products categories

- Battery Production Equipment Line

- Battery Lab Pilot Equipment Line

- Lithium Battery Pack Assembly Line

- Solid State Battery Assembly Line

- Sodium Ion Battery Production Line

- Supercapacitor Assembly Line

- Lithium Ion Battery Recycling Plant

- Dry Electrode Preparation Solution

- Perovskite Based Solar Cell Lab Line

- Li ion Battery Materials

- Cathode Active Materials

- Anode Active Materials

- Customized Battery Electrode

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Metal Mesh

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip

- Battery Tabs

- Graphene Materials

- Nickel Felt

- Titanium Fiber Felt

- Battery

- Battery Pack Machine & Compoments

- Battery Pack Compoments

- Turnkey Solutions Battery Pack Assembly Line

- Cell Sorter

- Battery Pack Spot Welder

- Laser Welder

- Battery Charging Discharging Tester

- Battery Pack Aging Machine

- Battery Pack Comprehensive Tester

- CCD Visual Inspector

- Battery Pape Sticking Machine

- BMS Testing Machine

- Al Wire Bonding Machine

- Lithium Battery Machine

- Battery Tester & Analyzer

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Spot Welding Machine

- Vacuum Mixer Machine

- Crimping/Disassembling Machine

- Vacuum Sealing Machine

- Electrolyte Filling

- Stacking/Winding Machine

- Electrode Cutter/Slitter

- Pouch Forming Machine

- NMP Solvent Treatment System

- Lithium Battery Production Plant

- Vacuum Glove Box

- Furnaces

- Coaters

- PVD Coater

- Laboratory Press Machine

- Large Press Machine

- Planetary Centrifugal Mixer

- Ball Mill

- Laboratory Machine

- Cutting Machine

- Metal Foam

contact us

- If you have questions, please contact us, all questions will be answered

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Add : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

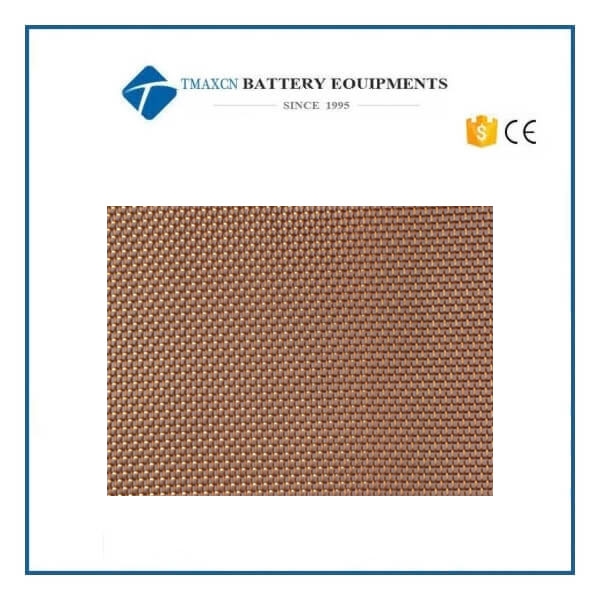

Stable Lithium Metal Anode with Metal Copper Mesh

Model Number:

TMAX-CUM01Compliance:

CE CertifiedDelivery Time:

2 days

- WhatsApp : +86 18659217588

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Wechat : 18659217588

Stable Lithium Metal Anode with Metal Copper Mesh

Introduction

With the continuous advancements in materials technology and characterization methods, lithium metal batteries (LMBs) have gained significant attention due to their high theoretical gravimetric capacity and low reduction potential. However, one major challenge hindering their widespread adoption is the formation of lithium dendrites during cycling, posing safety risks and leading to low Coulombic efficiency and capacity fading.

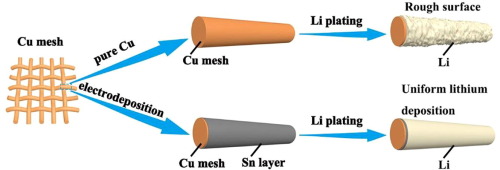

In addressing this issue, the utilization of copper mesh decorated with a cost-effective tin (Sn) layer emerges as a promising solution for a stable lithium metal anode. The copper mesh, modified with a lithiophilic Sn layer, demonstrates a reduced lithium nucleation overpotential, comparable to precious metals like gold (Au) and silver (Ag). This modification enhances the lithiophilicity of the substrate, promoting uniform lithium distribution and suppressing dendrite formation during the initial lithium plating process.

The incorporation of the Sn layer on the copper mesh creates a lithiophilic environment, facilitating the nucleation of lithium and forming a stable Li–Sn alloy during repeated plating and stripping cycles. As a result, the copper mesh decorated with Sn exhibits high Coulombic efficiency and superior cycling stability, offering a dendrite-free lithium deposition. This innovative approach provides a cost-effective alternative to expensive metals like Au and Ag, making it a potential candidate for large-scale applications in the lithium battery industry.

Specification

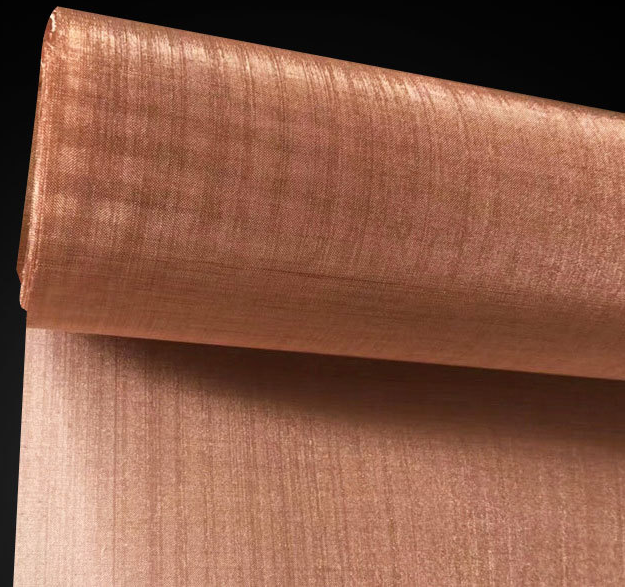

Material |

Phosphorus copper wire |

Craft |

Plain weave, Twill weave, Embossing |

Mesh count |

1 - 500 mesh (Due to limited drawing technology, the highest mesh count for brass and purple copper mesh is currently up to 200 mesh, while phosphorus copper mesh can be produced from 1-500 mesh) |

Wire diameter |

0.03-5mm |

Aperture |

0.029-50mm |

Width |

0.914, 1, 1.2, 1.3, 1.5, 1.8, 2, 2.5 (Can be processed into narrower widths down to 3mm upon customer request) |

Length |

Generally 30m for stock, but production can be extended based on customer requirements, up to 180m |

Applications |

Phosphorus copper mesh has versatile applications in industries such as mining, metallurgy, construction, and pharmaceuticals for sieving purposes. |

To customize various metal foams, please click the picture below for details:

ru

ru

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com