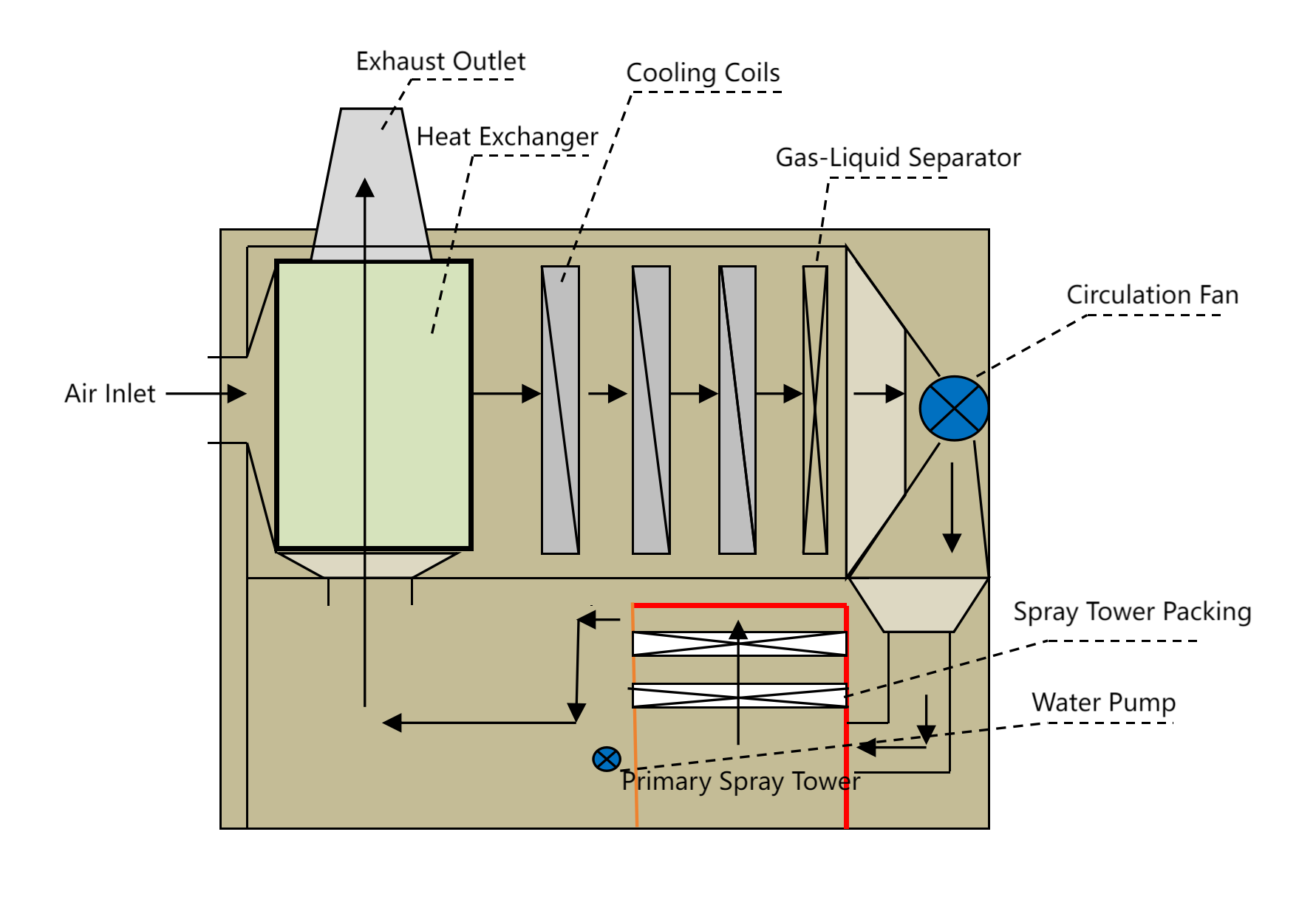

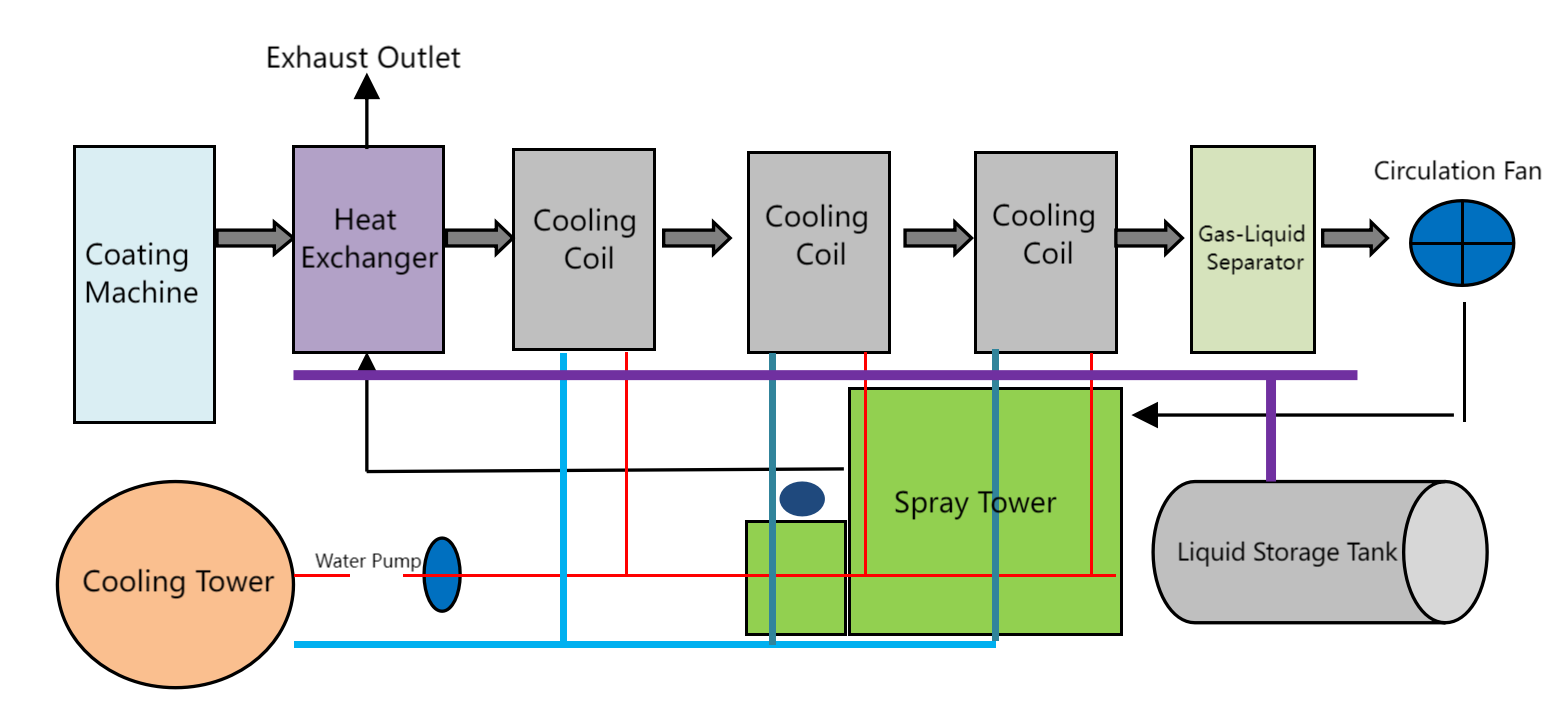

System Principle

This system is used for recovering N-Methyl-2-pyrrolidone (NMP) from exhaust gases emitted by lithium-ion battery coaters. With low energy consumption, it cools the gas using circulating water and demists the exhaust before release. The final emission concentration is far below the national emission standards, ensuring environmental compliance, energy savings, and material reuse.

Application

TMAX Series systems are designed for the lithium ion battery industry, particularly for handling NMP exhaust during the coating process.

Features

· Combines water-cooling and spraying for efficient NMP gas treatment and purification.

· Simple operation with clear indicators.

· Modular design, easy to disassemble for maintenance.

