products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Prismatic Cell Battery PVC Blue Film Covering Machine

Model Number:

TMAX-TMJ-05Compliance:

CE CertifiedWarranty:

One years limited warranty with lifetime technical supportPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Battery Tab Shaping Press&Cutting Machine for Prismatic CellNext:

Laboratory Battery Laser Welding Machine For Top Case Welding

Prismatic Cell Battery PVC Blue Film Covering Machine

1、 Equipment Overview:

This device is suitable for applying film on the appearance of prismatic cell, covering and pasting a layer of insulation adhesive on the entire surface of the battery cell, which can better protect the battery cell and prevent short circuits. Manually load and collect battery cells.

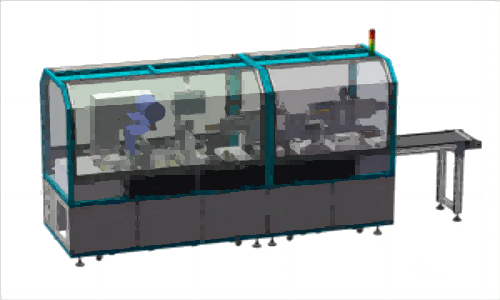

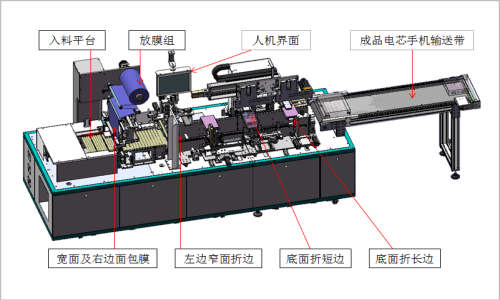

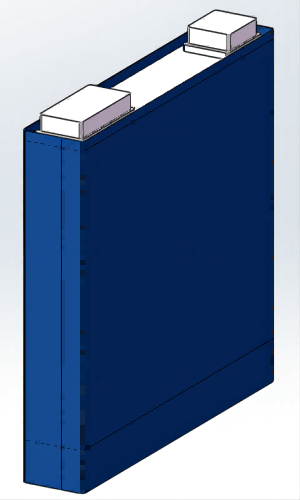

1.1 Complete machine diagram

(The outer garment of the machine is made of aluminum profiles and acrylic)

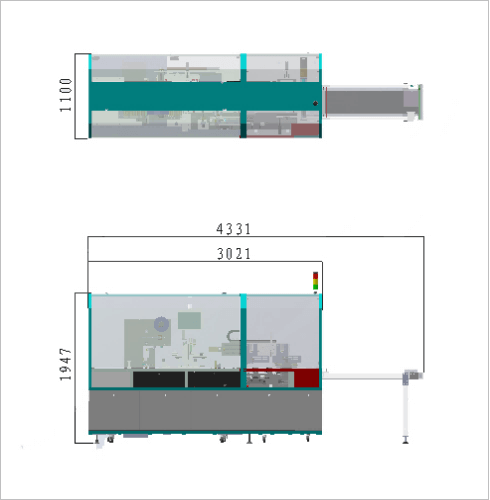

1.2 External dimensions

L4350mm × W1100mm × H1950mm

1.3 Principle and Effect of Adhesive Packaging:

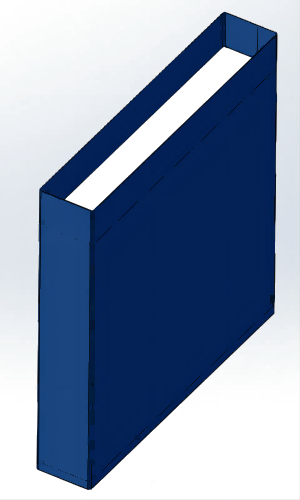

1.3.1 Wrap the adhesive film along the height direction of the battery on all four sides and seal the edges on the side (as shown in Figures 1 and 2)

(Figure 1) (Figure 2)

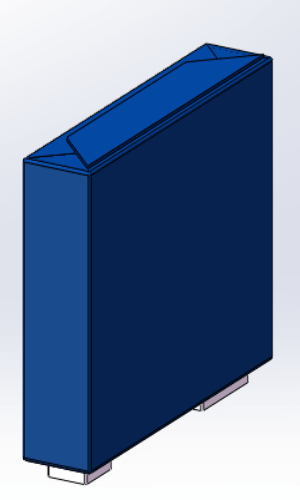

1.3.2 The bottom of the battery is sealed in a "Y" shape, with the short edge first and then the long edge (as shown in Figure 3)

