products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

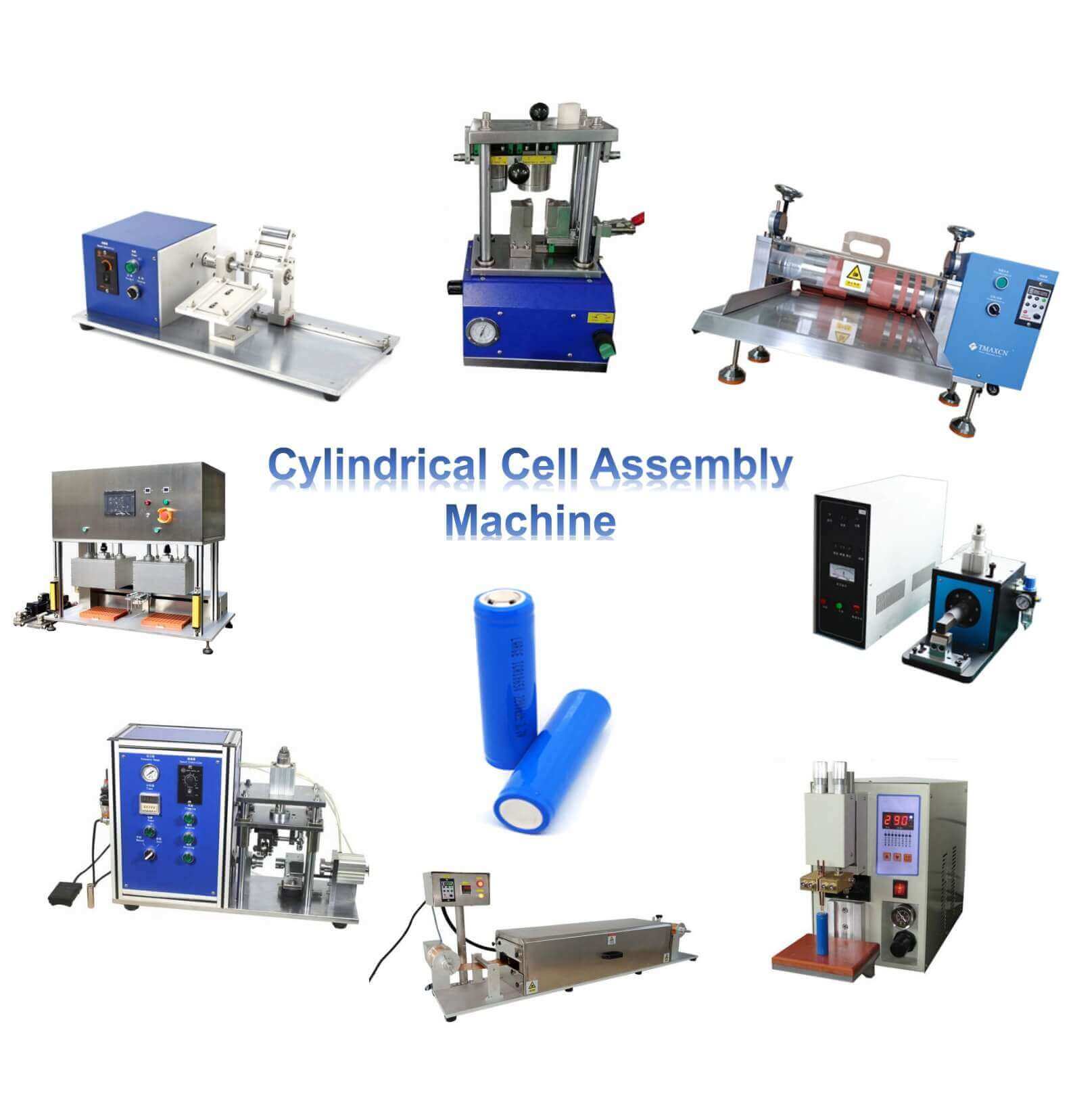

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

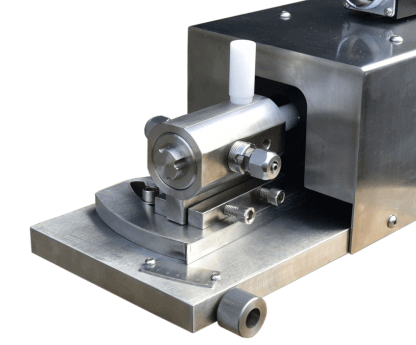

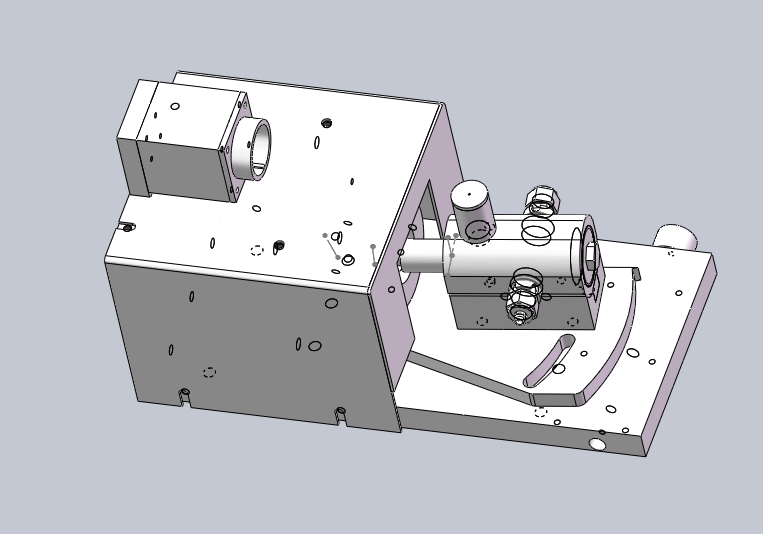

Programmable Precision Battery Electrolyte Filling Machine Filling Pump System

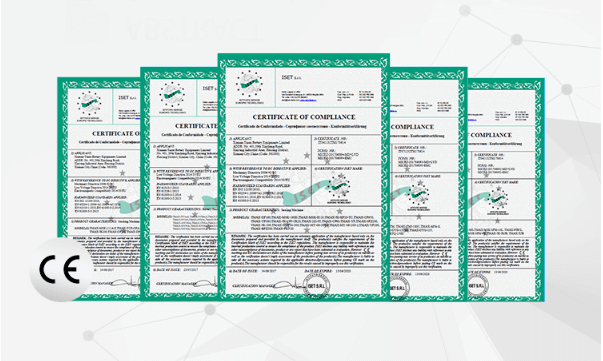

Model Number:

TMAX-ZBZCompliance:

CE CertifiedPayment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Programmable Precision Battery Electrolyte Filling Machine Filling Pump System

It is suitable for high-end micro liquid precision filling/injection, such as medicine, electrolyte, acid, solvent, dairy products, glue, reagent and other industries.

Working principle

The high precision electric filling pump uses the connection between the coupling and the stepping motor to drive the reciprocating rotation of the plunger rod in the ceramic cavity, forming a reciprocating valve direction switch between the liquid inlet and the liquid outlet. So as to achieve the goal of precise control of liquid medium inlet and outlet.

Working process

Preparation of power supply and liquid medium → plunger rod rotates to suck liquid into cavity → plunger rod rotates through liquid inlet and closes liquid inlet → plunger rod continues to rotate to discharge chamber working fluid → plunger rod rotates to close liquid outlet.

Main features

1. Suitable for high-end micro precision liquid medium metering filling, adding, liquid injection, spraying, marking. The valve less design is adopted, the flow rate is extremely stable, and the flow accuracy is within ± 3 ‰.

2. The pump core is made of special industrial ceramics (zirconia, alumina aluminum), which has the excellent characteristics of high strength wear resistance, acid-base corrosion resistance, high temperature resistance and long service life.

3. It has anti chemical reaction, and the contact medium part is ceramic.

4. the core and the pump sleeve are made of the most advanced nanotechnology and gelcasting technology, with uniform microstructure and high density. High precision matching, self sealing, self lubricating ceramic technology, no need for additional seals and lubricants.

5. The pump sleeve and component mechanism are even, with acid and alkali resistance, and can be used in various harsh liquid occasions.

6. The design structure is positive displacement plunger structure, reciprocating rotation operation, adjusting stroke length / rotation cycle to change the flow size.

7. No waste, no bubble, no leakage, no liquid point and no blockage.

8. The system has powerful functions, multi capacity and multi speed selection, which can transform and reverse transfer liquid.

9. There is no dynamic seal and wearing parts, and the only moving part is plunger rod, which is easy to maintain.

