products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

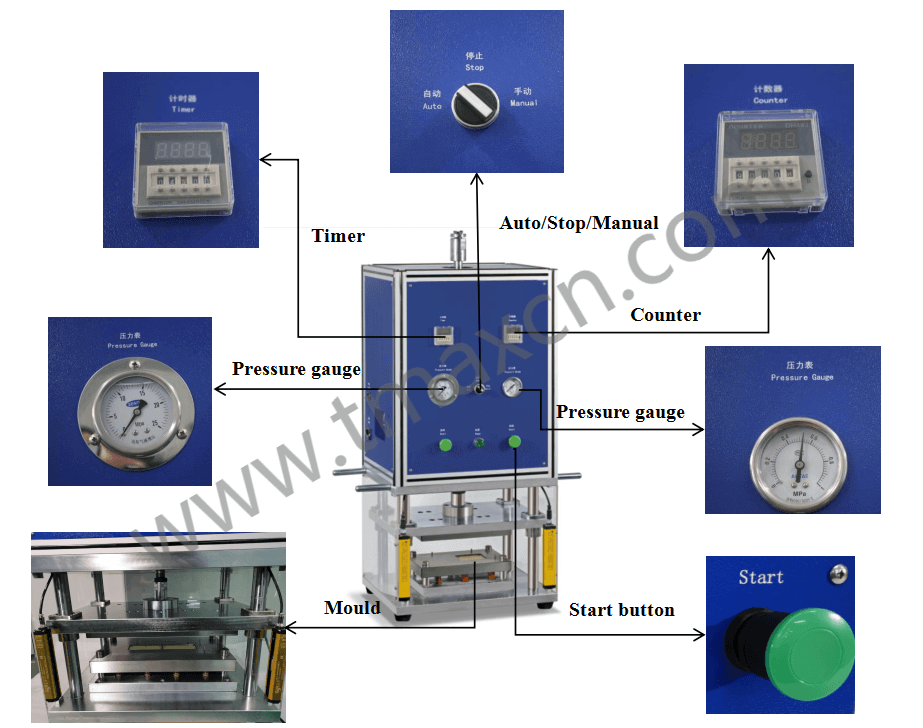

Solid State Battery Aluminum Laminated Film Punching Forming Machine

Model Number:

TMAX-SCK200Compliance:

CE CertifiedWarranty:

One Year limited warranty with lifetime supportDelivery Time:

5 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Previous:

Solid State Battery Hot Press MachineNext:

