products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

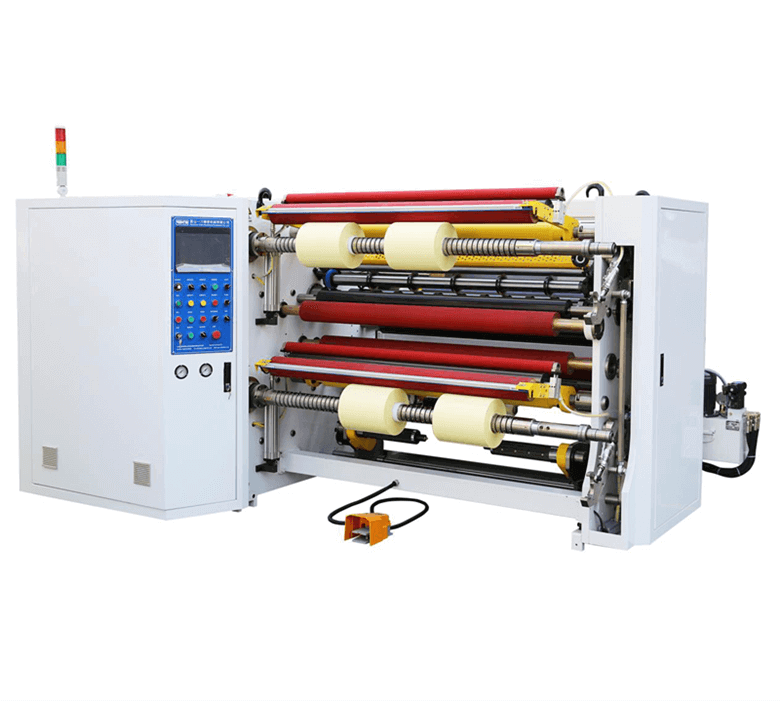

Lithium-ion Battery Roll to Roll Battery Electrode Slitting Machine with 15–380mm Width Slitting

Model Number:

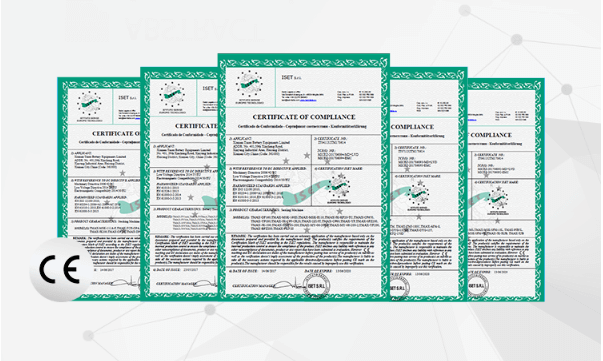

TMAX-XFT550ACompliance:

CE CertifiedWarranty:

One year limited warranty and lifetime supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Automatic Thin Film Separator Slitter Slitting Machine With Roll to Roll SystemNext:

Laboratory Cylindrical/Pouch Cell Battery Electrode Slitting Machine

Lithium-ion Battery Roll to Roll Battery Electrode Slitting Machine with 15–380mm Width Slitting

I. Equipment Overview

1.1 Function Description

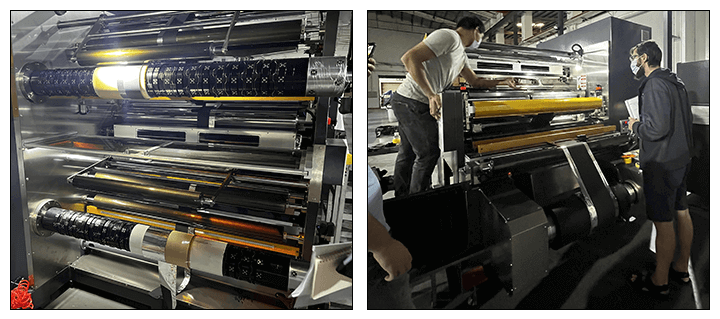

The Slitting Machine is mainly designed for slitting electrode sheets of lithium-ion batteries. As a mature and stable model, it has been widely adopted by our company. It supports a slitting width range of 15–380 mm, features user-friendly operation, and meets diverse slitting process needs. Equipped with a dual-shaft rewinding structure, the machine works as follows: the electrode sheet is mounted on the unwind shaft, passively unwound via the drive roller, and automatically guided. After passing through the slitting blades and iron powder removal unit, the electrode sheet is slit and rewound in line with process requirements. This machine is easy to operate, with simple loading and threading procedures, delivering stable performance and superior slitting outcomes.

1.2 Key Technical Parameters

· Production Capacity: Max mechanical speed is 80 m/min; typical production speed is 0.5–50 m/min with stepless adjustment.

· Rewinding Alignment Accuracy: ≤ ±0.5 mm (assuming good incoming material quality).

· Pass Rate: ≥ 99% (excluding factors such as poor incoming material).

· Utilization Rate: ≥ 95% (excluding material replacement and incoming quality issues).

Table 1.1 Main Components List

No. |

Component Name |

Description |

Quantity (sets) |

1 |

Main Frame Assembly |

Electrical cabinet, side plates, mounting panels |

1 |

2 |

Unwinding Unit |

Air-expanding shaft, tension roller, locking cylinder, web guiding unit |

1 |

3 |

Splicing Platform |

Pressure cylinder, pressure bar, splicing platform |

1 |

4 |

Unwind Tension Unit |

Tension controller, sensors, rollers |

1 |

5 |

Drive Unit |

Motor, drive roller, press roller, pressure adjustment system |

1 |

6 |

Adjustment Roller Unit |

Pre-slitting and post-slitting upper/lower adjustment rollers |

3 |

7 |

Knife Holder Assembly |

Upper and lower knife shafts, adjustment rollers, drive, dust removal |

1 |

8 |

Dust Removal Unit |

Blade dust removal and electrode powder brushing with 8 brush boxes |

2 |

9 |

Iron Removal Unit |

Magnetic bars and holders, magnetic strength 6000 Gauss |

4 |

10 |

Pressing Belt Unit |

Upper and lower pressing belt structures |

1 |

11 |

Rewind Tension Unit |

Upper/lower tension systems and sensors |

1 |

12 |

Tracking Roller Unit |

Upper and lower tracking rollers |

1 |

13 |

Rewind Unit |

Slip shafts, pressure rollers, motors |

2 |

14 |

Edge Trim Unit |

Guide rollers, pressure rollers, waste bins |

1 |

1.4 Equipment Workflow

The equipment workflow is as follows:

Web Threading Steps:

1. Load materials onto the unwind shaft using a transfer cart.

2. Manually thread the electrode sheet through the splicing unit.

3. Guide it through the tension system.

4. Manually feed the sheet to the slitting blades for pre-slitting.

5. Pass the pre-slit sheet through the dust and iron removal system.

6. Mount the core sleeve onto the slip shaft.

7. Tape the electrode sheet to the core sleeve on the slip shaft.

8. Adjust the sheet tension to the required level.

9. Switch the web guiding system to automatic mode.

10. Press the system start button.

11. The equipment automatically slits the material and rewinds it into rolls.

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com