10. It adopts imported programmable controller and touch screen for man-machine dialogue, convenient parameter setting and stable and reliable performance.

11. It can measure and inject liquid according to the set parameters, and automatically stop measuring when the specified liquid quantity is reached.

12. Standard communication interface, which can be used independently or communicate with PLC or IPC conveniently.

13. According to the actual production, the total amount of liquid can be: Q Total (total liquid measurement) = Q stroke (stroke amount) * N stroke (stroke number)

14. It has the function mode of forward pumping, back pumping, delayed metering, standby cleaning and capacity counting.

15. The whole machine is compact in appearance, elegant in appearance, flexible in use, simple in operation, stable in operation, safe and reliable in operation.

Specifications

Product type |

Industrial ceramic piston metering pump with single head, one outlet and one reciprocating positive displacement |

Pump core material |

ZrO₂、Al₂O₃ |

Pump core performance |

Corrosion resistance, high temperature resistance, wear resistance, high hardness, low friction coefficient and long service life |

Matching accuracy of pump core |

2μm |

Driving mode |

Imported servo motor / stepping motor |

Speed range |

1-1200rpm reversible |

Speed control mode |

Pulse |

Control and display mode |

4.3 inch touch screen human machine interface dialogue operation |

Programming software |

Imported Panasonic programmable controller |

Storage performance |

Permanent memory, can store parameters and up to 100 formulations |

Single stroke capacity range |

0μL-10000μL, max10000/1 stroke |

Capacity calculation method |

Q Total (total liquid volume) = Q stroke (stroke amount) × N stroke (stroke number) |

Measurement accuracy |

±0.5% |

Applicable medium temperature |

Medium liquid temperature≤250 ℃ (due to different materials, please indicate when placing an order) |

Catheter |

PE / Teflon inlet inner diameter is φ6, outer diameter is φ8, outlet inner diameter is φ6, outer diameter is φ8 |

Discharge needle |

φ2.5/φ4.0/φ6.0 (needle and needle length optional) |

Metering pump size |

L×W×H 201×125×147mm |

Controller size |

L×W×H 295×215×157mm |

Weight |

about 7.3kg, including controller and metering pump |

Applicable power supply |

AC 220 V±10%, 50 Hz/60 Hz (standard) AC 110 V ± 10%, 50 Hz / 60 Hz (optional) |

Work environment |

Temperature 0-40℃, relative humidity < 80% |

Protection level |

IP31 |

Safety performance |

Password protection and factory recovery function to ensure that the set parameters are not randomly modified |

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com