Solid State Battery Heat Sealer For Top&Side Sealing

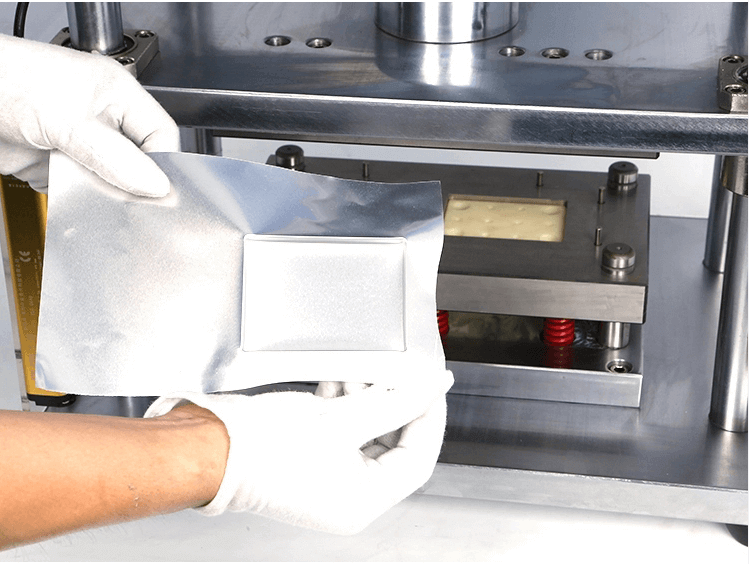

Solid State Battery Aluminum Laminated Film Punching Forming Machine

Application

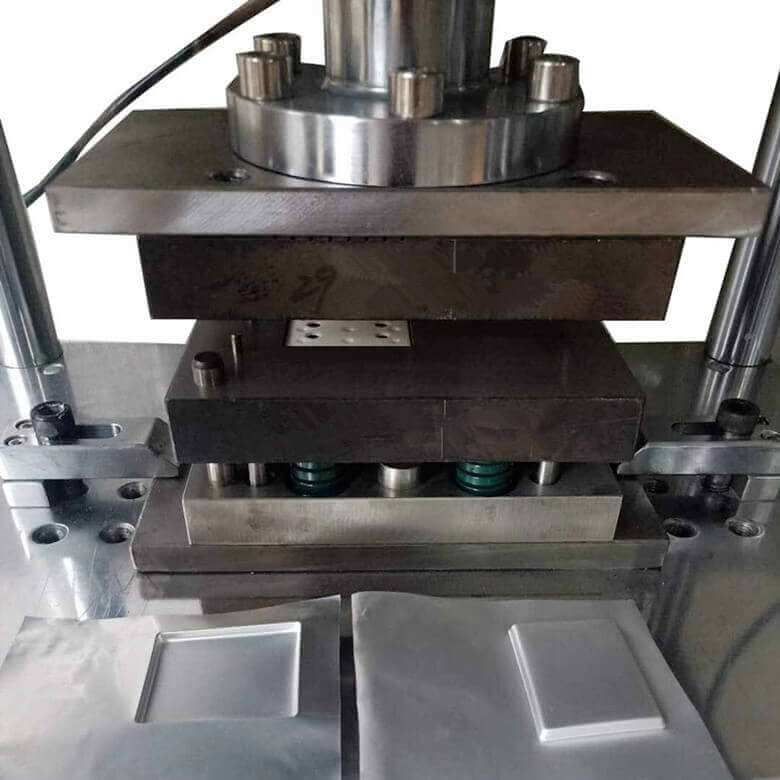

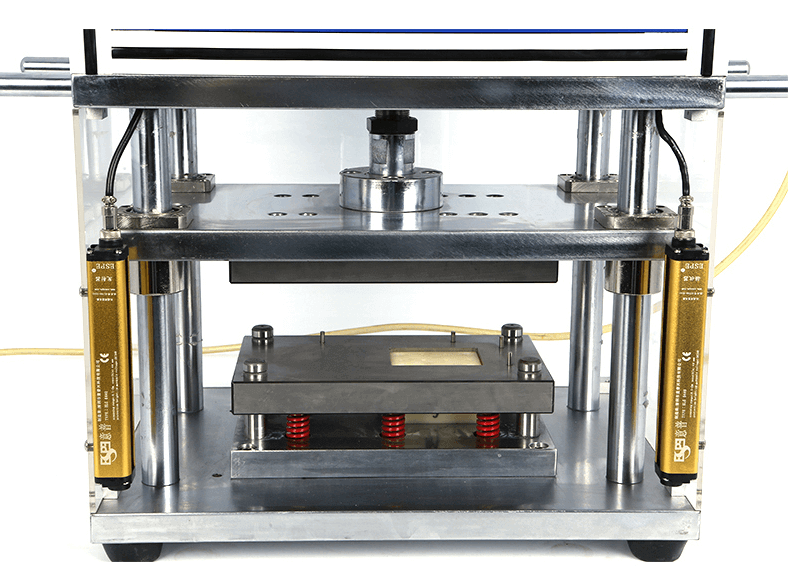

The TMAX-SCK200 is a semi-automatic pouch cell forming machine specifically designed for pouch cell aluminum-laminated film case forming. It utilizes a booster cylinder to convert low air pressure into high hydraulic output, driving the mold to shape the aluminum-laminated film into a case for pouch cell lithium batteries.

Key Features

· Quick and easy adjustment of forming depth.

· Fast mold replacement, enhancing operational efficiency.

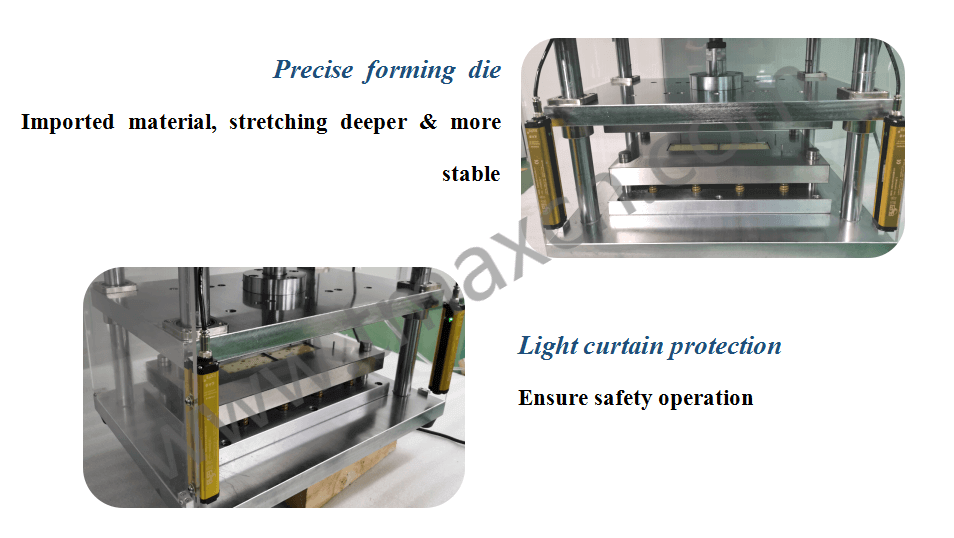

· No fish-tail or corner collapse after forming, ensuring clean product contours.

· Four-guide pillar structure for smooth and precise vertical motion.

· Safety ensured with light curtain, dual-button controls, and protective covers.

· Compared with similar machines, this model provides deeper and more stable forming results with equivalent film quality.

· Compact, safe, and user-friendly, suitable for lab or pilot production use.

Technical Specifications

Model |

TMAX-SCK200 |

TMAX-SCK300 |

Applicable Aluminum-laminated Film Size |

Max. L200mm × W150mm (customizable) |

Max. L300mm × W280mm (customizable) |

Booster Cylinder |

3T (adjustable) |

5T (adjustable) |

Counting Mode |

Digital counter display |

Digital counter display |

Power Supply |

AC220V / 50Hz |

AC220V / 50Hz |

Power Consumption |

100W |

100W |

Compressed Air Supply |

0.5–0.7MPa |

0.5–0.7MPa |

Machine Dimensions |

L460mm × W320mm × H925mm |

L560mm × W420mm × H925mm |

Machine Weight |

Approx. 180kg |

Approx. 210kg |

Mold/Mandrel Roughness |

Ra 0.4 |

Ra 0.4 (mirror polished) |

Upper/Lower Mold Flatness |

0.02mm |

0.02mm |

Mandrel Flatness |

0.02mm |

0.02mm |

Max. Forming Depth |

Max. 6mm (depends on film strength) |

Max. 6mm (depends on film strength) |

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com