products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

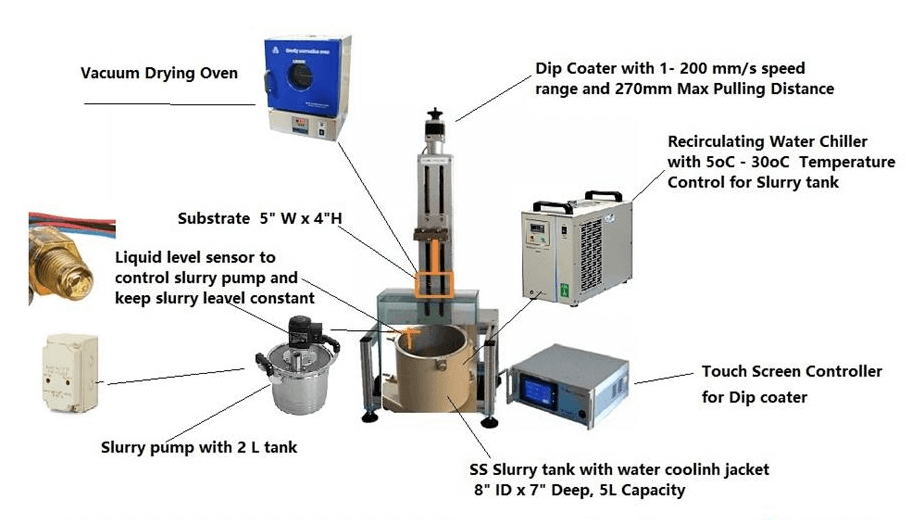

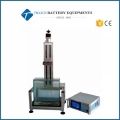

PLC Controlled Dip Coater (1-200 mm/min) for Large Substrate up to 10"x12"

Model Number:

PTL-200Dimension(L*W*H):

310mm(L) x 260mm(W) x (1-5)mm(Thickness)Net Weight:

20kgCompliance:

CE CertifiedWarranty:

Two Years limited warranty with lifetime supportShipping Port:

XiamenPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Dip Coater (1-200 mm/min) with Drying Oven up to 100°CNext:

Programmable Control Vertical Dip Coater

PLC Controlled Dip Coater (1-200 mm/min) for Large Substrate Up to 10"x12"

Working Voltage |

110/220V AC switchable, 50/60 Hz |

Max. Power Consumption |

20W |

Max Stroke Length |

300mm |

Maximum Sample Load |

7 kg (15.4 lbs) |

Standand Panel Size |

· 310mm(L) x 260mm(W) x (1-5)mm(Thickness) |

Panel Holder |

Can hold one or several panels from 1-5mm thickness |

Touch Screen PLC Dimensions |

6"(L) x 4"(W) |

Insertion Speed |

1 - 200 mm/minute programmable by Touch Screen PLC |

Withdrawal Speed |

1 - 200 mm/minute programmable by Touch Screen PLC |

Max. Dry and Dwell time |

999s |

Max. Travel Distance |

270mm |

Max. Number of Cycles |

20 |

Speed Stability |

+/- 0.05% |

Immersion Tank |

1 Material: Polypropylene |

Product Dimensions |

409mm(L) x 356mm(W) x 1000mm(H) |

Compliance |

CE Certified |

Warranty |

Two Years limited warranty with lifetime support |

Application Notes |

1 In order to get better film coating, the substrate shall be treated by plasma cleaner |

Net Weight |

20 kg |

Shipping Weight & Dimension |

48" x 40" x 46", 155 lb |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com