(Figure 3)

1.4 Process characteristics

1.4.1 Adjustable size, adjustable range: 85mm~220mm (height) * 130mm~180mm (width) * 20mm~60mm (thickness)

1.4.2 Bubbles inside the wrap: no wrinkles, no indentation, no flipping, no damage; Bubbles ≤ 5mm, number of bubbles on each front side ≤ 5, and number of bubbles on each side ≤ 3; Do not damage the battery or scratch the insulation film during the coating process;

1.4.3 Wrapping accuracy: ± 0.5mm (the surface of the battery cannot be left blank); Adjustable overlap: 5mm-10mm

1.4.4 Insulate the parts that come into contact with the battery to prevent short circuits and scratches;

1.5 Incoming Material:

Insulation film/adhesive: according to customer's requirements

1.6 Institutional characteristics

1.6.1 The part in contact with the battery is designed with non-metallic materials;

1.6.2 Any part in contact with the battery shall have short-circuit protection, emergency stop protection, and power/gas off protection functions;

1.6.3 Coating action does not damage the battery;

1.6.4 The contact area with the battery shall be made of non-metallic materials;

1.6.5 Equipment operation status display (three color light);

1.6.6 Leave sufficient maintenance and repair space for the entire equipment and vulnerable parts.

2、 Technical parameters

No |

Item |

Technical specifications |

1 |

Overall dimensions |

4350mm long × 1100mm wide × 1950mm (high) (equipment dimensions may vary depending on cell specifications) |

2 |

Equipment weight |

800Kgs |

3 |

Rated power |

3.5kw |

4 |

Compressed air |

5kgf-7kgf/c ㎡ (0.5Mp-0.7Mp) dry, anhydrous |

5 |

Efficiency |

4-6 PPM (designed with blue battery capacity of 54153173) |

6 |

Product qualification rate |

≥ 99.5% |

7 |

Equipment failure rate |

≤ 2% (only equipment caused faults) |

8 |

Cell specifications |

Blue cell size: 173.5mm (height) * 153.5mm (width) * 53.5mm (thickness) Compatibility: |

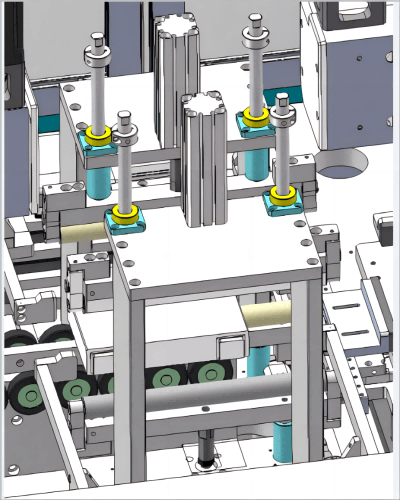

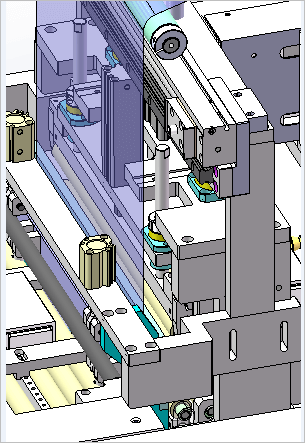

3、 Equipment component structure

3.1 Manual feeding

Manually place the battery cells on the feeding table, use a cylinder to automatically correct the battery cells, and push the battery cells to the next workstation through a servo motor.

(Figure 4)

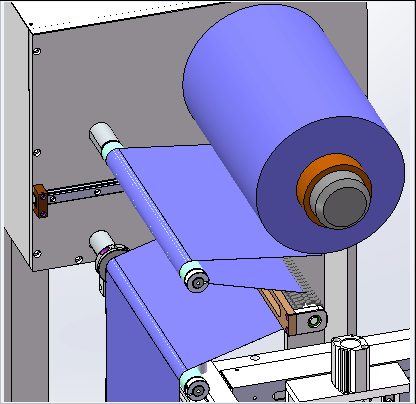

3.2 Blue film release mechanism

The blue film is unwinded through a tension mechanism to achieve smooth unwinding