· Efficient recovery, yielding high economic benefits for users.

Technical Specifications

Parameter |

Specification |

Organic Compound Emission Level |

<50 mg/m³ |

NMP Recovery Rate |

99% ±3% |

NMP Recovery Concentration |

≥80% |

Environmental Requirements

· Ambient Temperature: +10~+40℃

· Relative Humidity: 20~90%

· Altitude: <1000 m

· Exhaust Gas Temperature: <120℃

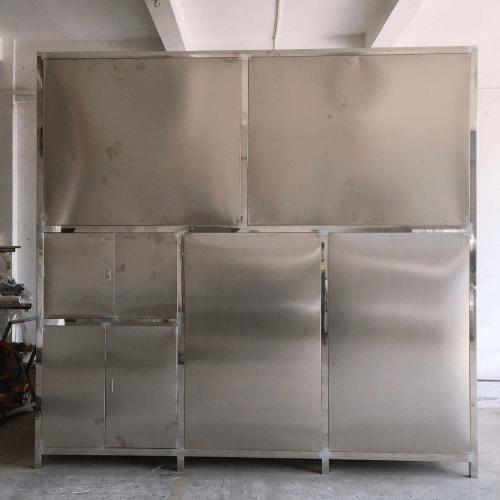

Machine Layout

Key Component Specifications

No. |

Assembly |

Part Name |

Material |

Size/Model |

Manufacturer |

1 |

Main Unit |

Heat Exchanger |

Aluminum Tubes |

800×800×350 |

TMAX |

2-4 |

Main Unit |

Fin Cooler |

Copper & Aluminum |

800×800×200 (×3) |

ASD |

5 |

Main Unit |

Gas-Liquid Separator |

304 SS |

800×800×50 |

TMAX |

6 |

Main Unit |

Induced Fan |

Stainless Steel |

3kW |

Aozhong/Xinfeng |

7 |

Main Unit |

Casing |

201 SS |

1.5mm |

TMAX |

8-9 |

Outer Frame |

Structural Parts |

201 SS |

50×50×3 / 1.0mm |

Hongercheng/Dahua |

10 |

Spray Tower |

Tower Body |

201 SS |

1200×1000×1700×1.5mm |

Hongercheng/Dahua |

11 |

Spray Tower |

Packing |

304 SS |

800×800 |

TMAX |

12 |

Spray Tower |

Nozzle |

316 SS |

DN10 |

TMAX |

13 |

Water Pump |

Circulating Pump |

Anti-corrosive |

1.5 kW |

Yuanli |

14-15 |

Cooling System |

Cooling Tower / Fan |

Fiberglass / Cast Iron |

30T / 1.5kW |

Liangyuan |

16 |

Cooling System |

Circulating Pump |

Anti-corrosive |

2.2 kW |

Yuanli |

17 |

Liquid Storage |

Drainage Pipe |

Aluminum-Plastic |

2.0 |

Zeke |

18 |

Liquid Storage |

Storage Tank |

201 SS |

1.5T |

TMAX |

Control System Configuration

No. |

Item |

Model |

Qty |

Brand |

1 |

Air Switch |

4P/32A |

1 |

Chint |

2 |

Single Pole Switch |

1P/10A |

2 |

Chint |

3 |

AC Contactor |

1210 |

3 |

Chint |

4 |

Thermal Relay |

4A/6A |

3 |

Chint |

5 |

Indicator Light |

Red, Green |

2 |

Chint |

6 |

Selector Switch |

NP2 |

2 |

Chint |

7 |

Fuse |

6A |

1 set |

Chint |

8 |

Thermostat |

18/H |

2 |

Chint |

9 |

Alarm Light |

Ad16-22sm |

1 |

Chint |

10 |

Control Cabinet |

400×500×200 / 400×400×1500 |

1 each |

Chint |

Equipment Power Configuration

Component |

Power |

Circulating Fan |

3 kW |

Circulating Water Pump |

2.2 kW |

Cooling Tower |

1.5 kW |

Spray Pump |

1.5 kW |

Liquid Pump |

0.55 kW |

Total |

8.75 kW |

Picture for reference

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com