products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

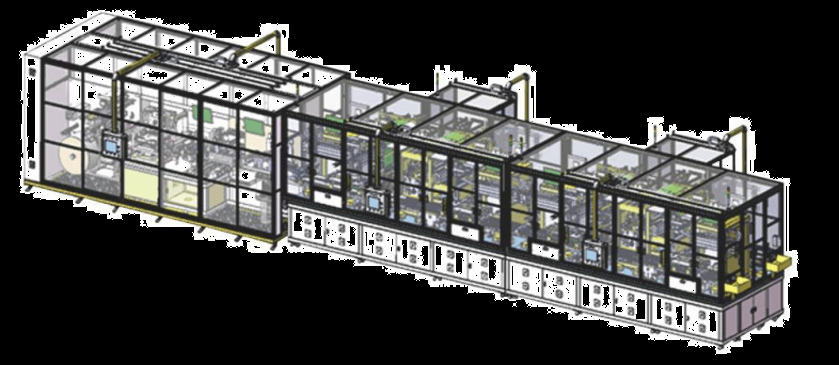

Li-ion Battery Cutting And Stacking All-in-One Machine

Model Number:

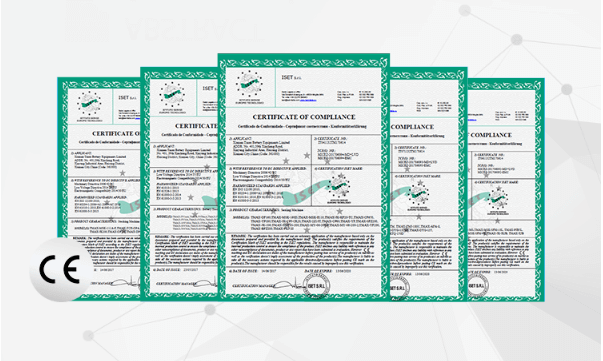

TMAX-ZTH-05Compliance:

CE CertifiedWarranty:

1 yearMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Fully Automated Battery Manufacturing Conveyor LineNext:

Dual-Station Fully Automatic Lithium-ion Battery Stacking Machine

Li-ion Battery Cutting And Stacking All-in-One Machine

Feature

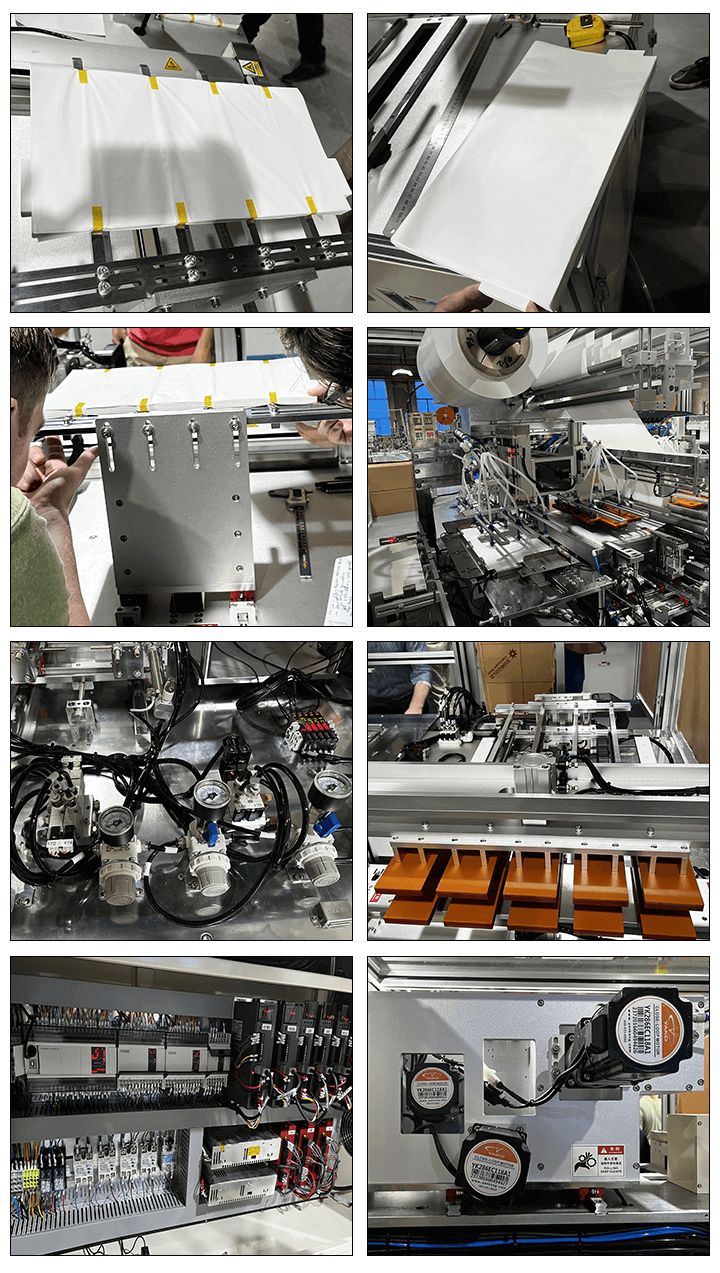

This equipment is mainly used for automatic unwinding, automatic deflection, tension control, CCD defect detection, driving, cutting and forming rounded corners, iron and dust removal, CCD size detection, NG rejection, vacuum belt conveying, CCD pre-positioning, diaphragm unwinding, stacking table according to the set number of layers into cores, diaphragm cutting and gluing, discharging, etc.; the final cores are loaded in pallets and can be Docking automatic logistics line and MES system, etc.

Specification

Project |

Parameters |

Positioning method |

CCD positioning |

Stacking efficiency |

Single station 0.6(whole machine 0.2)s/pcs |

Auxiliary time |

<10s |

Burr size |

Va≤12um ; Vbs12um |

Die life |

1. Can be used ≥ 1,500,000 times after each mold repair; 2. Mold can be repaired ≥ 10 times. |

Alignment accuracy between poles and diaphragm |

Centre deviation ±0.3mm |

Diaphragm end-face alignment accuracy |

±0.4mm |

Alignment accuracy between adjacent diaphragms |

±0.3mm |

Overall alignment accuracy |

King 0.5mm |

Number of laminations |

Settable within the thickness adaptation range |

Outer diaphragm |

No tail roll |

Die-cutting pass rate |

≥99.5% |

Qualified rate of laminations |

≥99.5% |

Overall machine qualification rate |

≥99% |

Cranking rate |

≥98% |

Dimension |

W13000mm x L5000mm x H2700mm |

Weight/load |

Approx. 35000Kg; >800Kg/M-2 |

Power supply |

AC380V three-phase;voltage fluctuation±10%;power:120KW;frequency:50Hz |

Compressed air |

0.5~0.7Mpa(5~7kgf/cm2),dosage 3000L/min |

Item |

Specification |

|

Punching method |

Hardware Die Punching |

|

Material system |

Continuous coated pole rolls with formed pole lugs |

|

Roll diameter |

≤∮800mm |

|

Inner diameter of reel |

3"/6" |

|

Pole winding error |

士2mm |

|

Serpentine bend error |

1mm/m |

|

Difference in height of wavy edge |

<2mm |

|

Thickness T |

5~20mm |

|

Width W |

80~200mm |

|

Length L |

120~300mm |

|

Length L1 of the tabs |

10~30mm |

|

Orientation of the tabs |

Ipsilateral/heterolateral |

Production Assembly Plant

Detailed Images

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com