(Figure 5)

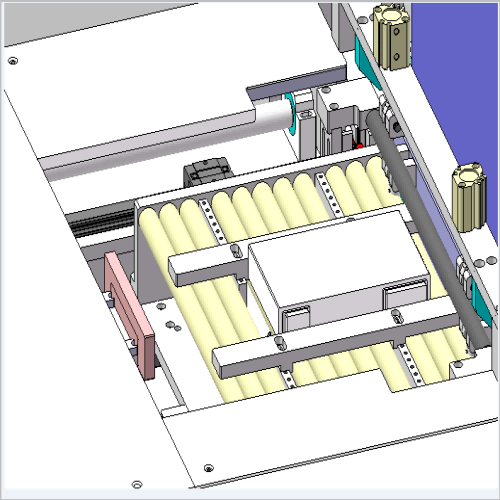

3.3 Wide and narrow side blue film wrapping mechanism

Using servo push cells, the film pulling, wrapping, and cutting actions are completed through cylinders, servo, and precision mechanisms to achieve wide and narrow blue films.

(Figure 6)

3.4 Bottom folding

Using precision fixtures to position the battery cell, combined with a cylinder folding mechanism to complete the bottom folding of the battery cell (excluding the top folding).

(Figure 7)

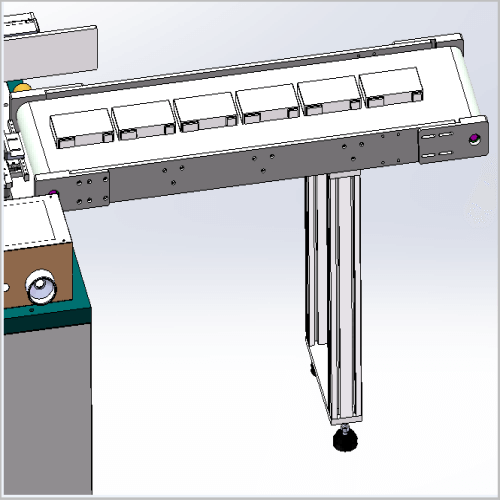

3.5 Cell Collection Structure (Figure 8)

By driving the belt through the motor, neatly arrange and collect the battery cells one by one.

(Figure 8)

4、 Equipment usage environment

No |

Item |

Technical specifications |

Note |

1 |

source |

AC220V 50/60HZ |

|

2 |

Rated power |

3.5kw |

|

3 |

compressed air |

5kgf-7kgf/c ㎡ (0.5Mp-0.7Mp) dry, anhydrous |

|

4 |

relative humidity |

20-75% HR |

|

5 |

Environmental cleanliness |

No corrosive gases, liquids, or explosive gases on site |

|

6 |

Rated power |

3.5kw |

|

7 |

Bottom bearing capacity |

≥ 500KG/m ² |

|

5、 Main component brands

No |

Name |

Brand |

Place of origin |

1 |

Servo motor |

Xinjie |

China |

2 |

Stepper motor |

Research and control, Lei Sai |

China |

3 |

PLC |

Xinjie |

China |

4 |

Man-machine interface |

Kunlun, Weiluntong |

China |

5 |

Air conditioning combination |

AIRTAC |

Taiwan |

6 |

Switch |

IDEC |

Japan |

7 |

Siemens |

Germany |

|

8 |

chint |

China |

|

9 |

SCHNEIDER |

France |

|

10 |

pneumatic components |

AIRTAC |

Taiwan |

11 |

Flow limiting valve |

AIRTAC |

Taiwan |

12 |

SMC |

Japan |

|

13 |

pressure reducing valve |

SMC |

Japan |

14 |

AIRTAC |

Taiwan |

|

15 |

Proximity switch |

SUNX |

Japan |

16 |

Magnetic ring switch |

AIRTAC |

Taiwan |

17 |

Linear guide slider |

HIWIN |

Taiwan |

18 |

TBI |

Taiwan |

|

19 |

CSK |

Taiwan |

|

20 |

Ball screw |

HIWIN |

Taiwan |

21 |

TBI |

Taiwan |

|

22 |

CSK |

Taiwan |

|

23 |

Photoelectric switch |

Panasonic, Omron, Keyence |

Japan |

24 |

Vacuum detection |

AIRTAC |

Taiwan |

25 |

bearing |

NSK |

Japan |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com