products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

PVD Thin Film Deposition Coating Machine System For Metals And Organics

Model Number:

TMAX-PD-ZD01Input Power:

2000WCompliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportShipping Port:

XiamenMOQ:

1Payment:

L/C D/A D/P T/T Western UnionDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Dual-Source Vacuum Deposition Coating System Evaporation CoaterNext:

Small Carbon Film Deposition Coater for SEM &EDS Sample Preparation

PVD Thin Film Deposition Coating Machine System For Metals And Organics

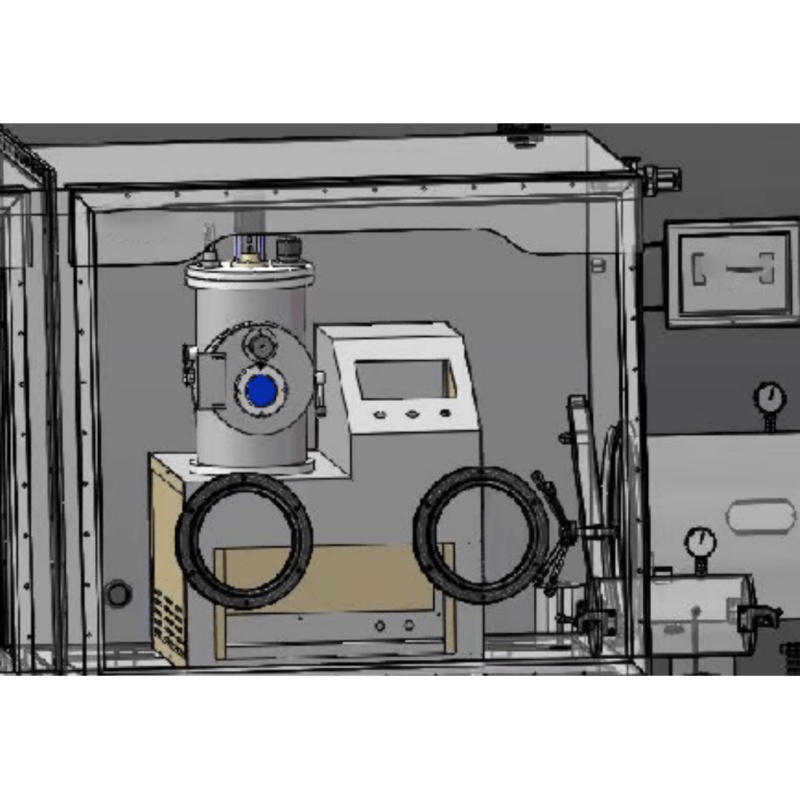

TMAX-PD-ZD01-High-Vacuum Evaporation Coating System

Product Overview

This system is a compact, multi-source high-vacuum evaporation coating platform designed for laboratory use, capable of depositing thin films of metals, organics, and other functional materials. It is ideal for:

· Research labs (metal electrode fabrication, SEM sample preparation).

· Advanced materials development (organic thin films).

· Process optimization (high-precision coatings for novel material synthesis).

Key Advantages vs. Competing Systems

Feature |

This System |

Typical Competing Systems |

Vacuum Speed |

15–20 min to high vacuum (≤5×10⁻⁵ Pa) |

Often 30+ min for similar vacuum levels. |

Film Uniformity |

±3%–5% thickness deviation |

Typically ±5%–10% in entry-level models. |

Chamber Material |

304 stainless steel (high corrosion resistance) |

Some use aluminum or lower-grade steel. |

Modularity |

Supports 1–3 evaporation sources (expandable) |

Fixed configurations common in low-end systems. |

Footprint |

Compact (500×360×420mm for desktop model) |

Larger benchtop units often >600×500mm. |

Technical Specifications

Parameter |

Specification |

Vacuum Chamber |

304 stainless steel, cylindrical (Φ260×H350 mm) |

Internal Coating Area |

~Φ260×H310 mm |

Ultimate Vacuum |

≤5×10⁻⁵ Pa |

Pumping Speed |

≤8×10⁻⁴ Pa in 30 min, holds ≤5 Pa for 12 hours |

Substrate Stage |

- Max size: 80×80 mm (standard) / 120 mm diameter (rotary) - Rotation: 0–20 RPM (magnetic fluid sealed) |

Film Uniformity |

<5% (120 mm diameter area) |

Evaporation Sources |

2–3 sources (metal/organic compatible, co-evaporation or switching) |

Power Supply |

2 kW, constant current/power modes |

Electrical |

AC 220 V / 50 Hz, 3.5 kW |

Dimensions (L×W×H) |

- Main unit: 600×500×900 mm - Desktop model: 500×360×420 mm |

Why This System Stands Out?

1. Speed & Efficiency

o Achieves high vacuum 50% faster than comparable models, reducing idle time.

2. Precision Engineering

o Stainless steel chamber + optimized gas paths ensure minimal contamination and long-term stability.

3. Flexible Configurations

o Modular design allows easy upgrades (e.g., adding a third evaporation source).

4. Space-Saving

o 30% smaller footprint than conventional systems, critical for crowded labs.

Ideal For:

✔ Universities studying thin-film physics.

✔ R&D centers developing flexible electronics or OLEDs.

✔ Industrial labs requiring high-repeatability coatings.

Order Note: Minimum 1 unit. Custom configurations available.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com